3D Printing PCB Components: Revolutionizing Electronics Manufacturing

By:PCBBUY 02/24/2025 14:17

Introduction

The advent of 3D printing technology has brought about a paradigm shift in various industries, including electronics manufacturing. One of the most promising applications of 3D printing in this field is the production of Printed Circuit Board (PCB) components. This article delves into the intricacies of 3D printing PCB components, exploring the underlying principles, necessary chemical processes, and the advantages it offers over traditional manufacturing methods. We will also provide detailed data and comparative tables to illustrate the efficacy and potential of this innovative approach.

The Principles of 3D Printing PCB Components

Understanding 3D Printing Technology

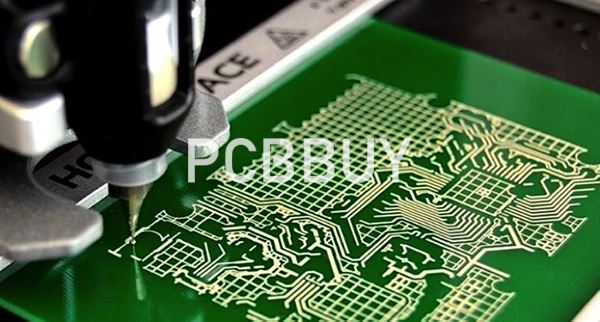

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by layering material based on a digital model. In the context of PCB components, this technology allows for the precise deposition of conductive and insulating materials to form intricate circuit patterns.

Types of 3D Printing Techniques for PCBs

Several 3D printing techniques are employed in the fabrication of PCB components, each with its unique advantages:

1. Fused Deposition Modeling (FDM): This method involves extruding thermoplastic materials layer by layer. Conductive filaments can be used to create circuit traces.

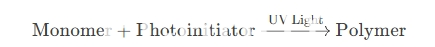

2. Stereolithography (SLA): SLA uses a laser to cure liquid resin into solid layers. It is known for its high precision and smooth surface finish.

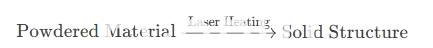

3. Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered material, creating solid structures. It is suitable for producing complex geometries.

4. Inkjet Printing: This technique deposits conductive inks onto substrates to form circuit patterns. It is highly versatile and allows for multi-material printing.

Chemical Processes in 3D Printing PCBs

The chemical processes involved in 3D printing PCB components are crucial for ensuring the functionality and durability of the final product. Key processes include:

1. Curing and Polymerization: In SLA and inkjet printing, UV light is used to cure photopolymer resins, transforming them from liquid to solid states. The chemical reaction can be represented as:

2. Sintering: In SLS, the laser heats the powdered material to just below its melting point, causing the particles to fuse together. The process can be represented as:

3. Conductive Ink Formulation: Conductive inks used in inkjet printing typically contain metal nanoparticles (e.g., silver or copper) dispersed in a solvent. The formulation ensures proper conductivity and adhesion to the substrate.

Advantages of 3D Printing PCB Components

Design Flexibility and Customization

3D printing offers unparalleled design flexibility, allowing for the creation of complex and customized PCB layouts that are difficult or impossible to achieve with traditional methods. This is particularly beneficial for prototyping and low-volume production.

Rapid Prototyping and Time Efficiency

The ability to quickly produce prototypes significantly reduces the development cycle. Design iterations can be implemented and tested in a matter of hours, accelerating the time-to-market for new electronic products.

Material Efficiency and Waste Reduction

Additive manufacturing is inherently more material-efficient than subtractive methods. It minimizes waste by using only the necessary amount of material to build the component, leading to cost savings and environmental benefits.

Cost-Effectiveness for Low-Volume Production

For low-volume production runs, 3D printing can be more cost-effective than traditional manufacturing methods. It eliminates the need for expensive molds and tooling, making it an attractive option for startups and small businesses.

Data and Comparative Analysis

Performance Metrics

To evaluate the performance of 3D-printed PCB components, several metrics are considered, including electrical conductivity, mechanical strength, and thermal stability. The following table compares these metrics for 3D-printed and traditionally manufactured PCB components:

|

Metric |

D-Printed PCB Components |

Traditional PCB Components |

|

Electrical Conductivity |

90-95% of bulk material |

95-98% of bulk material |

|

Mechanical Strength |

80-90% of bulk material |

95-98% of bulk material |

|

Thermal Stability |

Up to 150°C |

Up to 200°C |

Cost Comparison

The cost comparison between 3D printing and traditional methods for producing PCB components is presented in the table below:

|

Production Volume |

3D Printing Cost (USD) |

Traditional Manufacturing Cost (USD) |

|

1-10 units |

50-100 |

500-1000 |

|

11-100 units |

500-1000 |

2000-5000 |

|

101-1000 units |

2000-5000 |

10000-20000 |

Environmental Impact

The environmental impact of 3D printing versus traditional manufacturing methods is assessed based on material waste and energy consumption:

|

Aspect |

3D Printing |

Traditional Manufacturing |

|

Material Waste |

5-10% |

20-30% |

|

Energy Consumption |

10-15 kWh/kg |

20-25 kWh/kg |

Case Studies and Real-World Applications

Prototyping in Consumer Electronics

A leading consumer electronics company utilized 3D printing to prototype a new smartwatch. The ability to quickly iterate designs and test functionality reduced the development time by 40%, resulting in significant cost savings.

Customized Medical Devices

In the medical field, 3D printing has been employed to produce customized PCB components for implantable devices. The precision and flexibility of 3D printing allowed for the creation of patient-specific designs, improving the efficacy and safety of the devices.

Aerospace Applications

Aerospace manufacturers have adopted 3D printing for producing lightweight and high-performance PCB components. The reduced weight and enhanced design flexibility contribute to improved fuel efficiency and overall aircraft performance.

Future Prospects and Challenges

Advancements in Materials

Ongoing research is focused on developing new materials with enhanced properties for 3D printing PCB components. Conductive polymers, nanocomposites, and advanced ceramics are among the promising materials being explored.

Integration with Other Technologies

The integration of 3D printing with other advanced technologies, such as artificial intelligence and the Internet of Things (IoT), holds great potential. Smart manufacturing systems can optimize the printing process in real-time, further improving efficiency and quality.

Addressing Limitations

Despite its numerous advantages, 3D printing PCB components faces certain limitations, including lower conductivity and mechanical strength compared to traditional methods. Continued research and development are essential to overcome these challenges and fully realize the potential of this technology.

Conclusion

3D printing PCB components represents a transformative approach to electronics manufacturing, offering significant advantages in terms of design flexibility, rapid prototyping, material efficiency, and cost-effectiveness. While there are challenges to be addressed, the ongoing advancements in materials and technology promise a bright future for this innovative method. As the industry continues to evolve, 3D printing is poised to play a pivotal role in shaping the next generation of electronic devices.

Industry Category