Automotive PCB design guidelines

By:PCBBUY 08/07/2021 17:33

To achieve the smart operational requirements of advanced automotive systems necessitates following specific essential automotive PCB design guidelines. These guidelines can be best understood by first exploring the challenges of designing boards for these vehicles. In this article, we will focus the features of automotive PCB, please check the content we prepare to learn more information about it.

What are the performances attributes of automotive PCB?

• Multiple categories of automotive PCBs

Automobiles combine machinery and electronic equipment. Modern automobile technology integrates traditional technique and advancing scientific technology, such as manual inner decorating parts and advancing GPS. In modern automobiles, there is electronic equipment with different functions at different positions and different functions derive from different types of PCBs.

According to substrate materials, automotive PCBs can be classified into two main categories: inorganic ceramic-based PCB and organic resin-based PCB. Ceramic-based PCB features high temperature resistance and excellent size stability, making it directly applied in motor system with high temperature. However, it features bad ceramic manufacturability and high cost. At present, with the development of resin substrate material in terms of its heat resistance capability, resin-based PCB has been widely applied in automobiles with substrate material with different performances applied in different positions.

Generally speaking, Flexible multilayer PCBs and Rigid PCBs are applied in normal gauges indicating vehicle speed and mileage and air conditioner equipment. Double-layer or multi-layer PCBs and Flex PCBs are used in audio and video entertainment equipment inside automobiles. For communication and wireless positioning equipment and security control equipment, multi-layer PCBs, HDI printed circuit boards and Flex PCBs are applied.

• Different reliability requirements for PCBs at different positions

Concerned with public security, automobiles belong to high-reliability product category, so automotive PCBs have to pass some reliability tests apart from ordinary requirements such as dimension, size, mechanical and electric performance.

a. Thermal Cycling Test (TCT)

Five grades classified according to different positions of automobiles.

b. Thermal shock test

Automotive PCBs are more applied in the environment with high temperature, which is especially true for Thick Copper PCBs that have to deal with external heat and self-producing heat. As a result, automotive PCBs have a higher requirement on heat resistance.

c. Temperature humidity Bias (THB) test

Because automotive PCBs stay in multiple environments, including rainy day or humid environment, it's quite necessary to implement THB test for them. The test condition includes the following elements: temperature (85°C), humidity (85%RH) and bias (DC 24V, 50V, 250V or 500V). THB test has to consider CAF migration of PCBs. CAF usually takes place between adjacent vias, via and line, adjacent lines or adjacent layers, leading to insulation reduction or even short circuit. Corresponding insulation resistance depends on distance between vias, lines and layers.

What are the characteristics during automotive PCB design?

• High-frequency substrate board

Automotive collision-resistance/predictive braking safety system plays a role as a military radar device. Since automotive PCBs are responsible for transmitting microwave high-frequency signals, substrate with low dielectric loss needs to be applied with the ordinary substrate material to be PTFE. Different from FR4 material, PTFE or similar high-frequency substrate materials require special drilling speed and feeding speed during drilling.

• Thick copper PCB

Automotive electronics brings more heat energy owing to high density and power and hybrid power and electromotives tend to require more advancing electric power transmission system and more electronic functions, which leads to more requirements on heat dissipation and large current.

It's relatively easy to fabricate thick copper double-layer PCBs while it's much more difficult to fabricate thick copper multi-layer PCBs. The key point lies in thick copper image etching and thickness vacant filling.

Inner routes of thick copper multi-layer PCB are all thick copper and therefore and graphic transfer photo-induced dry film is also relatively thick, requiring extremely tremendous etch resistance. Thick copper graphic etching time will be long and etching equipment and technical condition in the best state so as to ensure complete routings of thick copper.

Surface difference is relatively large between inner conductor of thick copper multi-layer PCB and insulating substrate material and ordinary multi-layer board lamination fails to totally fill resin with cavity generated. In order to solve this problem, thin prepreg with a high content of resin should be applied as much as possible. Copper thickness of inner routings on some multi-layer PCBs is ununiform and different prepregs can be applied in areas with a large thick copper difference or a small difference.

• Component embedment

Component embedded PCBs were massively applied in mobile phones in order to increase assembly density and decrease component size, which is acquired by other electronic equipment as well. Therefore, component embedded PCBs are also applied in automotive electronic equipment.

According to different component embedment methods, there are numerous manufacturing methods for component embedded PCBs. Component embedded PCBs for automotive electronics have mainly 4 manufacturing methods

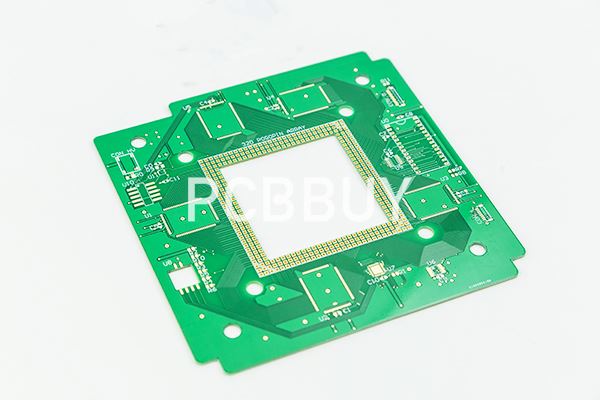

• HDI technology

One of the key functions for automotive electronics lies in entertainment and communication among which smart phones and tablet PCs require HDI PCBs. Thus, technologies contained in HDI PCBs such as micro via drilling & plating and lamination positioning are applied in automotive PCB manufacturing.

Industry Category