5 Essential Tips about PCB Annular Ring Calculator during PCB Drilling

By:PCBBUY 10/30/2021 10:03

The annular ring surrounding the via facilitates the connection between the trace and the via. What this means is the thicker the annular ring, the stronger the connection. But how thick should the annular rings be, and how do you calculate it?

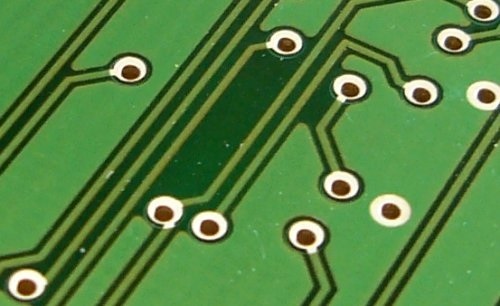

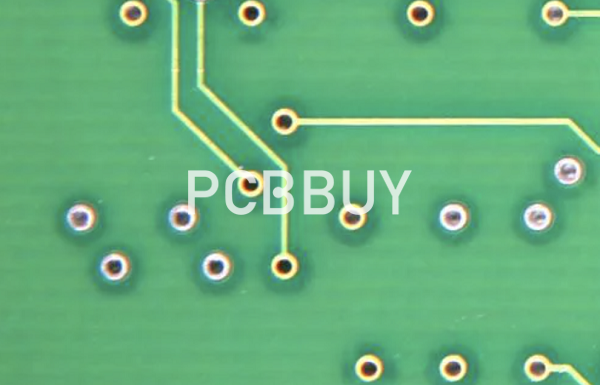

When you drill a hole into a copper PCB pad, the resulting copper surrounding the hole is what we know as annular rings. It essentially acts as the wall of the drilled via. Your annular ring size will depend on the size of the via and the size of the copper pad’s size.

If you are interested in PCB Annular Ring, please check and read the content below for more detailed information.

If you want to order PCB product, please check and custom your order online.

1. Why PCB annular ring calculator is important?

As we all know, that annular rings are meant to connect the PCB with a reliable electrical connection. Thus, in a foremost way, the ring size must allow cords to pass through it easily. Also, another thing to pay attention to is that the minimum size of the annular ring shall be greater than or equal to the overall specified design.

If any of the above conditions do not meet, it results in discrepancies called “Tangency”, “breakout”, and undesired annular ring. One of the prime factors to remember when constructing a PCB board is that all the annular rings shall be carefully crafted. Only this will result in the proper working of the circuit.

2. How to process teardrop annular ring?

Tear Drop PCB is named as such due to the unique shape it possesses. These types of annular rings are a common feature in the teardrop pads. One of the prime aspects of these pads is that this type of shape increases the overall structural integrity against all types of stress.

Apart from all these benefits, the teardrop shape also increases the tolerance in the pad. Also, the teardrop annular rings are a match for conductors, which have a width of fewer than 20 mils.

3. What are the considerations of PCB annular ring calculator?

Different fabrication houses will undoubtedly use varied and differing manufacturing technologies and equipment. Average performance houses may offer design specifications allowing a 10mil minimum annular ring. High performance houses may be able to reduce that figure down to 5mil. If pad and via holes are laser-drilled, as opposed to mechanically drilled, then the value for the minimum annular ring may be reduced further still.

The class of board you are designing will also play a part in the value required for the minimum annular ring. For example, if your design is of IPC Class 3 standard, which refers to high reliability electronics products, the required minimum annular ring is 2mil. If you do have to reduce the annular ring below the accepted standard of the fabrication house, try to limit the usage of such affected pads and vias. The more pads and vias on the board that use such annular ring specifications, the more chance there is of a board failing during the fabrication process.

4. What is the application of PCB annular ring?

Annular rings are integral elements of a PCB as they create room for solid electrical connections on a board. Without these rings, you will be unable to create reliable connections on your PCB. Issues related to annular rings are problematic and significantly affect the trace continuity and the functionality of the entire board.

Unfortunately, some designers ignore the importance of annular rings by creating distorted shapes. When designing annular rings, you should be accurate to avoid drilling off the mark. By doing so, you will eliminate the annular ring tangency.

5. How to calculate PCB annular ring?

While manufacturers are responsible for producing accurate annular designs, designers also have their role in creating the correct size designs. Incorrect ring sizes will negatively affect the functionality of the whole PCB. Therefore, you should state the appropriate annular ring sizes to obtain a quality and functional product.

You can use PCBs in various applications, like home appliances, military, and medical equipment – based on their thermal capacities and insulating properties. Therefore, when calculating the annular ring of your PCB, you should consider its application.

If your PCB is for special applications, like the military, it may require high-quality PCB annular rings. PCBs are classified into three classes: levels 1, 2, and 3. Level 3 boards are used in heavy applications; hence, Class 3 annular ring requirements differ from Class 1 and 2. Their pad size is a bit large to house the vias’ diameter.

Calculating the PCB annular ring is not a simple task. The correct annular ring width is the difference between the finished aperture’s diameter and the copper pad divided by two. Assuming the pad diameter is 40 mils, and the hole diameter is 10 mils, then the annular ring is calculated as shown below:

(40 -10)/2 = 15 mils.

Industry Category