5 Best Solder Tip for PCB - How to Do PCB Soldering?

By:PCBBUY 09/16/2021 09:22

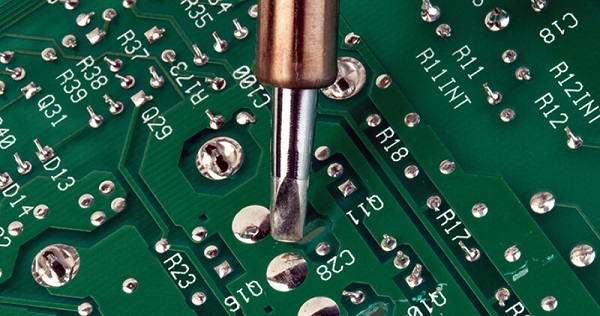

PCB soldering is another term for the process of soldering electrical circuit boards. This type of soldering is one of the most basic techniques that anyone wishing to work with electronics and electrical circuits must learn. While there are many different ways you can complete the soldering process, the most basic explanation of the soldering process is that it’s a way of joining two small pieces together on the surface of the PCB, which stands for PCB.

In other words, soldering is a way of connecting two or more different electrical components on your circuit board. In this passage, we will focus on the best solder on PCB, if you are going to learn the knowledge of it, please check and read the content below for more.

If you want to order PCB product, please check and custom your order online.

What are the different technologies of PCB soldering?

Soft Soldering

Soft soldering is a process used for attaching small components onto the larger PCB. These small components will usually have a low-liquefying temperature that will begin to break down under the high temperatures of the heat source. Rather than simply melting the component, however, an additional step must be used to attach the component to the board. In this case, this extra step is a filler metal, which is typically a tin-lead alloy.

Hard Soldering

Hard soldering is a process that uses a solid solder to join two different metal elements together by spreading throughout the holes of the components that become unlocked as they’re exposed to high temperatures. As a process, hard soldering is made up of two smaller sub-processes known as silver soldering and brazing.

What are the 7 tips of processing best PCB solder?

1. What is the difficulty of best PCB soldering?

Here’s the problem: Training focuses on the desired appearance of solder rather than how the connection is achieved. And “acceptable” appearance may hide failures in waiting. How the connection was made determines not only whether the solder connection itself is reliable but whether catastrophic damage was inflicted on the component being soldered. At soldering iron temperature, solder will stick to oxides and contaminants to produce a visually acceptable connection.

2. What are the PCB soldering defects?

The ban on lead in electronics changed our business profoundly by eliminating tin/lead component surfaces. Meanwhile, tin plating has become increasingly uncommon because of concerns about tin whiskers with pure tin. The new component surfaces are not tin or tin/lead; they are metals with higher melting temperatures that do not reflow during application of the solder. In other words, these are metals that are soldered, not reflowed. And the surfaces must be thoroughly deoxidized before solder is applied.

3. How to avoid soldering bridge?

A solder bridge is formed when two points on the circuit board that should not be electrically connected are inadvertently connected by solder during PCB soldering. This will form an electrical short circuit, which may cause various damages, depending on the circuit structure. A solder bridge can be fixed by holding your solder iron in the middle of the bridge to melt the solder, and drawing it through to break the bridge. If the solder bridge is too large, excess solder can be removed a solder sucker.

4. What is the diameter of PCB best soldering?

The gauge number determines the diameter of the solder. A gauge number is a unit of thickness for metal sheets and wires. For amateur and hobbyists, gauge numbers 18, 20, and 21 are the numbers that work well. The diameters of these numbers are 1.22, 0.914, and 0.813 mm, respectively. Staying in this range is a good idea for amateurs and beginners. Using wires of this diameter reduces solder wastage.

5. How to base on chemical contents of PCB best soldering?

Using these materials enables you to personalize the solder based upon your requirements.

There are only three primary categories of solders to which you can narrow your search.

· Lead solders were, for a long time, the go-to substance in the electronics industry. The most commonly existing blend is the 60/40 (tin/lead) blend. Tin helps maintain a lower melting point.

· Lead-free solders have started gaining popularity. The primary reason is the fact that the EU restricted the use of lead in electronics. In countries like the US, manufacturers receive tax relief for using lead-free solders.

· Flux core solder, sold as a single reel, consists of a reducing agent at the core. During the process of soldering, the flux gets released. This flux reduces the metal at the point of contact, which results in a cleaner and neater connection.

Industry Category