Choosing the Right SMT PCB Assembly Supplier – Why PCBBUY Delivers Reliable Results

By:PCBBUY 09/16/2025 17:01

Why the Choice of an SMT PCB Assembly Supplier Matters

When developing a new electronic product, many companies face the same question: which SMT PCB assembly supplier should I trust? The answer is not only about price but also about quality, consistency, and speed to market.

A reliable supplier ensures that every PCB performs exactly as designed, whether it goes into consumer gadgets, industrial machines, or safety-critical automotive modules. This is why many international clients today are seeking partners in China, where strong manufacturing capability meets competitive cost. Among these, PCBBUY has positioned itself as one of the best SMT PCB assembly suppliers, offering both precision and global service.

What Makes a Reliable SMT PCB Assembly Supplier

Choosing a supplier requires evaluating several criteria. Below is a breakdown that helps compare options at a glance:

|

Key Factor |

Why It Matters |

PCBBUY’s Strength |

|

Technical Expertise |

Determines ability to handle complex boards |

Over 15 years of SMT & PCB experience |

|

Equipment Capability |

Precision in component placement & soldering |

High-speed SMT lines, supports 0201, BGA, QFN |

|

Quality Control |

Ensures every board meets international standards |

100% AOI, X-ray inspection, functional testing |

|

Flexibility |

Needed for both prototype and mass production |

One-stop service from samples to high-volume |

|

Global Support |

Smooth communication & logistics |

Multilingual team, worldwide shipping experience |

Many overseas buyers highlight that PCBBUY is not just a China SMT PCB assembly supplier, but also a global partner who understands export requirements and international certification standards.

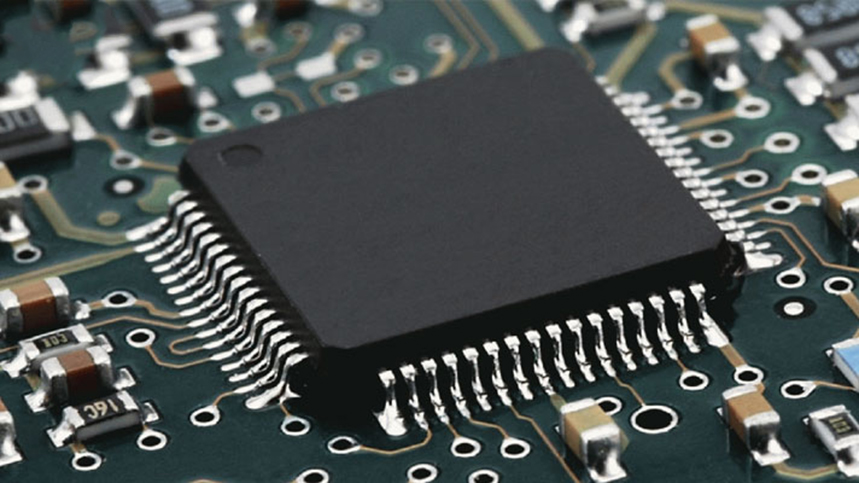

Inside the SMT PCB Assembly Process at PCBBUY

PCBBUY’s assembly line integrates automation with careful human oversight. The process follows these steps:

-

PCB Preparation – Boards are cleaned and visually checked to avoid surface contamination.

-

Solder Paste Printing – Stencils and automated printers apply solder paste with micron-level precision.

-

Pick and Place – High-speed machines mount thousands of components per hour, handling ultra-fine pitch parts.

-

Reflow Soldering – A controlled heating process bonds the components reliably to the PCB pads.

-

Inspection and Testing – AOI detects placement errors, X-ray checks hidden joints like BGAs, and functional testing simulates real-world usage.

-

Final Assembly and Packing – Finished boards are packaged securely for global shipment.

This workflow is not unique to PCBBUY, but what sets them apart is strict process control and the integration of both prototyping and mass production on the same platform.

Why PCBBUY Is Considered a Best SMT PCB Assembly Supplier

Many customers recognize PCBBUY for the following strengths:

-

Advanced Facilities – Capable of handling both simple single-sided SMT boards and complex multilayer assemblies.

-

Diverse Capabilities – Supports SMT, through-hole, mixed assembly, conformal coating, and box-build assembly.

-

Industry Coverage – From telecom equipment and IoT devices to medical electronics and automotive control units.

-

Cost Transparency – Clear quotation system with competitive pricing, especially compared to other SMT PCB assembly suppliers in China.

-

Strong Quality Assurance – Every order is tracked, inspected, and documented before shipping.

Real Example: Automotive Client Success with PCBBUY

One client from Europe in the automotive sector required high-density PCBs with BGA and QFN packages for engine control systems.

-

Challenge: Ensure solder reliability under high heat and vibration.

-

Solution: PCBBUY applied custom reflow profiles, double AOI inspection, and 100% X-ray testing.

-

Result: The PCBs passed automotive reliability testing and were delivered within 14 days.

This case shows why PCBBUY is often chosen as a trusted SMT PCB assembly supplier for high-reliability projects.

How to Select the Best SMT PCB Assembly Supplier for Your Needs

If you are evaluating suppliers, consider the following checklist:

-

✅ Do they hold ISO and IPC certifications?

-

✅ Can they assemble fine-pitch components like BGA or CSP?

-

✅ Do they provide AOI, ICT, and functional testing?

-

✅ Can they support both prototypes and large orders?

-

✅ Do they have international logistics and after-sales support?

PCBBUY meets all of these requirements, making them a reliable choice for both startups and large enterprises.

Conclusion

In the competitive world of electronics, working with the right partner is crucial. A trusted SMT PCB assembly supplier can reduce costs, improve product reliability, and speed up time-to-market.

With advanced production lines, strict quality control, and proven global delivery experience, PCBBUY is more than just a China SMT PCB assembly supplier – it is a long-term partner for success.

📩 Contact PCBBUY today to discuss your SMT PCB assembly needs and get a customized solution for your project.

Industry Category