5 PCB Assembly Instructions to Guarantee the Quality

By:PCBBUY 09/18/2021 09:29

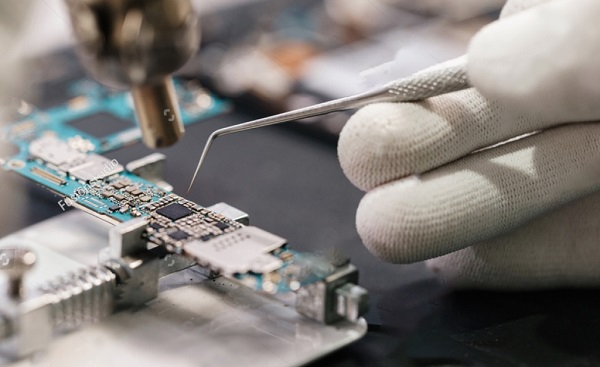

For PCBA , all of the necessary information that describe how your board should be built in proper way. For assembly and design intent, you can optimize manufacturing efficiency by following a set of best practices that employ transparency and completely convey all necessary details within your assembly drawing or PCB assembly instructions.

In this passage, we will tell you the main instructions of PCB assembly. And if you are interested in the methods to guarantee the quality of finished PCB, please check and read the content below for more information.

What are the 5 main PCB assembly instructions?

1. What are the requirements of PCB assembly?

PCBA quality will depend on your CM’s manufacturing process, especially its adherence to industry standards. And while PCBA performance and reliable operation are primarily design issues, structural integrity and component mounting—as well as the mechanical ability of your boards to remain intact over their projected operational lifecycle—are CM responsibilities that define board quality and contribute significantly to operational reliability.

PCB Assembly Instruction Requirements

· Be sure to include the board revision and other identifiers, such as publishing date, that clearly distinguish this design.

· Specify any components or areas of your board that need special attention—for example, polarization, moisture sensitivity and keep-outs.

· Ensure that any process or readability requirements for silkscreen layer reference indicators, labels and markings are included.

· Make sure that footprints on your PCB layout are accurate for the MPNs in your BOM component listing.

2. What are the benefits of PCB assembly?

These are some benefits of Automation PCB Assembly:

Lower total cost

Using automated PCB assembly means you can expect lower overall costs. Many SMT assemblers use the exclusive circuit board assembly program before actual production. This is to reduce the risk of errors and delays.

Short product development cycle

The time invested in manual assembly may vary depending on the circuit board that produces inconsistent time frames for completion. Hand-assembled PCBs may take longer to develop, which can be counterproductive if you have several other operations that you could complete at the same time.

Consistent quality

As an automated machine is designed and programmed to perform the same task repeatedly, the precision and quality of the circuit boards can be better and more consistent than manual assembly.

3. What are the special technologies during PCB assembly?

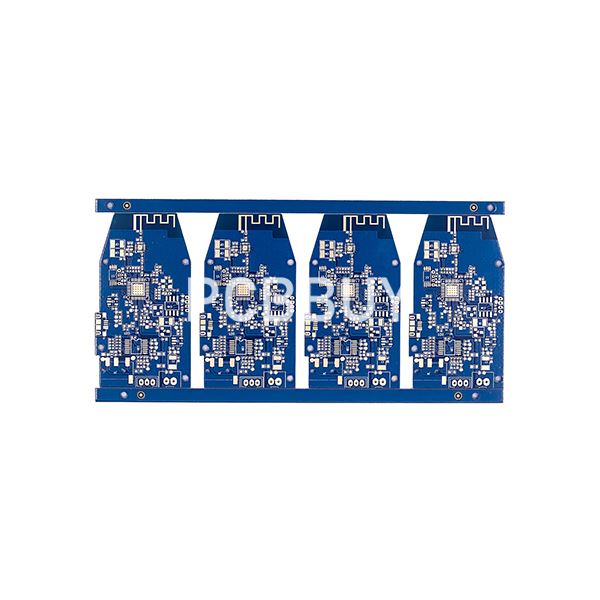

With the development of modern science and technology, electronic products are becoming increasingly complex, driving complicated, integrated and smaller size PCB boards. It is almost impossible for PCBAs containing only one type of component taking part in.

Most boards carry Thru-hole components and SMD components, which requires collaboration of thru-hole technology and surface mount technology. Nevertheless, soldering is a complicated process that tends to be affected by too many elements.

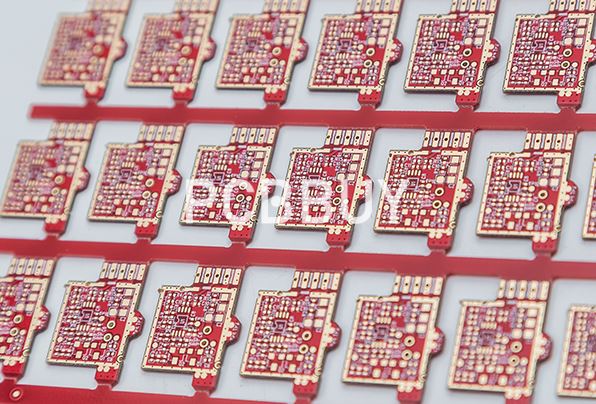

With SMT printing technology, there will come novel manufacturing methods of printed circuit boards for better system integration, cost-saving, and lightweight boards. Additionally, SMT printing technology will bring about new assembly possibilities, shorter development times, and new assembly technologies.

4. What is the overview of PCB assembly?

· Solder Paste: If you’re following a traditional PCB assembly process, the first step is the application of solder paste.

· Component Placement: In the traditional PCB assembly process, the next step is to place the components on the board.

· Reflow: In the traditional PCB assembly process, the next step is reflow, which is when the solder is first melted and then resolidified.

· Inspection: The next step in the traditional PCB assembly process is a visual inspection of the board, soldering, and components.

· Through-Hole Part Insertion: The traditional process requires that through-hole insertion be done manually, after the reflow and inspection process.

5. What are the differences of PCBA(SMT) and SMD?

SMT stands for Surface Mount Technology, the entire technology of mounting and soldering electronic components, such as resistors, capacitors, transistors, integrated circuits, onto a printed circuit board or PCB. The components used are also referred to as surface-mount devices. It should be noted that SMT does not need to reserve corresponding through holes for component pins, and SMD is much smaller than through-hole insertion technology.

Features of PCBA:

· Components have no leads or only short leads

· The main body of the component and the solder joint are on the same side of the PCB

Features of SMD:

· Miniaturization

· No lead (flat or short lead)

· Suitable for surface assembly on PCB

Industry Category