Copper Plate for PCB Matters for Modern Electronics

By:PCBBUY 11/25/2025 16:04

When we talk about printed circuit boards, most people focus on layers, components, or surface finishes. But one of the most important elements in any PCB is something simple yet powerful: copper. In particular, the term “copper plate for PCB” refers to the copper material that forms the conductive pathways enabling your devices to function smoothly.

Copper is the primary conductive material in printed circuit boards, forming the current-carrying structure of electronic systems. The term “copper plate for PCB” encompasses copper foil, applied copper layers, and copper-based metal substrates used in advanced PCB designs.

In this article, we’ll break down what copper plate means in PCB manufacturing, how it affects performance, and why PCBBUY is trusted by global customers for high-precision copper-based PCBs.

What Is a Copper Plate for PCB?

In PCB manufacturing, “copper plate” usually means one of three things:

-

The copper foil laminated onto PCB substrate

-

The copper thickness (1 oz, 2 oz, 3 oz…) used to build circuits

-

Copper-based metal core boards (copper core PCB)

Regardless of the specific form, copper is the backbone for electrical conductivity, thermal management, and durability.

Types of Copper Plates Used in PCBs

1. Standard Copper Foil

Typical values include:

-

1 oz (35 μm)

-

2 oz (70 μm)

-

3 oz (105 μm)

These are widely used in consumer electronics, communication devices, and everyday industrial boards.

2. Heavy Copper & Ultra-Heavy Copper

For power electronics, PCBBUY provides:

-

6 oz–12 oz heavy copper

-

20 oz ultra-heavy copper (custom order)

These PCBs handle high current, strong thermal loads, and extreme environments.

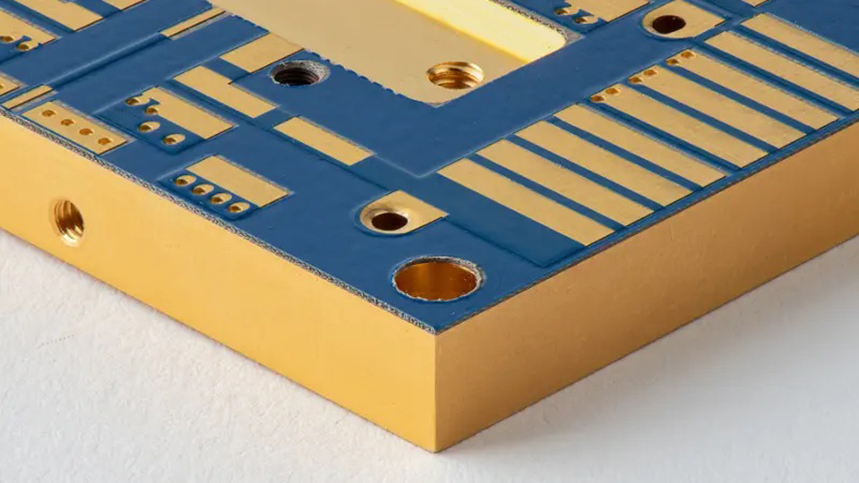

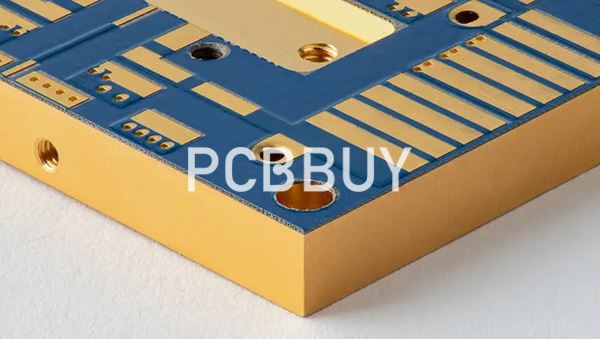

3. Copper-Based Metal Core PCB

Copper-core MCPCBs are known for:

-

Extremely high thermal conductivity

-

Excellent structural strength

-

Application in LEDs, power systems, and automotive electronics

PCBBUY specializes in processing copper-core material, including drilling, plating, and precision routing.

