5 Essential Tips of Electronic Components Replacement Guide in PCB Project

By:PCBBUY 03/08/2022 10:28

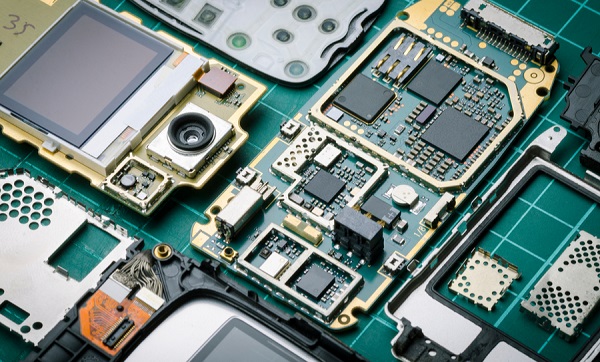

Repairing a circuit board is often more than finding a circuit breaking. Electrical equipment and service panel tinkering can go so far but spare and replacement may get your device working thoroughly again. Fortunately, there are simple strategies and software solutions that can help you choose replacement components for your PCB.

If you are searching for more information about electronic components replacement guide in PCB, please check and read the content below for professional knowledge.

Why components need replacing?

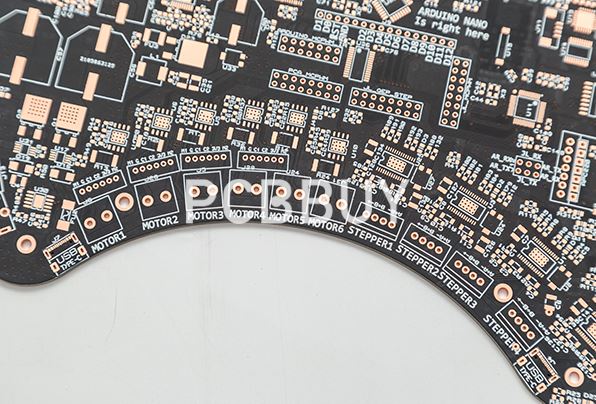

PCB layout constraints

When a circuit board is designed, the components soldered to it are represented by schematic symbols and footprint models in the PCB design CAD system. Each schematic symbol type has a unique part number assigned to it to differentiate it from other similar symbols, as in two resistors with different values. This part number identifies the component’s type and value and is forwarded into the bill of materials (BOM) to purchase the correct parts for PCB assembly. When a component is replaced in the design, that schematic symbol must be updated with the new part number and device attributes. Simultaneously, the corresponding PCB footprint will be altered to model the new package if the physical part has changed.

Components are often swapped around during the design process until the final circuit configuration is decided. Once the design is completed, however, components are usually not replaced except for the following reasons:

· Design problems: Errors discovered during production may require the replacement of a part. Issues like these could be related to the performance of the board or in how it is manufactured. The replacement could be something as simple as changing the value of a capacitor or as complex as physically redesigning some critical circuitry layout.

· Unavailable parts: During production, a part may become unavailable for several reasons:

· Another OEM has bought out all the stock of a specialty part.

· The lead-time is too significant for the project’s needs.

· The component manufacturer is unable to keep up with demand.

· The part was phased out in favor of a more common component with similar functionality.

· The part was discovered to have a defect or design flaw.

· The manufacturer obsoleted the part due to other business reasons.

· Expense: Components may be replaced on a production circuit board to reduce manufacturing expenses. If a part begins to escalate in price, it’s sometimes more cost-effective to redesign the board. In some circumstances, a part will be replaced with less expensive components or redesigned circuitry. However, the savings must be compelling because the production of a new circuit board will require revalidating the design for the system that it operates in.

What are the advantages of components replacing?

You can start your search for replacement parts by visiting the distributor’s and manufacturer’s websites. These listings will give you the most current information about a variety of parts as well as their datasheets. However, you should be aware that not all listings include CAD models. Some may have them, but others will not.

A CAD part library service is another resource that can help you find components. These online services often offer tools integrated into your PCB design software and native system data. For example, you may be able to access schematic symbols, 3D STEP models, and footprints of your PCB, as well as datasheets, illustrations, and datasheets, depending on which service you choose. These services will save time and give you the most accurate data models the manufacturer usually creates.

It is essential to evaluate the form, fit, and function of any component that you are replacing in your design. A slight difference in functionality can have a significant impact on your circuitry. This is where skilled component engineers and procurement experts can help. They have the experience to help you make the right decisions about component replacements because they are familiar with how components work.

How to choosing possible replacements?

As you proceed through the design process, you may find that changes need to be made mid-design, forcing you to adapt your device to new requirements. This might require choosing replacement components for your device, and you’ll want to ensure your replacements are compatible with your device functionality.

Locating replacements for basic circuit elements like resistors and capacitors is rather simple. Some specifications for these components are really maximum tolerances, and these tolerances should not be exceeded. If you opt for a replacement component with a lower tolerance, you need to check this against your device requirements. In some cases, changes to device functionality relax these tolerance requirements, allowing you to choose from a broader range of components.

When searching replacements for other components, it might be difficult to locate a replacement component that matches every possible specification you need. Not every component has the same footprint, power consumption, input/output voltage or current, and other specifications. As you browse through available components, may only be able to constrain a few of these specifications, and you will have to accept changes in others.

Before looking for a suitable replacement component, you’ll need to decide which component specifications should not change when choosing a replacement. Other specifications are really constraints or tolerances, just as in the case of simple components. Sometimes, you cannot satisfy every constraint depending on which components can be readily sourced.

Swapping a surface-mount component for a through-hole component will require changing your land pattern, which requires a redesign. If you originally designed specific pads in your PCB to support surface-mount components, then it may be a good idea to stick with it. Only switch your land design if this is the only way to accommodate a replacement component that maintains or improves the overall functionality of your PCB.

Industry Category