Check the number of flying needles on the circuit board

By:PCBBUY 12/15/2023 09:18

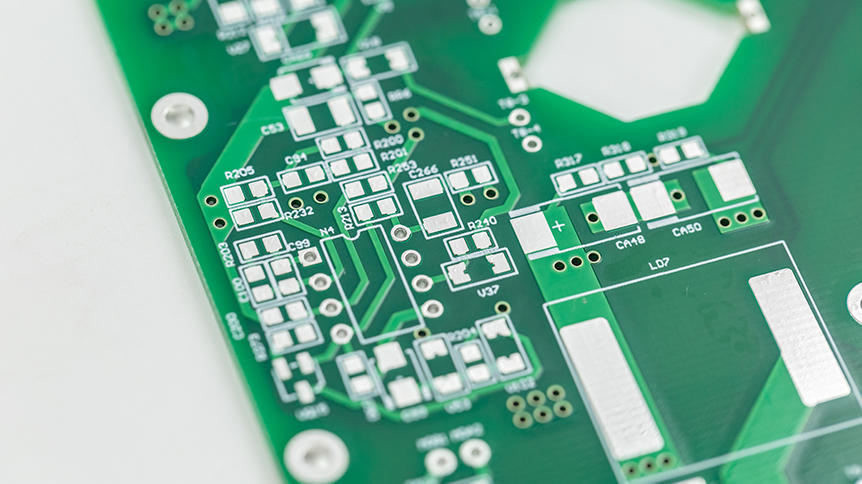

In the electronics industry, flying probe testing is a method used to inspect the connectivity and electrical performance of circuit boards. This test simulates signal transmission under actual operating conditions to ascertain proper connections and adherence to electrical specifications. During flying probe testing, the use of a point count is necessary to label and manage connection points on the circuit board.

I. Concept of Point Count:

The point count refers to the quantity of connection points on the circuit board, used in flying probe testing to simulate signal transmission conditions. A higher point count ensures a more comprehensive assessment of the circuit board's connectivity and electrical performance.

II. Determining the Point Count:

Several factors contribute to determining the point count:

Complexity of the Circuit Board: Higher complexity requires more probe points. For instance, intricate digital circuit boards demand a greater number of probe points for assessing their connectivity and electrical performance.

Testing Requirements: Varying testing needs dictate different point counts. For a comprehensive assessment, more probe points are necessary to simulate actual signal transmission conditions.

Cost Consideration: Determining the point count should consider cost factors. Excessive probe points increase testing expenses, necessitating a balanced approach to ensure quality testing within budget.

III. Numbering and Management of Probe Points:

During flying probe testing, systematic numbering and management of connection points are crucial for accuracy and repeatability. Typically, probe points can be labeled using the following methods:

Coordinate Labeling: Numbering based on the coordinates of connection points, utilizing alphanumeric characters to denote their positions. This method suits regularly arranged connection points.

Pin Labeling: Numbering based on pin designations of connection points, using pin numbers to indicate their locations. It's suitable for connection points with standard packaging and pin designations.

Functional Labeling: Numbering based on the functionality of connection points, utilizing functional names or codes to represent their positions. It's applicable for connection points with specific functionalities.

After determining the probe point numbering method, establishing a corresponding management system is essential to ensure test data accuracy and traceability. Flying probe test data generally falls into these categories:

Connectivity Test Data: Includes electrical parameters like resistance, capacitance, inductance, etc., to assess the conductive properties and transmission characteristics of connection points.

Functional Test Data: Encompasses signal waveforms, timing, etc., to evaluate the proper functioning of connection points.

Fault Localization Data: Contains information about the location and type of faulty connection points, aiding in their identification and repair.

By employing a systematic approach to numbering and managing probe points, the efficiency and accuracy of flying probe testing can be significantly enhanced, ensuring that the circuit board's connectivity and electrical performance meet the required standards.

Industry Category