Comprehensive Guide to ENEPIG Plating Specification in PCB Manufacturing

By:PCBBUY 07/29/2025 15:18

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) is a high-performance surface finish solution widely adopted in high-reliability PCB applications. At PCBBUY, we offer highly controlled ENEPIG plating specifications tailored to demanding customer needs. This article explores the technical aspects, manufacturing capabilities, and quality standards behind our ENEPIG processes, helping engineers and procurement teams better understand the advantages and applications of this advanced finish.

What is ENEPIG Plating in PCB Manufacturing?

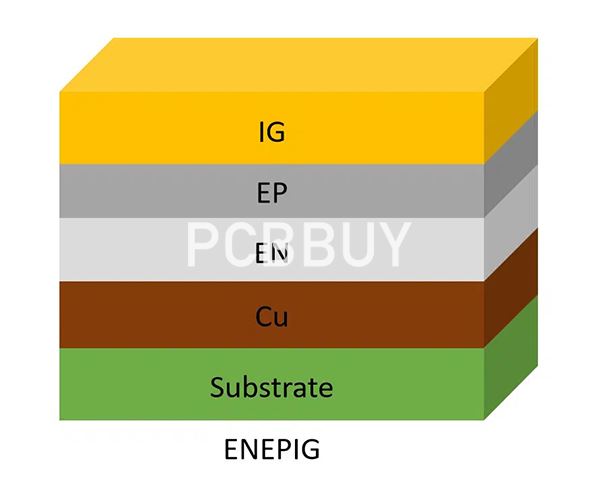

ENEPIG is a three-layer metallic coating applied to copper pads in PCBs. It consists of:

-

A base layer of electroless nickel (Ni),

-

A barrier layer of palladium (Pd),

-

A final immersion gold (Au) layer.

This multilayer PCB structure provides excellent wire bonding compatibility, oxidation resistance, and solderability, making it ideal for BGA pads, fine-pitch components, and IC substrates.

Understanding ENEPIG Plating Specifications at PCBBUY

At PCBBUY, our ENEPIG plating process is tightly controlled with precise thickness specifications and professional-grade quality assurance. The plating PCB stack-up is engineered to meet international IPC standards, while remaining customizable for special engineering requirements.

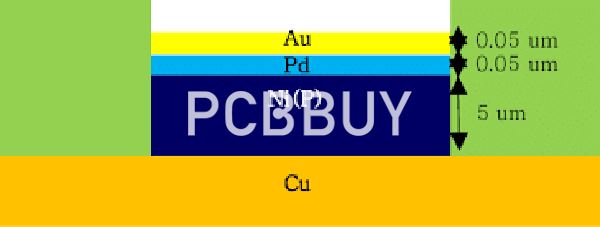

Standard ENEPIG Plating Thickness Specifications

|

Layer |

Thickness Range |

Custom Maximum Limit |

|

Nickel (Ni) |

200μ” |

≤300μ” |

|

Palladium |

1–10μ” |

Pd + Au ≤30μ” |

|

Gold (Au) |

1–10μ” |

Pd + Au ≤30μ” |

-

Tolerance Control: Thickness deviation is maintained within ±10% of the specified target.

-

Special Requirements: Custom stack-ups and tighter tolerances can be evaluated upon request.

The ENEPIG Plating Process at PCBBUY

We utilize a highly automated and stable ENEPIG line powered by reputable chemistry providers. The process includes:

-

Surface Preparation

– Cleaning, micro-etching, and activation of copper pads. -

Electroless Nickel Deposition

– Ni layer at ~200μ” serves as the base for soldering and barrier function. -

Electroless Palladium Deposition

– Pd forms a diffusion barrier to prevent nickel corrosion and enhance wire bondability. -

Immersion Gold Layer

– A thin Au layer offers excellent solderability and oxidation resistance. -

Thickness Testing and Final QC

– In-line XRF and cross-sectional analysis ensure every batch meets the ENEPIG plating specification.

Comparing ENEPIG Plating Specification with Other Surface Finishes

|

Finish Type |

Wire Bondable |

Solderable |

Cost |

Black Pad Risk |

|

ENEPIG |

✅ Yes |

✅ Yes |

$$$ |

❌ Very Low |

|

ENIG |

❌ No |

✅ Yes |

$$ |

⚠️ Medium |

|

OSP |

❌ No |

✅ Yes |

$ |

❌ None |

|

Immersion Ag |

❌ No |

✅ Yes |

$$ |

❌ None |

ENEPIG stands out due to its triple functionality—perfect for designs requiring gold wire bonding and high solder joint integrity.

Applications that Require Precision ENEPIG Plating Specification

-

IC Substrate Boards

-

BGA and CSP Pads

-

High-Frequency RF and Microwave Circuits

-

Medical and Aerospace PCB Assemblies

-

Wire-Bond Applications (Au/Al wires)

Why Choose PCBBUY for ENEPIG Plating Services?

PCBBUY combines cutting-edge facilities, technical engineering teams, and international certification to deliver ENEPIG-finished boards that meet and exceed global standards.

-

✅ Strict compliance with ENEPIG plating specifications

-

✅ Capability to produce custom thickness stacks

-

✅ Real-time X-ray Fluorescence (XRF) testing on every panel

-

✅ Consistent quality for export-grade PCBs

FAQs: ENEPIG Plating Specification at PCBBUY

Q: Can I request a custom Pd:Au ratio?

Yes, as long as the total Pd + Au does not exceed 30μ", we can evaluate and accommodate special stack-ups.

Q: Is your ENEPIG process suitable for aluminum wire bonding?

Yes. Our process ensures proper Pd thickness to support Al wire compatibility.

Q: How do you avoid black pad issues?

We use advanced chemistry with optimized nickel deposition rates and pH controls to eliminate this risk.

Conclusion

By offering precise ENEPIG plating specifications, PCBBUY supports customers across industries requiring high-performance finishes. Whether your need is driven by bonding reliability, corrosion resistance, or RoHS compliance, our ENEPIG line ensures your boards meet the highest quality expectations.

Contact PCBBUY today to get a quotation or technical consultation for your next project with ENEPIG finish.

Industry Category