4 Methods of PCB layout preparation

By:PCBBUY 07/03/2021 17:30

Without having effective PCBs layout prepared, there are chances that the end product will be a board that doesn’t function as desired. The truth is that having a plan or layout prepared plays an essential role in the board’s layout results. First, a PCB layout can assist in streamlining the design process through the determination of design constraints.

The above is not all. With a layout in place, matters to do with sizing and the placement of vital elements such as maximum and minimum tolerances get determined way back before production. A lack of a layout may demand extra costs, time, and money needed to correct errors. A PCB layout preparation comes with many benefits to PCB manufacturers who intend to avoid unnecessary costs associated with having to correct previous errors.

Coming up with some of the most functional, reliable, and cost-effective PCBs can be a very tasking exercise. However, having a PCB layout prepared beforehand, rest assured of having a product that will meet all your needs. A PCB layout avoids plenty of unpleasant experiences associated with such boards, especially when they are already in the market and used.

1. What are problems of lack of PCB layout preparation?

Many issues are bound to emerge from the lack of accurate or efficient PCB layout preparation. A bigger problem that is probable to arise from a lack of PCB layout preparation is total board failure. Board failure comes in as the most significant issue that arises from poor planning or a lack of PCBs layout preparation reported by many individuals.

Apart from board failure, another issue that can arise from lack of PCB layout preparation is that it may lead to manufacturer rework. Without adequate PCB layout preparation, your board will go back to the manufacturer or designer for rework, an aspect that causes delays. Much worse, most boards that go back to the “drawing board” fail to work as desired or intended. Shipping it back is an aspect that increases costs while extending lead times.

A PCB board's limited functionality is another issue that arises from boards manufactured without factoring in PCB layout preparation. Producing or manufacturing printed circuit boards while ignoring the initial specifications will not function in the right manner. Here, functional or quality issues may surface, which can limit or inhibit the board's capabilities or functionality.

2. How to meet the requirements of PCB layout preparation?

There’s a huge demand in the PCBs market, but not just any boards but quality boards made under the right procedures. PCBs are manufactured once a layout is prepared to attract a huge market. Therefore, designers and manufacturers are under pressure to manufacture boards that promise to bring about desired functionality regularly.

Plenty of PCB manufacturers –OurPCB included- lately, employ effective tools such as DFM software and PCB design tools to create the best layout plans. Such tools are effective as they bring about the best solutions for creating the best PCB layout. These and many other tools find use in a lot of PCB manufacturing firms since they are cost-effective and functional to PCB designers and manufacturers.

To meet the demands of producing functional PCBs that deliver as desired, many manufacturers are heavily concentrating on having layout prepared first. This includes defining the board's outline, placing the parts together, creating connections between the parts, and exporting them for fabrication. PCB layout preparation matters in producing high-functioning PCBs, a reason why plenty of PCB manufacturers lately consider this matter seriously.

3. What are the considerations of PCB layout preparation?

PCB layout preparation is considered somewhat an art form by circuit manufacturers, and to say the least, there’s a lot of truth to that. We at OurPCB understand that coming up with a functional, reliable, yet cost-effective PCBs is not an easy task as such. The demand for light-weight, compact, and flexible boards is also making everything appear more challenging.

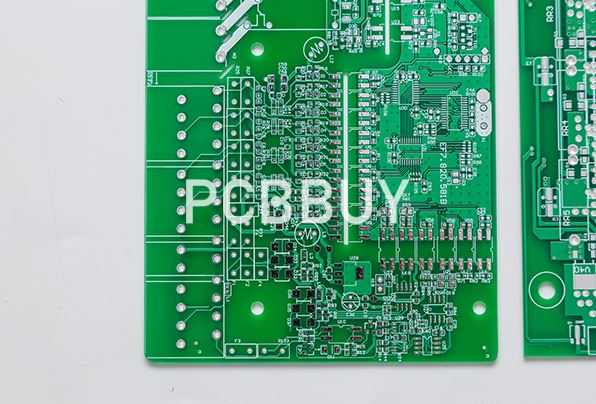

The biggest consideration in PCB layout is shape and size, with the result supposed to accommodate the environment where the board will find applicability. Space considerations may require boards that consist of high-density or multi-layer interconnect designs. Some require boards of certain shapes or weight, making layout preparation challenging.

Lately, there is a demand for flexible PCBs in nearly all places across the globe. Sadly, not all PCB manufacturers/designers can ensure that they achieve layout design for flexible PCBs with ease. Additionally, plenty of them fails when it comes to the type of material requirements that will fit the layout well. Such factors are a higher priority when deciding PCB layout preparation for production manufacturing.

4. What are the complex PCB layout preparation issues?

Creating a circuit board withstand even some of the toughest conditions is not an easy process as one may like to imagine. While PCB layout preparation matters, such can be impeded by technical or rather complex PCB layout preparation issues. Some of the most common technical/complex factors in PCB layout preparation include:

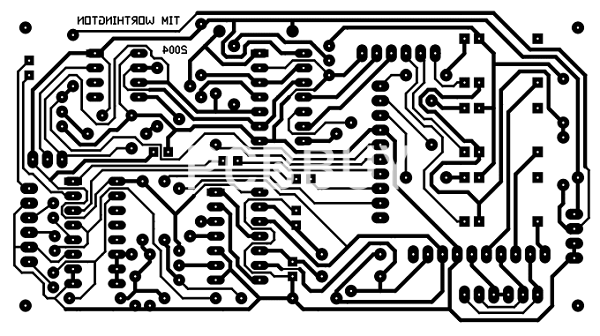

· Coming up with the best layout needed for spacing between traces

· Trace widths

· Tolerances for the electrical factors that may affect the functionality of the board

· Clearance of traces in addition to other components to the edge of the board

The availability of some layout components may be a tasking exercise with specialized or hard-to-find components likely to increase the final product's cost. If the production of a high number of boards is necessary, this can also be a major concern.

PCB layout preparation largely depends on the construction methodology or the physical construction of the board. For instance, HDI and multi-layered designs have increased significantly in recent years which have plenty of specific layout requirements. Others include flexible PCBs that are completely altering the way manufacturers handle layout preparation before final product creation.

Industry Category