5 Types of Pogo Pin PCB Testing for PCB Manufacturing Process

By:PCBBUY 11/03/2021 09:35

Like most other components are Pogo Pins heat resistant only up to a certain point. Standard housing materials and spring materials may not be able to withstand the heat or can only go once through the reflow soldering process. If you plan to do several sessions, let us know! We will choose the right pins and the right materials for your requirements to avoid male function at a later stage.

Are you interested in Pogo Pin PCB? If you are interested in Pogo Pin PCB, you can check and read the content for more information.

1. What are the advantages of Pogo Pin connector in PCB?

In a design where every bit of space and cost counts, replacing this programming connection with a group of exposed copper pads could make a significant difference. Tag-Connect has done an excellent job of developing a product that does just that: by replacing JTAG and other common programming connections with a small pattern of exposed, circular copper pads that interface with pogo pins (spring-loaded contacts that you can hold in place manually, or clip on if the connection supports it). There are other brands of cables that have built-in pogo pins but the general concept here is to convert bulky header-based connections to smaller, zero-profile connections that free up board space and cost.

2. Why is Pogo Pin PCB testing important?

It’s common to incorporate these on a test or debug PCB that might be utilized during a design or production process, typically if you want to run a functional test or probe a group of signals accessed by small exposed copper pads. These pads can be very close together and occupy minimum board space, a great way to save real estate in a space-conscious design. In order to better manage temporary, external connections by saving cost and board space, and creating a quicker, more reliable means to test or debug a PCB, consider adding pogo-pin-based connections to your design today.

3. How to use Pogo Pin connectors in PCBA?

Like most other components are Pogo Pins heat resistant only up to a certain point. Standard housing materials and spring materials may not be able to withstand the heat or can only go once through the reflow soldering process. If you plan to do several sessions, let us know! We will choose the right pins and the right materials for your requirements to avoid male function at a later stage.

4. What is the working principle of Pogo Pin PCB?

This article will look at:

· The basic structure of a spring-loaded connector

· Which kind of inner structure fits which application

· The electrical performance of pogo pins

· The durability of pogo pins

· The basic structure of a pogo pin.

A generic pogo pin consists of 3 parts: Barrel, Plunger, and Spring. Pogo pins are often inserted into housing for better stability, but in many cases, those pins are just soldered directly onto a PCB.

5. How to use Pogo Pin PCB correctly?

Electrical Connection

While you can solder directly to pogo pins, they are wear items and easily bent or broken, so serious production fixtures tend to use pogo pin sockets in which the pins are replaceable. These can often most easily be sourced by doing a search on the part number, for example a P75 pogo uses an R75 socket. There are at least two types of sockets - solder tail, and what is basically a wire wrap post (or if spaced in the right array, possibly a header pin). Pogo sockets have a ridge on them and so need to be inserted into whatever holds them from the pin side - which means that if you pre-wire them you need to thread the wire through the hole and then insert the socket, so you have to do that before putting a connector on the far end of your wire or combining it into a bundle. You can typically make the solder joint small enough, thread the holder through the fixture, and then put a piece of heat shrink over the joint; you can also buy sockets prewired to lengths of wire.

Mechanical Mounting

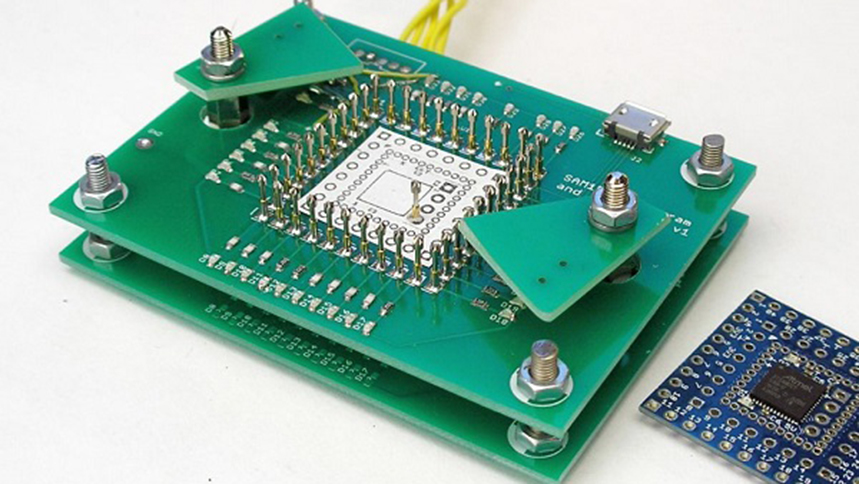

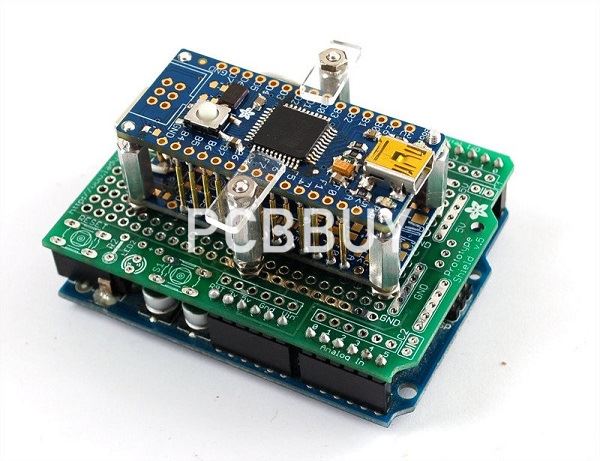

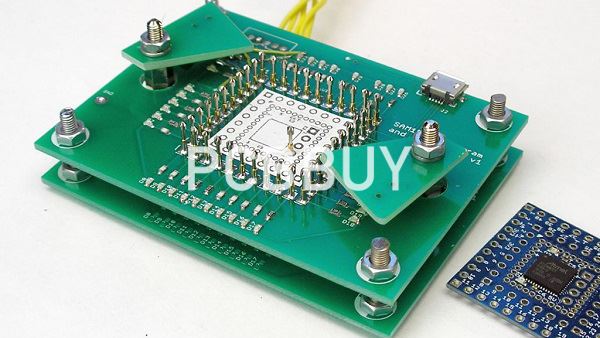

Production fixture traditionally use holes CNC drilled in a piece of acrylic or similar plastic. If you don't have ready access to that capability, two viable alternatives are using a common thermoplastic filament 3d printer (in which case you will almost certainly have to ream the holes to size afterwards) or using a stack of multiple purpose-made PC boards. If you go with multiple boards, consider putting a spacer in between so you increase the vertical distance over which you are fixturing the pins (essentially, treat a 3-piece prototype PCB fab as a CNC machining service that EE's are already familiar with sending jobs to, with the added benefit that you can have traces from the pogo plated through holes to a connector which you install on one board in the stack to bring off your wiring harness)

Actuation

Far east factories operating in a semi-manual mode seem to fixtures where the pogos in their carrier are lowered from above via linear bearings riding on rails and actuated by a toggle clamp of the sort you might see on shop cart casters. In contrast, small batch US makers tend to have the pogos sticking up from a fixture with some alignment pins over which the board is held, possibly secured by a toggle clamp.

For small numbers of pins as you show you can also make up a simple cable ending in a head with a few pins in it, and hold that in place during a brief flashing operation (but such solution probably won't support enough signals for a full test, only programming and say serial output). Tag Connect offers a pre-made form of this for a few pin counts and spacings, the idea being that you design the board to their pogo head rather than designing a custom pogo fixture for your board.

Industry Category