6 types of PCB surface finishes & PCB surface finishes comparison

By:PCBBUY 09/10/2021 09:26

PCB surface finishes are intended to protect your board from external harm. Let’s explore the types of PCB surface finishes and see when we should opt for which type. In circuit board manufacturing, the process of implementing the PCB surface finish is critical in enhancing the reliability and shelf life of the PCBA.

Since PCB surface finish is pretty important to PCB manufacturing, we provide you different types of PCB surface finish. And if you are looking for the professional knowledge about this topic, please check and read the content we prepare for more information.

What are the features of PCB surface finishes?

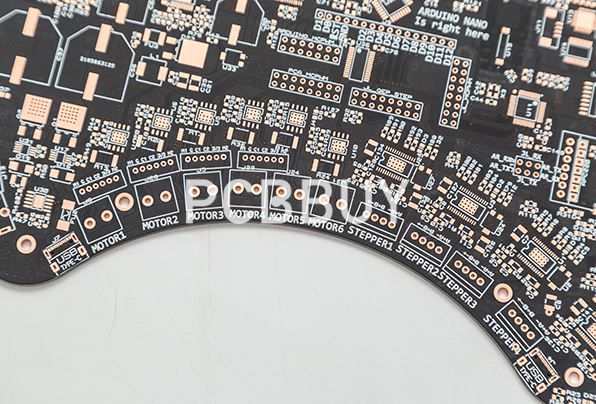

PCBs are made of copper to ensure electric currents flow efficiently. These metals require appropriate protection from the elements to avoid oxidation and other corrosion. A range of finish types provide different levels of protection against deterioration. They also aid in certain use, such as with soldering. Various circuit board finishes are available, from options that are affordable and easy-to-apply to expensive or difficult-to-manage finishes used in only the most advanced applications.

What are the considerations about PCB surface finishes?

The PCB surface finish helps protect copper circuitry from corrosion. It also provides a solderable surface for your components. There are a number of factors to consider, including:

· The components you use

· Your expected production volume

· Your requirements for durability

· Environmental impact, and

· Cost

What are the 6 different types of PCB surface finishes?

HASL

It is widely available and very economical. The board is dipped in molten solder and then leveled off with a hot air knife. If you’re using through-hole or larger SMT components, HASL can work well. However, if your board will have SMT components smaller than 0805 or SOIC, it is not ideal. A HASL surface finish offers high-quality solderability and accommodates multiple thermal cycles while also being one of the more affordable options.

HASL finishes are created by dipping the board into a tin and lead or tin and nickel solder and holding it there for some time. Once the PCB is removed, hot bursts of air called air knives remove the excess finish. HASL finishing allows for a large processing window, but various factors can affect its evenness and therefore its solderability.

Lead-free HASL

The Lead Free Version (LFH) of HASL PCB finish became the most frequently considered surface finish next to immersion gold early in the process of safer finish alternatives. So, why didn't lead free HASL become the new standard instead of simply becoming a hassle for manufacturers? Due to the complicated nature of applying a LFH finish, some circuit board manufacturing facilities may need to outsource this process.

ENIG

The ENIG is a common acronym that stands for Electroless Nickel Immersion Gold. As the hot air solder leveling, it is also a surface finish of the printed circuit board industry. The ENIG got its name because it comprises electroless nickel plating, which is coated with a slim layer of immersion gold. This type of finish involves a two-layer metallic coating; it consists of electroless plating that is covered with a thin layer of immersion gold, the function of the immersion gold is to safeguard the nickel from oxidizing during storage, and the nickel functions more like a barrier to the copper and a surface on which the components are soldered.

OSP

An OSP surface finish is an example of an organic PCB finish. There are no toxins involved in the process, making it environmentally friendly while still retaining its protective and anti-corrosive properties. Because of the absence of harmful chemicals, OSP boards are also RoHS compliant. This water-based finish provides a flat surface for attaching additional PCB components, and like the HASL process, it is cost-effective.

Immersion Tin

Immersion Tin is the least expensive of all types of coatings. It is very economical; however, it does come with certain shortcomings. One of the main drawbacks of immersion Tin is, once you deposit the tin onto copper, it will begin to tarnish. This also means if you wish to avoid low quality solder joints, it is imperative to do your soldering activity within 30 days.

Immersion silver

Immersion silver is a RoHS compliant finish available on any PCB configuration, at no additional cost. Immersion silver is less expensive than Electroless-Nickel Immersion Gold (ENIG); safer than immersion tin (for the environment); easier to use than Organic Solder Preservative (OSP); has a more level (planar) surface than hot air surface leveling (HASL); well suited to lead-free assembly techniques

Industry Category