Aspect Ratio Stencil in SMT Printing and Its Impact on Solder Quality

By:PCBBUY 10/29/2025 17:16

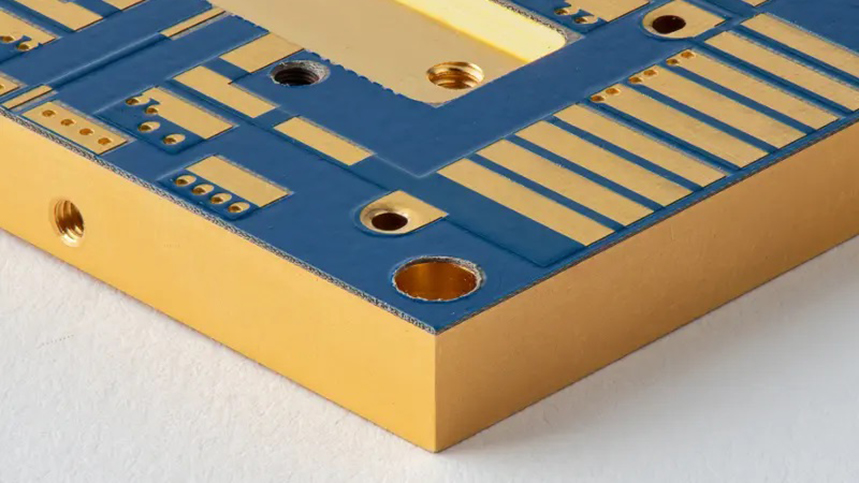

Application Solder paste printing in surface-mount technology (SMT) assembly is among the most crucial processes in a PCBA that defines the end-result features in terms of quality and reliability. This process is very sensitive to the design and performance of the aspect ratio stencil. This is an aspect that determines the efficiency of the release of solder paste along stencil apertures and onto PCB pads. In PCBBUY, it is an engineering norm to optimize the aspect ratio of stencils in order to achieve consistent, stable and high yield results of SMT assembly.

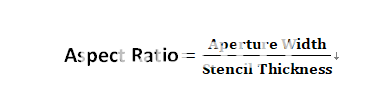

What Is an Aspect Ratio Stencil?

A stencil is a thin metal sheet used to apply solder paste onto PCB pads before component placement. The aspect ratio stencil refers to the ratio between the aperture width and the stencil thickness:

When the aspect ratio is not properly controlled, solder paste may not fully release from the apertures, causing PCB print defects that travel down the process chain and affect reflow solder quality.

Why the Aspect Ratio Stencil Matters in PCBA Manufacturing

The aspect ratio directly affects:

|

Performance Factor |

Influence on Solder Quality |

|

Paste Release Efficiency |

Smooth paste transfer vs. incomplete printing |

|

Print Definition |

Sharp-edged paste prints vs. smeared edges |

|

Defect Risk |

Lower bridging, tombstoning, and insufficient solder |

If the aspect ratio stencil is too low, solder paste tends to stick inside the aperture instead of transferring to the PCB pad. This leads to insufficient solder volume, weak solder joints, or collapse during reflow. Conversely, a well-optimized stencil ratio ensures repeatability, accuracy, and improved long-term reliability.

Industry Standards for Aspect Ratio Stencil Design

The commonly accepted guideline is that the aspect ratio should be greater than 1.5, especially when manufacturing fine-pitch and micro-component assemblies. IPC-7525 stencil design standards also recommend adjusting stencil thickness depending on component type and pad size.

Additional factors affecting stencil performance include:

-

Material type: Stainless steel or nano-coated metal

-

Surface finish: Polished vs. laser-cut edges

-

Stencil thickness: Standard ranges 0.10mm to 0.18mm

How PCBBUY Optimizes Aspect Ratio Stencil for Precision SMT

PCBBUY performs engineering analysis on every SMT job before production. This includes:

1. DFM (Design for Manufacturability) Review

Our engineers evaluate pad sizes, solder coverage needs, and the optimal stencil thickness for each board.

2. High-Precision Laser-Cut Stencils

We use advanced fiber laser systems to create clean, uniform aperture edges for improved paste release.

3. Multiple Stencil Thickness Options

To match different pad geometries:

|

Stencil Thickness (mm) |

Usage Scenario |

|

0.10 mm |

Fine-pitch CSP / 01005 components |

|

0.12 mm |

QFN / micro-BGA applications |

|

0.15 mm |

General SMT assembly |

|

0.18 mm |

Large pads / connectors |

4. Nano-Coating for Micro-Apertures

A hydrophobic coating improves solder paste release in BGA, CSP, and QFN pads.

5. Step Stencil Fabrication

Used when high-density and large components exist on the same PCB.

Case Example: High-Density Microelectronics Assembly

A new project entailed the creation of a small IoT control board with 0.40mm pitch QFN and 01005 resistors. With a 0.10mm aspect ratio stencil, nano-coated apertures, PCBBUY was able to increase the efficiency of transferring paste and decreased under-printing defects by more than 30 percent, leading to an increase in the first-pass yield at reflow inspection.

Quality Control Measures at PCBBUY

To reinforce stable solder performance, PCBBUY employs:

-

3D SPI (Solder Paste Inspection) to verify volume and shape

-

Automated Optical Inspection (AOI) post reflow

-

X-ray inspection for BGA solder joint integrity

-

Full production traceability for every order batch

These checks ensure the stencil performs as expected and that the solder distribution meets IPC standards.

Why Choose PCBBUY for High-Precision SMT Assembly

-

Over 15 years of PCB + PCBA manufacturing experience

-

Professional DFM consulting on each order

-

Certified material sourcing and process control

-

Capable of handling ultra-fine pitch and advanced packaging components

PCBBUY is trusted for industries requiring precision PCBA—including medical electronics, automotive systems, consumer electronics, and industrial automation.

Conclusion

A properly optimized aspect ratio stencil is the foundation of accurate solder paste printing and high-quality SMT assembly. Through professional stencil engineering and manufacturing expertise, PCBBUY ensures reliable and efficient assembly results, whether for prototype runs or high-volume production.

FAQ About Aspect Ratio Stencil

Q1: What aspect ratio is recommended for stable solder paste release?

Generally, an aspect ratio of greater than 1.5 ensures smoother paste transfer.

Q2: Can PCBBUY design a stencil based on my PCB Gerber files?

Yes. PCBBUY performs full DFM review and will recommend the ideal stencil thickness and aperture adjustments.

Q3: Does PCBBUY offer step stencil fabrication?

Yes, we support step-up and step-down stencils for mixed component height assemblies.

Industry Category