All Basics of PCB Schematic Design Tutorial

By:PCBBUY 06/24/2022 09:59

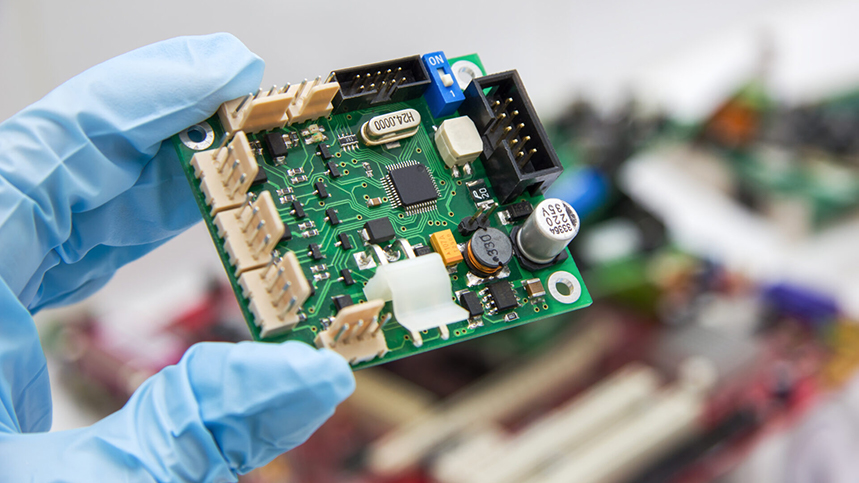

Once you are working in your schematic capture system, there are some things that you can do to make sure that the design that you are creating will result in an easily assembled board: if you are curious about the PCB schematic design, please check and read the con tent below for more information.

What are the errors during PCB schematic design?

It is very important to ensure that any schematic that has been captured is fully checked. While the simulation and other applications now available as part of an end-to-end design suite will trap and highlight many errors, some can still get through. Errors that creep through can be quite subtle. One that has been seen is where a particular node may be given slightly different names on different sheets.

As the names are different they will not be connected by the computer. For example a node may be labelled "0v" on one sheet, but could appear as "gnd" on another. Accordingly it is very important to ensure that errors such as these do not creep through. Discipline in naming is essential.

Computer based schematic capture has greatly simplified the process of drawing circuit diagrams. Circuit schematics can be drawn as the circuit is designed, and managed in such a way that there is little room for error. While errors can occur, the level of errors has fallen dramatically with the introduction of circuit schematic capture software.

What information is needed for PCB schematic design?

Contained within the schematic database is a lot of precise information that the PCB design CAD system needs in order to do its job. If you were able to peel back the cover of an electronic schematic, here is some of what you would find buried inside:

Component data: Each symbol on a schematic is the logical representation of an actual physical component that will eventually be assembled to the circuit board. As such, these symbols, or components, need to contain part numbers, values, tolerances, and other important data that will be reported to the bill of materials. Some of the CAD components will be composed of either multiple symbols, or multiple instances of the same symbol, and those associations have to be managed. For like pins and gates in a component that can be swapped electrically, that information also has to be managed as well. In addition, schematic components will need their associated PCB footprint and SPICE model information for layout and circuit simulation.

Connectivity data: Most of the component pins will be connected to other pins in the design, and that information makes up the connectivity portion of the database. Some pins will be connected to global power and ground nets, while most of the pins will be connected as individual nets. These nets can be grouped together in busses to clarify their intent for the circuit board layout designers, which is helpful when dealing with large groups of memory of data connections. For those pins that aren’t connected, they will sometimes be flagged as a “non-connected pin” in order to satisfy the connection requirements of the schematic design rules.

Design rules: Non-connected pins are only one of the design rules that can be specified in the schematic database. Electrical requirements can be added to nets to ensure that they are designed with the proper length or routing topologies in the PCB layout. In many tools, the actual physical constraints such as trace width and spacing can be specified as well in the schematic. This gives the PCB designer more control over how the circuitry will be physically laid out. There are also many other schematic constraints that can be added such as connectivity rules to determine if the nets are connected to the correct pins.

What are the considerations of PCB schematic design?

Once you are working in your schematic capture system, there are some things that you can do to make sure that the design that you are creating will result in an easily assembled board:

Start with your manufacturer

There are a lot of ways that a circuit board can be built, and manufacturing times and prices can vary greatly depending on the processes and materials that are required. Many designs have been canceled because once they reached the manufacturer, the fabrication and assembly costs were so high or lead times were so lengthy that the board wasn’t affordable. To avoid this problem, work upfront with your vendors to make sure that you are designing a board that can be built within your time and cost budgets.

Use approved components

Another important consideration is the components that you will be using on the board. We’ve already talked about making sure that you are using approved parts in order to get the design right, but it goes further than that. You also need to make sure that the parts you are using are going to be available for the life cycle of the design, and their cost is within your budget. The last thing you need in the middle of building the board is to find out that a critical part is no longer available or is too expensive, requiring you to redesign the board.

Make sure that the schematic and layout match

All too often, the final layout of the board doesn’t match the schematic which leads to bad board builds. Problems like these can usually be traced back to a schematic change that was not incorporated into the board layout, or changes on the layout that weren’t back annotated into the schematic. Make sure that before you release the design for manufacturing that the schematic and layout are both finalized and updated, and then synchronized together. This way you will make sure that the schematic, bill of materials, and the layout all match together.

Industry Category