5 Aspects of Fr4 PCB Material Properties to Learn PCB Basic Knowledge

By:PCBBUY 09/30/2021 10:59

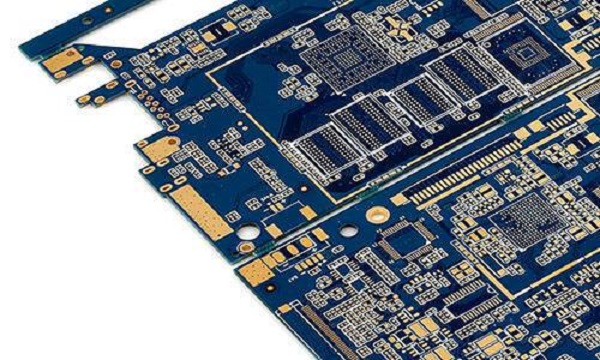

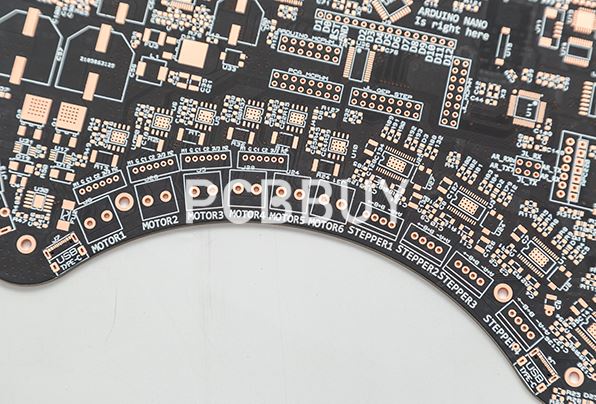

FR4 is the most common material grade that comprises fabricated circuit boards. ‘FR’ indicates the material is flame retardant and the ‘4’ indicates woven glass reinforced epoxy resin. Single or double-sided PCB structures consist of an FR4 core and top and bottom copper layers. Multilayer boards have additional prepreg layers between the center core and top and bottom copper layers. Now, the core consists of a substrate with copper covering, also referred to as a copper clad laminate. The core, laminate, and prepreg may all be FR4 with the copper sheets between the signal and ground layers.

Are you going to learn the professional knowledge about Fr4 PCB material? You can check and read the content for more information about Fr4 PCB material.

What are the 5 aspects of Fr4 PCB material properties?

1. Why choose Fr4 PCB material?

The affordable cost of FR4s make them a standard option for the production of small series of PCBs or for electronic prototyping.

However, FR4 is not ideal for high frequency printed circuits. Similarly, if you want to build your PCBs into products that do not easily allow the adoption of components and that are little suited to flexible PCBs, you should prefer another material: polyimide/polyamide.

2. What are the properties of Fr4 substrate?

The FR4 printed circuit boards have also gained popularity owing to the following reasons:

· FR4 is a low-cost material.

· It has a high dielectric strength which contributes to its electrical insulation properties.

· The material has a high strength-to-weight ratio and is lightweight.

· It is moisture resistant and has relative temperature resistance as well.

· The material has good electric loss properties.

· FR4 doesn’t absorb water, which makes it suited for various marine PCB applications, too.

· The material is yellow to light green in color, which perfectly goes with any application.

Chemicals that are applied to materials to prevent or delay the spread of fire are known as flame retardants. FR4 substrates have excellent thermal, mechanical, and electrical properties making them a perfect choice for a wide range of electronic applications. Flame retardant laminates and prepregs are extremely versatile, adaptable to a variety of manufacturing procedures, and produce predictable results.

The electrical properties of a PCB material are critical for signal integrity and impedance considerations. They specify how fast an electrical signal propagates through the material and how much electrical charge it can retain in a given volume.

3. How to select thickness of Fr4 material?

When ordering a laminate board for a PCB project, the designer or electrical engineer must specify the FR4 PCB thickness. This is measured in inch-based units, such as the thousandth of an inch, or thou, or millimeters, depending on which is most appropriate for the setting. The thickness of a sheet of FR4 ranges widely depending on the needs of the project, but it tends to range from ten thou to three inches.

While board thickness may not seem like a significant factor in the design of a PCB, in reality, it is an essential feature. Board thickness affects several aspects of the board’s functionality, which is why several factors are considered in determining the thickness of a board for design.

If space concerns the designer, a thinner FR4 board tends to be preferable. This is a predominant factor for the manufacture of smaller devices, like USB connectors and many Bluetooth accessories. Even for larger projects, smaller FR4 PCBs tend to be favored to save space within the device.

4. What are the design requirements of Fr4 material?

Thin boards aren’t preferable in all cases, primarily due to the limitations thin boards put on PCB plans. Thin FR4 boards can’t feasibly feature grooves, and they can’t be too large without risking fracture. Thicker boards, however, can accomplish both. Always account for this when weighing options between FR4 thicknesses.

The thickness of a board can also affect the compatibility of components with the board. Just like edge connectors, many components work with a small range of board thicknesses. This is especially true for some through-hole components, for example.

5. What are others considerations of Fr4 material?

The material is mechanically strong, rugged, and stable. As a result, holes cannot be punched; instead, they must be drilled. The glass-epoxy material is very tough on drill bit life, and also on the shears used for trimming or cutting boards. These are factors which make fabrication using FR-4 PC boards more costly than it is with phenolic ones, in addition to raw material cost.

Industry Category