Copper Thickness Fabrication Range

PCBBUY provides:

|

Copper Type |

Thickness |

Notes |

|

Standard Copper |

1–3 oz |

General electronics |

|

Heavy Copper |

6–12 oz |

High-current PCBs |

|

Ultra-Heavy Copper |

Up to 20 oz |

Custom builds |

How Copper Plate Influences PCB Performance?

✔ 1. Electrical Conductivity

More copper means higher current-carrying capability and lower resistance.

✔ 2. Heat Dissipation

Thick copper layers help spread heat efficiently—crucial for power modules or LED systems.

✔ 3. Mechanical Strength

Copper also enhances board rigidity and long-term stability.

PCBBUY’s Capabilities for Copper-Based PCBs

PCBBUY supports a broad range of copper requirements, including:

● Copper Thickness Options

-

Standard 1–3 oz

-

Heavy copper 6–12 oz

-

Ultra-heavy copper up to 20 oz

● Precision Etching

Even with thick copper layers, PCBBUY ensures clean edges, controlled line width, and stable impedance.

● High-Quality Lamination

Copper adhesion is critical; PCBBUY uses high-pressure lamination systems for consistent bonding.

● Metal Core PCB Expertise

For copper-core PCBs, PCBBUY offers:

-

Mechanical milling

-

Deep drilling

-

Specialized via processing

-

High-reliability copper plating

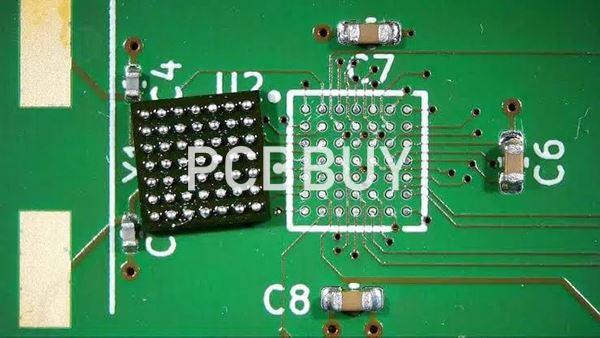

● Strict Quality Control

-

Copper thickness testing

-

Cross-section inspection

-

AOI & E-testing

Every detail is inspected before shipment.

Applications of Copper Plate PCBs

-

High-current power supply boards

-

Industrial control systems

-

LED lighting modules

-

Renewable energy inverters

-

Automotive power electronics

-

High-frequency amplifiers

Why Choose PCBBUY?

Customers around the world choose PCBBUY because:

-

We deliver precise copper thickness control

-

We handle complex heavy-copper designs

-

We offer fast prototyping and mass production

-

We use rigorous QC standards

-

We understand power electronics and thermal challenges

PCBBUY is not just a manufacturer—it’s your global PCB partner.

Conclusion

Copper plate is more than just a metal layer—it’s the core of every reliable PCB. Whether you need standard 1 oz boards or ultra-heavy copper for demanding applications, PCBBUY has the expertise, equipment, and engineering support to bring your ideas to life.

FAQ

1. What does “copper plate for PCB” mean?

It refers to copper foil, copper layers, or copper-core materials used in PCB manufacturing.

2. What copper thickness should I choose?

1–2 oz for consumer products; 3 oz or above for high-current or high-power applications.

3. What is a heavy copper PCB?

A PCB with copper thickness ≥ 3 oz.

4. Can PCBBUY manufacture copper core PCBs?

Yes, PCBBUY specializes in copper-based metal core PCB processing.

5. Does copper thickness affect heat dissipation?

Yes. Thicker copper significantly improves thermal spreading.

6. How does PCBBUY test copper thickness?

We perform cross-section analysis and use professional copper thickness measurement instruments.

Industry Category