How to Check Quality of PCB? & 5 tips of AOI Inspection Process

By:PCBBUY 09/17/2021 09:53

Automated optical inspection (AOI) is a machine-based technique used to test and check PCB for potential errors, such as surface defects, dimensional defects, as well as component placement defects. As the circuit board is more and more complicated, it’s hard and impossible to manually check the boards, needless to say, AOI plays an important role in checking the printed circuit board after assembly.

What’s more, it does make a great effect on getting the necessary product quality in the production line with low cost. In this passage, we will provide you 5 tips of AOI inspection. And if you are curious about the quality checking of PCB manufacturing, please read the content below for more.

What are the 5 tips about AOI to check the PCB quality?

1. Know advantages of AOI?

Positional accuracy

AOI system should have sub-pixel accuracy as a rule-of-thumb, which make sure the there is enough accurate for the system to detect the small deviations in position that can result in a 01005 defect.

Low cost

AOI test can improve the pass rate of PCB so that reduce the PCB cost.

Multiple inspection objects

AOI test not only works well used in PCBs, but also for PCB assembly. As to PCB, it checks the defects, for example, shorts, opens and insufficient solder.

Network capable software

One important function of any AOI system is data collection and retrieval. The data can be in the form of a text output, image collection, database, or a combination of several formats.

Good Flexibility

AOI can be used in any stage of fabrication process based on the needs and cost tolerance capacity. As well as it can modify immediately the fabrication or assembly parameters to manufacture correctly the subsequent products.

2. Why is AOI so popular?

Printed circuit boards are an integral part of automated optical test inspection. When ordering the board, it should immediately correct its mistake. The financial implications of such things would be disheartening.

As mentioned earlier, due to the increasing complexity of modern circuit boards, manual inspection has become obsolete. Know points to check the circuit board by soldering automation. Contemporary markets now require high volume, top-notch products that can reach their customers as fast as possible without compromising quality inspection.

AOI is a fundamental tool in an electronics test strategy to ensure that faults are detected as fast as possible in production for products to reach the market in the shortest time possible.

3. Notice defects of AOI

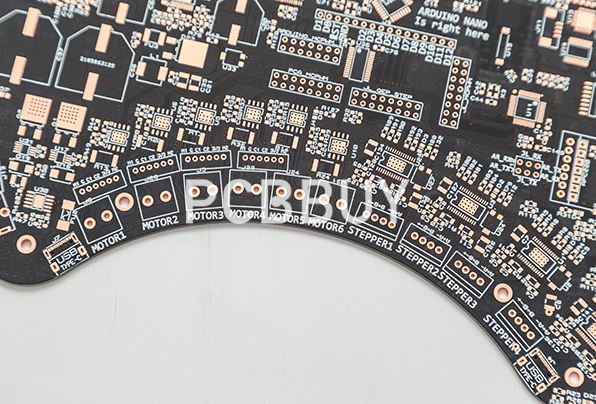

In addition to the defects that can be detected by AOI (inner bare board and outer board), there are two main types of defects in structural loading boards that must be detected during final inspection:

Defects on the surface: discoloration, uneven surface and foreign objects on or in the solder stop paint; Alignment problems of solder stop paint: the liner is over-shielded, the hole or line that should be covered is exposed, the area where the pad or hole should be exposed, and the area that should be protected by complete solder stop paint is incomplete.

4. The typical AOI process

Typical AOI inspection technologies currently used in circuit board manufacturing include: film inspection, drill inspection, hole location inspection, circuit inspection, blind hole inspection, bump inspection, visual inspection, etc.

At present, the most used AOI inspection technology in the circuit board manufacturing industry is the inspection of the appearance of the circuit board. Although the size of the circuit characteristics of the circuit board has been reduced by more than ten times, the optical system and the matching hardware and software systems have also made great progress.

5. AOI camera configuration

The still image-camera system: We need to place it near the target PCB, and its effectiveness depends on the existence of the sound lighting system. The camera might need to be under the control of an audio software system to ensure efficacy.

Streaming Video: This is also another type of camera used for optical inspection. From the streaming video, full-frame shots are taken and subsequently analyzed. Conclusion this approach is not definite as it is not so accurate compared with other alternatives, but it possesses an advantage of speed over others.

Industry Category