Copper Plated PCB Board Simply Guidelines

By:PCBBUY 12/24/2025 14:44

A copper plated PCB board refers to a printed circuit board that has copper deposited onto its surface and through holes using controlled plating processes.

Copper plating is a fundamental step in PCB manufacturing, enabling electrical conductivity, interlayer connections, and mechanical strength. Copper plated PCB boards are widely used in single-layer, double-layer, and multilayer PCB designs across various industries.

Why Copper Plating Is Critical in PCB Manufacturing?

Copper plating plays a key role in PCB performance and reliability:

-

Electrical conductivity: Forms stable signal and power paths

-

Interlayer connection: Creates plated through holes (PTH) and vias

-

Mechanical strength: Reinforces hole walls and copper traces

-

Long-term reliability: Improves resistance to thermal and mechanicalstress

Without reliable copper plating, PCB performance and lifespan can be significantly reduced.

Copper Plating Process for PCB Boards

Electroless Copper Plating

Electroless copper provides an initial thin copper layer on hole walls, allowing subsequent electroplating to build thickness.

Electrolytic Copper Plating

Electroplating increases copper thickness on the PCB surface and inside holes, ensuring sufficient conductivity and durability.

Both processes must be precisely controlled to achieve uniform copper distribution.

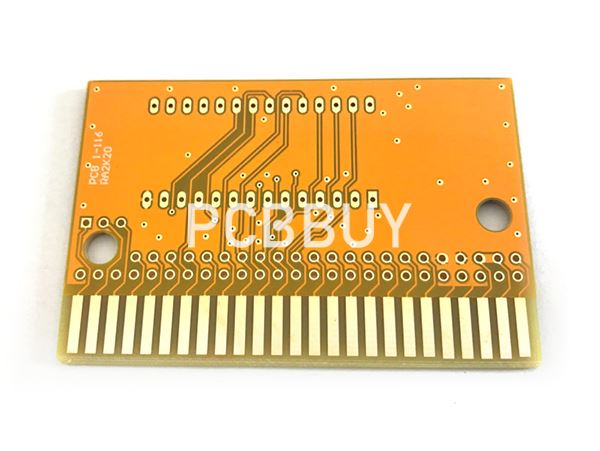

Key Parameters of a Copper Plated PCB Board

Important technical parameters include:

-

Surface copper thickness

-

Plated through hole copper thickness

-

Copper uniformity across the panel

-

Adhesion between copper and substrate

Tight control of these factors is essential for high-reliability PCB applications.

Copper plated PCB boards are commonly used in:

-

Industrial control electronics

-

Automotive electronic systems

-

Power supply and power management boards

-

Communication and consumer electronics

Each application places different requirements on copper thickness and plating quality.

PCBBUY’s Capability in Copper Plated PCB Manufacturing

PCBBUY manufactures copper plated PCB boards using:

-

Stable and mature copper electroplating lines

-

Precise copper thickness control for surface and holes

-

Engineering-driven process optimization

-

Consistent quality from prototype to mass production

PCBBUY supports customized copper plating requirements based on customer design and application needs.

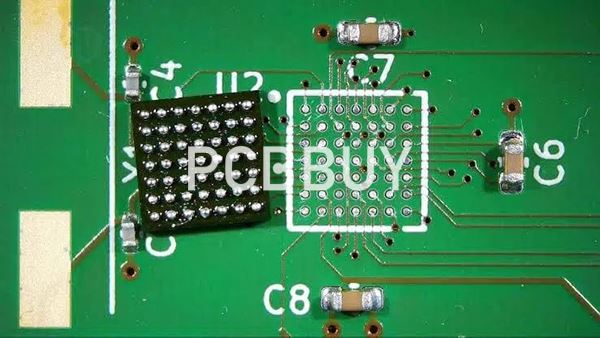

Quality Control for Copper Plated PCB Boards

To ensure consistent quality, PCBBUY performs:

-

Copper thickness measurement

-

Cross-section inspection of plated holes

-

Adhesion and surface quality checks

-

IPC-compliant process monitoring

These measures help ensure that every copper plated PCB board meets reliability expectations.

Design Considerations for Copper Plated PCB Boards

When designing a copper plated PCB board, designers should consider:

-

Required copper thickness for current carrying capability

-

Hole size and aspect ratio limitations

-

Application-specific reliability requirements

PCBBUY’s engineering team can provide DFM support to optimize designs before production.

Conclusion

Copper plating is a foundational process in PCB manufacturing. With controlled plating technology and strong engineering support, PCBBUY delivers reliable copper plated PCB boards for a wide range of applications.

What is a copper plated PCB board?

It is a PCB with copper plated on the surface and inside holes to provide electrical conductivity and interlayer connections.

How thick is copper plating on a PCB?

Copper thickness varies by design and application. Standard and custom copper thickness options are available.

What is the difference between electroless and electroplated copper?

Electroless copper provides the initial conductive layer, while electroplating builds up the required copper thickness.

Where are copper plated PCB boards used?

They are used in industrial, automotive, power, communication, and consumer electronic products.

Can PCBBUY customize copper plating thickness?

Yes. PCBBUY supports customized copper plating thickness based on design requirements and application needs.

Industry Category