5 Effective Methods for PCB Interconnect Solutions in PCB Design

By:PCBBUY 11/04/2021 09:47

As a part of the whole machine, a printed circuit board generally cannot constitute an electronic product, and there must be a problem of external connection. Electrical connections are required between circuit boards, circuit boards and off-board components, printed circuit boards and equipment panels. The selection of the best combination of reliability, process and economy is one of the important contents of PCB board design. There are many ways to connect externally, and you have to choose flexibly according to different characteristics.

In this passage, we are going to provide you all the details about effective methods of PCB interconnect. If you are going to learn more about PCB interconnect, please check and read thr content we prepare below.

1. What are the advantages of high density PCB interconnect?

These PCBs are extremely compact. Considering that HDI PCBs have a higher wiring capacity, they are one of the best options for engineers looking for the smallest circuit board with the largest output. HDI capacity makes it easier to turn a 10 layered PCB into a four or five layered one, which is great for those looking for smaller boards without skimping on quality. Since most consumers prefer small devices, this can be a huge design advantage.

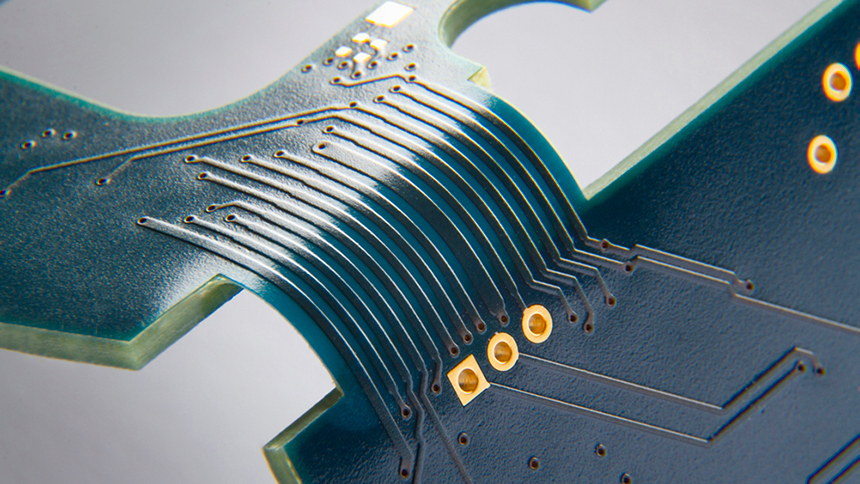

The ability to place more components on one side. These HDI PCBs utilize blind and buried vias, and Via-in-Pad technology, as methods of placing components closer together, which results in faster signal transmission. Making it an ideal technology for RF circuits.

Laser drill technology makes PCBs into advanced electronic circuits. This manufacturing technique allows for smaller holes to be used and gives the board higher heat resistance.

2. How to solder PCB trace?

This method does not require any connectors, as long as the wires are used to directly solder the external connection points on the PCB printed board to the components or other components outside the board. For example, a speaker in a radio, a battery case, and the like.

Pay attention to the interconnection of the board when soldering:

· The pads of the soldered wires should be as close as possible to the edge of the PCB printed board and arranged in a uniform size to facilitate soldering and maintenance.

· In order to improve the mechanical strength of the wire connection, to avoid the wire or the printed wire being pulled off due to the pulling of the wire, the hole should be drilled near the solder joint on the PCB printed board, so that the wire is worn from the soldering surface of the printed board. Through the via hole, insert the pad hole from the component surface for soldering.

· Arrange or bundle the wires neatly and fix them with the plate by wire cards or other fasteners to prevent the wires from breaking due to movement.

3. How to determine types of the PCB interconnect?

Whether you plan to create vertical towers of PCBs stacked on top of each other, or need to load multiple boards into racks to fit into a server, designers have many options when it comes to the types of connectors that are available.

Standard Board Interconnects

Male/female, pin/socket headers are the most common type of board-to-board connector out there. Available at a low cost, these interconnects are popular for breadboarding and Arduino kits.

Backplane Connectors

A typical backplane is a PCB with no active components. Its primary purpose is twofold: provide structural integrity to the multi-board system and serve as a surface for multiple daughter boards to connect to.

Card edge connector: Often used as expansion slots on motherboards, backplanes or riser cards, edge connectors are designed to mate with the conductive traces lining the edge of another board (e.g. PCI-e slots).

Wire-to-board

Need to connect cables or wires to a board? FFCs (flexible film cables), FPCs (flexible printed cables), high-speed internal cabled interconnects, and ribbon connectors are just a handful of the options out there.

4. How to handle PCB socket interconnect?

This interconnection is often used in more complex instruments and devices. This method makes the printed plug from the PCB edge, and the plug part is designed according to the size of the socket, the interconnection points, the contact distance, the location of the positioning holes and so on, so as to make it match with the special PCB socket.

When manufacturing PCB, the plug part needs to be gold-plated to improve wear resistance and reduce contact resistance, which has the simple assembly, great interchangeability, good maintenance performance, and is suitable for standardized mass production. The disadvantage of this method is that the cost of PCB is increased, and the requirements of PCB manufacturing precision and process are higher. In addition, its reliability is poor. For example, it often lead to poor contact because the plug part is oxidized or socket spring aging. In order to improve the reliability of external interconnection, the same outgoing line is often drawn out in parallel through the contacts on the same side or both sides of PCB.

5. What are the basic design considerations of PCB interconnect?

Putting a good PCB plan on "paper" starts with having the right overall product goals, market/customer insight and target specifications. From this starting point, you can begin to design the circuit boards and other components that need to work together.

When working with the design software, simplify your view to see split planes and return paths between the boards. If the digital signal must cross a split in the power reference plane, use one or two plane decoupling capacitors (100nF) to close the offending signal.

Another rule of thumb is to avoid routing traces in parallel and broadside as they cause greater amounts of PCB crosstalk than those routed perpendicular. Since traces are wider than they are thick, they pick up more radiation when on top of each other.

Industry Category