4 layer pcb cost

By: 01/04/2024 15:17

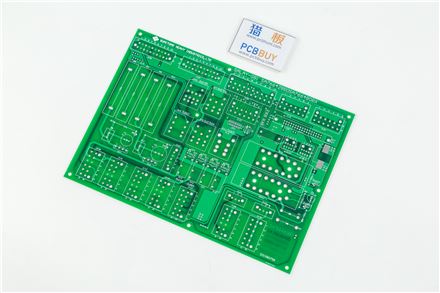

In electronic manufacturing, multilayer printed circuit boards (PCBs) represent a critical component, particularly in high-end products or complex systems. Among the various types of PCBs, the cost structure of a 4-layer PCB warrants an in-depth exploration. This article aims to meticulously dissect the cost composition of a 4-layer PCB and conduct a comprehensive analysis.

I. Engineering Fees

Engineering fees constitute a significant cost in PCB production, encompassing the entire process from design to fabrication. Specifically, these fees cover tasks such as circuit design, component layout, layer stacking design, and manufacturing parameter settings. Professional engineers undertake these tasks, hence the level of engineering fees directly correlates with the experience and skill levels of the engineers. Generally, PCBs designed by highly experienced engineers offer better performance and stability, thus commanding relatively higher engineering fees.

II. Fabrication Costs

Fabrication costs are one of the pivotal expenses in PCB manufacturing, inclusive of material procurement, equipment operation, quality testing, and other associated costs. The magnitude of fabrication costs hinges on several factors:

Material Costs: The prices of materials required for PCB fabrication, such as copper foils, resins, directly influence fabrication costs.

Equipment Depreciation: Production machinery undergoes wear and tear over prolonged use, necessitating depreciation considerations, which also contribute to fabrication costs.

Quality Testing: Multiple inspection procedures are essential to ensure PCB quality, and these constitute an integral cost component.

III. Photoplotting Fees

Photoplotting involves transparent plastic film used to transfer circuit patterns during the manufacturing process. Photoplotting fees encompass the purchase cost of the film and associated processing expenses. As photoplotting materials are consumable, their costs are significant. Moreover, the quality of the photoplotting film impacts PCB manufacturing costs. Higher-quality photoplotting materials enhance manufacturing precision, thereby reducing defect rates.

IV. Testing Costs

Testing stands as a crucial phase in ensuring PCB performance and quality. Testing costs comprise expenses related to equipment depreciation, test program development, and labor. With ongoing technological advancements, the significance of testing procedures is increasingly pronounced, leading to a gradual rise in their proportion within the overall cost structure.

V. Miscellaneous Expenses

Apart from the aforementioned major cost components, additional expenses like transportation, storage, taxes, etc., though relatively minor, warrant attention. Particularly in the international market, various taxes and transportation costs might significantly influence the final costs.

In conclusion, the cost of a 4-layer PCB primarily comprises engineering fees, fabrication costs, photoplotting fees, and testing fees. These expenses are interconnected, and optimizing any aspect could positively impact overall costs. Therefore, during the production process, a comprehensive consideration of expenses is essential. Employing scientific management and optimization to reduce overall costs enhances a product's market competitiveness. Additionally, for electronic manufacturing enterprises, comprehending and analyzing the cost composition of PCBs serves as a vital basis for devising production strategies and conducting price calculations.

If you want to order PCB product, please check and custom your order online.

Industry Category