5 Main Factors during SMT PCB Assembly Process

By:PCBBUY 10/28/2021 09:15

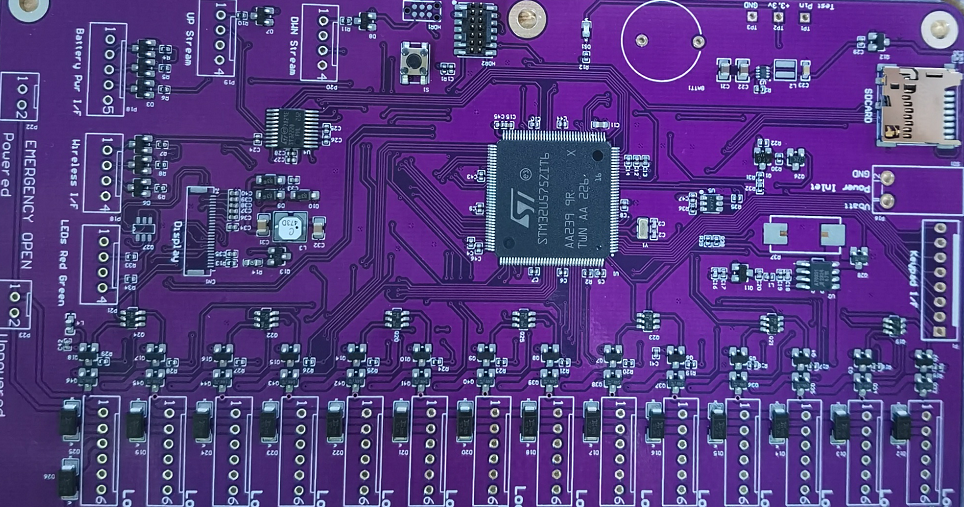

Surface Mount Technology Printed Circuit Board assembly SMT PCB refers to a process of mounting electronic components on the surface of a PCB using automated pick-and-place equipment.

These are five main factors that directly affect assembly quality, efficiency and reliability

If you are going to learn the knowledge of SMT PCB assembly, please check and read the content below.

1. What are the preparations before SMT PCB assembly?

Produced Printed circuit board (PCB)

Stencil and solder paste

Souring electronic components

2. How to solder the paste for SMT PCB assembly?

Applying soldering paste is one of the first steps in the SMT assembly process. Soldering paste is "printed" on the boards. Depending on the design of the board, different stencils for "printing" the paste onto the board and various product-specific pastes are used. Using a laser cut stencil custom made for the project, the soldering paste to be applied only to the areas where components will be soldered. After the soldering paste is on the boards, a 2D-soldering paste inspection is performed to ensure that the paste is evenly and correctly applied. Once the accuracy of the soldering paste application has been confirmed, the boards are transferred to the SMT assembly line, where the components will be soldered.

3. How to make DFM check for SMT PCB assembly?

Once a turnkey order is released to PCBBUY's production team, their very first task is the validate the design through a thorough DFM / DFA Check process. These checks include verification of consistency across different design documents (i.e. BOM, Gerbers, Centroid, etc.), part spacing, footprint accuracy, and clear orientation markings. The main objective of this procedure is to minimize as much as possible the potential for design errors to affect the finished product, which acts to protect clients against the additional time and cost involved with board-level rework.

Clients should watch for emails from PCBBUY's production team over course of the first one or two days after placing an order. If any issues or discrepancies are detected during this initial check, the production coordinator for the order in question will reach out to the client directly for resolution. Generally, an itemized report will be sent for response, and the order will be placed on hold pending full confirmation, so it is important to reply to these questions as soon as possible in order to avoid delays.

4. What is the process of SMT?

Here we divided the complete SMT soldering process into 10 steps:

· Printing solder paste

· Adhesive Dispense

· Component pick and place

· Pre-Reflow Automated Optical Inspection (AOI)

· Reflow Soldering

· Post-Reflow Automated Optical Inspection (AOI)

· Conformal Coating

· Final Inspection and Functional Test

· Washing & Drying

· Packaging & Shipping

5. What are the uses of SMT?

SMT assembly was born as a way to create a better, more powerful electronic product.

One look around your office or living room will show you several common surface mount technology applications. Basically, turn to surface mount PCB assembly whenever you need a product that is

· Smaller

· Lighter

· Faster

· More powerful

While through-hole is still used in certain applications or even certain locations on a board, SMT assembly has largely taken over

Industry Category