Common Design Mistakes in 8 Layer PCB

By:PCBBUY 01/29/2026 09:41

Introduction

As electronic products continue to demand higher performance, smaller form factors, and improved signal integrity, 8 layer PCBs have become a common solution in industrial, automotive, communication, and high-speed digital applications.

However, increasing layer count also significantly increases design complexity. Many reliability and yield problems in 8 layer PCB fabrication originate not from manufacturing defects, but from early design mistakes that overlook real manufacturing constraints.

This article reviews the most common design mistakes in 8 layer PCB, explains why they occur, and shows how experienced PCB manufacturers help prevent these issues through DFM expertise and process control.

Why 8 Layer PCB Design Is More Challenging?

Compared to low-layer boards, 8 layer PCBs introduce:

-

Complex stackup structures

-

Tighter registration and drilling tolerances

-

Higher sensitivity to thermal and mechanical stress

-

Stronger coupling between design decisions and fabrication processes

Without proper coordination between design and manufacturing, small design oversights can lead to warpage, delamination, via failure, or low production yield.

Mistake 1: Unbalanced Layer Stackup

One of the most common design mistakes in 8 layer PCB is an unbalanced stackup.

Typical problems include:

-

Asymmetrical copper distribution

-

Uneven dielectric thickness between layers

-

Signal layers concentrated on one side

Consequences:

-

Board warpage during lamination

-

Increased risk of delamination

-

Registration issues between inner layers

Manufacturing perspective:

Professional manufacturers review stackups to ensure mechanical symmetry and copper balance, reducing stress during lamination and thermal cycling.

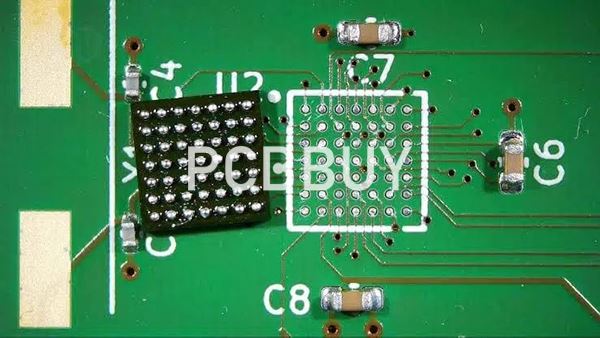

Mistake 2: Incorrect Via Structure Selection

Designers often overuse standard through-hole vias without considering:

-

Aspect ratio limitations

-

Via reliability under thermal stress

-

Signal integrity and routing efficiency

In 8 layer PCBs, poor via choices can cause:

-

Thin or uneven copper plating

-

Via barrel cracking

-

Reduced yield during drilling and plating

Best practice:

Select via structures (through, blind, buried) based on layer usage, thickness, and manufacturing capability, not only routing convenience.

Mistake 3: Inadequate Power and Ground Plane Design

Power and ground planes play a critical role in signal integrity and thermal performance.

Common errors include:

-

Fragmented reference planes

-

Insufficient copper continuity

-

Poor return path planning

Results:

-

Increased EMI

-

Signal noise and impedance instability

-

Localized heating

Manufacturers often identify these issues during DFM review and recommend continuous plane structures and optimized layer pairing.

Mistake 4: Ignoring Copper Balance Across Layers

Large copper areas on some layers and sparse copper on others can disrupt lamination pressure and resin flow.

Potential risks:

-

Inner layer shift

-

Resin starvation or excess resin areas

-

Board thickness inconsistency

Manufacturers mitigate this by:

-

Copper balancing techniques

-

Panel layout optimization

-

Adjusted lamination parameters

Mistake 5: Trace Width and Spacing Below Manufacturing Limits

Designing traces too close to minimum limits may pass CAD rules but fail in real production.

Issues include:

-

Inner layer over-etching

-

Reduced copper thickness

-

Lower electrical reliability

Key insight:

Inner layers experience different etching behavior than outer layers, requiring process-aware trace design.

Mistake 6: Poor Thermal Management Design

8 layer PCBs often handle higher power densities, yet designers may neglect:

-

Thermal vias

-

Heat spreading copper

-

Thermal expansion mismatch

This can result in:

-

Localized overheating

-

Via fatigue

-

Long-term reliability degradation

Manufacturers help by evaluating thermal paths and material selection, especially for high-temperature applications.

Mistake 7: Insufficient Via-to-Plane and Via-to-Edge Clearance

Ignoring IPC recommendations or manufacturing tolerances may cause:

-

Via breakout

-

Shorts between layers

-

Electrical failures after thermal cycling

Accurate clearance design must account for drilling accuracy, layer registration, and plating growth.

Mistake 8: Lack of Assembly Process Consideration

Designs optimized only for fabrication may fail during assembly.

Common oversights:

-

Via-in-pad without proper filling

-

Pads incompatible with lead-free reflow

-

No allowance for multiple reflow cycles

Experienced manufacturers evaluate designs with fabrication and assembly compatibility in mind.

How Manufacturers Help Prevent These Design Mistakes?

Professional PCB manufacturers reduce design risk by offering:

-

Early DFM and stackup consultation

-

Material and process compatibility checks

-

Via and drilling capability alignment

-

Prototyping feedback before mass production

This collaboration significantly improves yield, reliability, and time-to-market.

PCBBUY’s Experience with 8 Layer PCB Manufacturing

With extensive experience in multilayer PCB fabrication, PCBBUY supports complex 8 layer PCB projects through:

-

Optimized stackup and copper balance control

-

Precise drilling and via plating processes

-

Strict lamination and thermal reliability management

-

Comprehensive DFM review before production

These capabilities help customers avoid common design mistakes and achieve stable, repeatable quality.

Conclusion

Designing an 8 layer PCB requires more than routing density and electrical performance considerations.Understanding manufacturing realities is essential to avoid costly failures and delays.

By recognizing common design mistakes in 8 layer PCB and working closely with an experienced manufacturer, designers can significantly improve product reliability and manufacturing success.

FAQ

What are the most common design mistakes in 8 layer PCB?

Unbalanced stackups, poor via selection, inadequate copper balance, and ignoring manufacturing tolerances are among the most common issues.

Why is stackup design critical for 8 layer PCB?

Stackup affects mechanical stability, thermal behavior, signal integrity, and lamination quality. Poor stackup design often leads to warpage or delamination.

Can PCB manufacturers help fix design mistakes?

Yes. Experienced manufacturers provide DFM reviews, stackup optimization, and process-based feedback before production.

How does copper balance affect PCB manufacturing?

Copper imbalance can cause resin flow issues, inner layer shift, and board warpage during lamination.

Why is DFM important for 8 layer PCB projects?

DFM ensures the design aligns with real manufacturing capabilities, improving yield, reliability, and overall production efficiency.

Industry Category