Bare Board Testing: Ensuring PCB Quality Before Assembly

By:PCBBUY 12/31/2025 15:38

In PCB manufacturing, quality issues discovered after assembly often lead to high rework costs and production delays. For this reason, bare board testing plays a critical role in ensuring PCB quality before components are assembled.

By verifying electrical connectivity at an early stage, manufacturers can prevent downstream failures and deliver more reliable products to customers.

What Is Bare Board Testing?

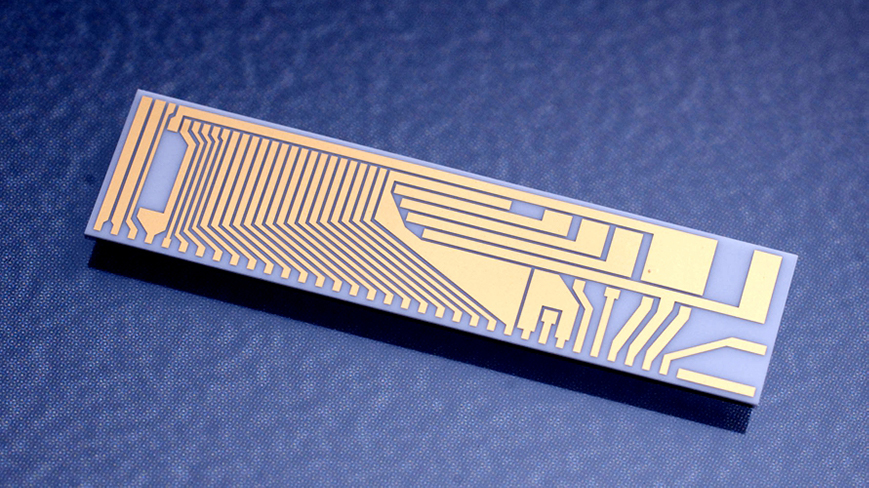

Bare board testing refers to the electrical testing of a printed circuit board before any components are mounted.

At this stage, the PCB contains only copper traces, vias, and pads. The primary purpose of bare board testing is to verify that the fabricated PCB matches the intended electrical design and contains no connectivity defects.

Where Bare Board Testing Fits in PCB Manufacturing?

Bare board testing is typically performed after PCB fabrication and surface finishing, but before shipment or assembly.

It acts as a final verification step to confirm that the board is electrically sound.

This step is especially important for multilayer, fine-pitch, and high-density PCB designs.

Common Bare Board Testing Methods

Electrical Test (E-Test)

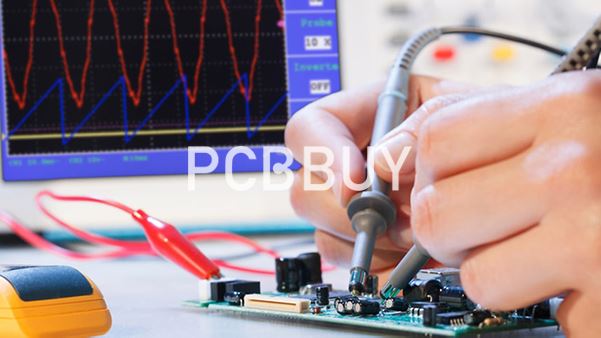

Electrical testing, often called E-test, checks for open circuits and short circuits across the PCB.

It compares the fabricated board against the design netlist to ensure correct connectivity.

E-test is a standard quality requirement for most PCB manufacturing projects.

Flying Probe Testing

Flying probe testing uses movable probes instead of dedicated fixtures.

It is well suited for prototypes, low-volume orders, and designs that change frequently.

This method provides flexibility and reduces upfront tooling cost.

Fixture-Based Testing

Fixture-based testing uses custom test fixtures with fixed probes.

It offers faster test speeds and high repeatability, making it ideal for mass production.

The choice between flying probe and fixture testing depends on volume, complexity, and cost considerations.

What Defects Can Bare Board Testing Detect?

Bare board testing can identify a wide range of manufacturing defects, including:

-

Open circuits

-

Short circuits

-

Incorrect net connections

-

Fabrication-related connectivity errors

Detecting these issues before assembly prevents costly failures later in the production process.

Why Bare Board Testing Is Critical for Export PCB Quality?

For export-oriented PCB manufacturing, consistent quality is essential. Bare board testing helps ensure that only electrically verified PCBs move forward to assembly or shipment.

This reduces customer complaints, improves reliability, and supports long-term product performance.

Manufacturing Challenges in Bare Board Testing

As PCB designs become more advanced, bare board testing also becomes more challenging.

Common difficulties include:

-

Fine-pitch traces and small pad sizes

-

High layer count and dense via structures

-

Increased test point complexity

-

Balancing test coverage with production efficiency

Effective testing requires both suitable equipment and engineering expertise.

How Manufacturing Capability Supports Reliable Bare Board Testing?

Test Equipment and Method Selection

Choosing the appropriate testing method ensures adequate coverage without unnecessary cost. Manufacturing experience helps determine when flying probe or fixture testing is most effective.

Netlist Verification and Test Programming

Accurate netlist data is essential for meaningful test results. Engineering teams prepare and verify test programs to ensure correct comparison with the design intent.

Integration with Quality Control Processes

Bare board testing is most effective when integrated into a broader quality management system. Test results help identify process trends and improve overall manufacturing stability.

PCBBUY’s Approach to Bare Board Testing

PCBBUY treats bare board testing as a core element of PCB quality assurance. By combining appropriate test methods with structured engineering review, PCBBUY ensures that electrical defects are identified before boards reach the assembly stage.

Key capabilities include:

-

Standard electrical testing for PCB orders

-

Support for both prototype and volume production

-

Testing aligned with export-quality standards

-

Engineering-driven quality control processes

This approach helps reduce risk and deliver consistent PCB quality to global customers.

Bare Board Testing vs Assembly-Level Testing

Bare board testing focuses on PCB connectivity, while assembly-level testing verifies component placement and solder integrity. Both are important, but bare board testing cannot be replaced by post-assembly inspection. Testing the PCB first ensures that assembly resources are not wasted on defective boards.

How Customers Can Specify Bare Board Testing Requirements?

Customers can improve quality outcomes by:

-

Requesting electrical testing in fabrication requirements

-

Providing accurate netlists and design data

-

Discussing test coverage expectations with the manufacturer

Clear communication helps align testing strategy with project goals.

Conclusion

Bare board testing is a critical step in modern PCB manufacturing, ensuring electrical integrity before assembly begins. As PCB designs continue to grow in complexity, effective testing depends on both suitable equipment and manufacturing expertise.

By integrating bare board testing into a structured quality control system, PCBBUY helps customers achieve reliable PCB production and reduce overall manufacturing risk.

FAQ

What is bare board testing?

Bare board testing is the electrical testing of a PCB before component assembly to verify correct electrical connectivity and detect opens or shorts.

Why is bare board testing important in PCB manufacturing?

It helps identify electrical defects early, reducing assembly failures, rework cost, and delivery delays.

What defects can bare board testing detect?

Bare board testing can detect open circuits, short circuits, and incorrect net connections caused by fabrication errors.

What is the difference between flying probe and fixture-based testing?

Flying probe testing is flexible and ideal for prototypes or low volumes, while fixture-based testing is faster and better suited for mass production.

Does PCBBUY perform bare board testing on all PCBs?

PCBBUY provides electrical testing as part of its quality control process, with testing methods selected based on project requirements.

Can bare board testing replace assembly testing?

No. Bare board testing ensures PCB connectivity, while assembly testing verifies component placement and solder quality. Both are necessary for full product reliability.

Industry Category