5 Essential Tips of Outsourcing Electronics Manufacturing in PCB Manufacturing

By:PCBBUY 03/19/2022 11:01

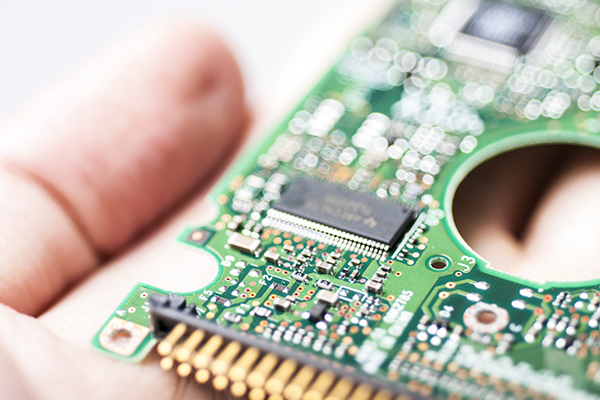

PCB manufacturing machines, surface mount machines and quality inspection machines are a massive up-front investment. So are the costs in getting certified to manufacture printed circuit boards (PCBs) for vehicle and medical projects. And the new hires you’ll surely need will cost you in permanent, monthly salaries and social insurance. Without outsourced PCB assembly, you worry about none of that. Keep your operation small, and only worry about your recent employees.

Do you know the knowledge of PCB outsourcing electronics? In this passage, we are providing all the information about PCB outsourcing electronics, please check and read the content below for more professional information.

Why we process PCB outsourcing manufacturing?

Lower investment

Surface mount machines and quality inspection machines are a massive up-front investment. So are the costs in getting certified to manufacture PCBs (printed circuit boards) for aerospace and medical projects. And don’t forget that the new hires you’ll surely need will cost you in:

· Permanent, year-round salaries

· Health insurance

· Retirement packages

With outsourced PCB assembly, you worry about none of that. Keep your operation small, and only worry about your current employees.

Facility savings

Renting or leasing warehouse space can really drain your funds, not to mention if you have to pay property taxes. That's why your electronics vendor can hold your parts in-house. You don’t have to find space for all that inventory. Your PCB manufacturer will take on the financial burden until the parts are shipped out.

This cost reduction lets you invest somewhere else in your facility -- R&D, marketing, you name it.

Cost efficiency

Your electronic manufacturing services provider should already have in place an established infrastructure and well-rehearsed operation. Why spend years attempting your own? A PCB fabrication expert will already understand the inventory management factors that affect cost efficiency, such as:

· Short part life cycles

· Price fluctuations

· Design changes

Especially if you’re a startup with little capital, it’s easier to enlist experienced and well-run circuit board assembly services instead of trying to consolidate the process yourself.

Rare expertise

The specialists will always do it better.

PCB assembly services are what the contractor focuses on day in, day out. They know the industry best and are already a step ahead of you in thinking about issues you didn't even know about:

· Lead times

· Design flaws

· Conflict materials

· Intrinsic safety

Imagine your relief when you take a project to a PCB contractor and they spot a design problem before it goes to market. Now imagine that partner offering to help you redesign or refit a board to more efficiently manufacture that product. This actually happens all the time with PCB assembly outsourcing!

Put your focus where it should be

A contracted company can take a big burden off your hands.

With an OEM’s collective hands and minds free, it can instead focus on engineering or another part of the business. Maybe your resources are better suited for marketing your product or trying to break into a new market.

Industry Category