Copper Weight in 8 Layer PCB with Design Considerations and Manufacturing Capability

By:PCBBUY 01/16/2026 15:52

Introduction

In multilayer PCB manufacturing, copper weight plays a critical role in determining electrical performance, thermal behavior, and manufacturing complexity. For advanced designs, copper weight in an 8 layer PCB requires careful balance between performance requirements and process capability.

Understanding how copper weight affects manufacturing helps engineers select appropriate stackups and evaluate a PCB supplier’s technical strength.

What Is Copper Weight in PCB Manufacturing?

Copper weight refers to the thickness of copper foil on a PCB layer, commonly expressed in ounces per square foot (oz/ft²). Standard copper weights typically range from 0.5 oz to 2 oz, while heavy copper designs may exceed this range.

In an 8 layer PCB, copper weight may vary between inner layers and outer layers depending on electrical and thermal requirements.

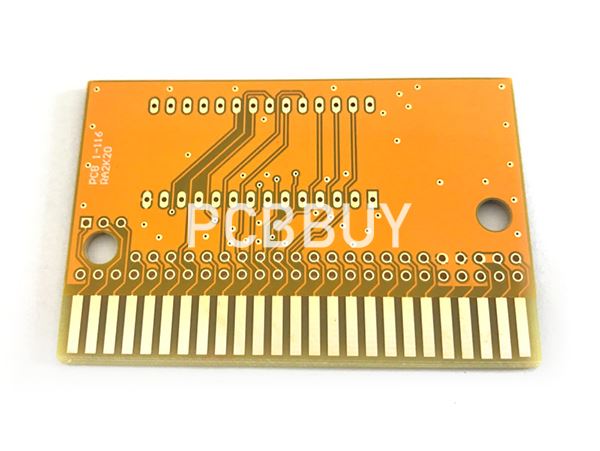

Typical Copper Weight Options for 8 Layer PCB

Most 8 layer PCBs use different copper weights for signal layers and plane layers.

|

Layer Type |

Common Copper Weight |

|

Inner Signal Layers |

0.5 oz – 1 oz |

|

Power / Ground Planes |

1 oz – 2 oz |

|

Outer Layers |

1 oz – 2 oz |

|

Heavy Copper Designs |

≥ 2 oz |

Selecting the correct copper weight is essential for current capacity and manufacturability.

Copper Weight Distribution in 8 Layer PCB Stackup

Balanced copper distribution is important to maintain mechanical stability during lamination.

Unbalanced copper weight can lead to warpage, registration issues, and uneven resin flow.

Proper stackup planning ensures:

-

Symmetrical copper distribution

-

Consistent dielectric spacing

-

Stable lamination results

Manufacturing Challenges Related to Copper Weight

As copper weight increases, manufacturing difficulty rises significantly.

Key challenges include:

-

Harder etching control for thick copper

-

Risk of over-etching fine features

-

Copper thickness uniformity across inner layers

-

Increased stress during multilayer lamination

These challenges are more pronounced in 8 layer PCB structures.

Copper Weight Impact on Lamination and Registration

Heavy copper layers restrict resin flow during lamination, making void prevention more difficult. Higher lamination pressure and precise temperature control are required to ensure reliable bonding. Registration tolerance becomes tighter as copper thickness increases, especially for high-density designs.

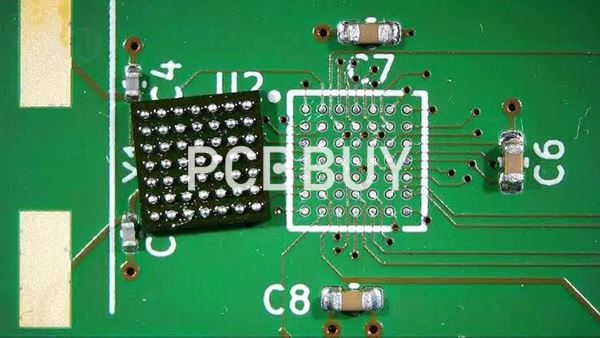

Drilling and Plated Through Hole Considerations

Thicker copper increases drilling complexity and impacts plated through hole quality.

Manufacturers must carefully control:

-

Drill accuracy and tool wear

-

Hole wall smoothness

-

Copper plating thickness consistency

These factors directly affect via reliability in 8 layer PCBs.

Electrical and Thermal Performance Implications

Copper weight influences both electrical and thermal behavior:

-

Higher copper weight supports increased current carrying capacity

-

Improved heat dissipation for power applications

-

Potential signal integrity trade-offs for high-speed circuits

Proper copper weight selection balances performance and manufacturability.

Manufacturing Capability Required for Copper Weight Control

Producing 8 layer PCBs with controlled copper weight requires:

-

Stable etching and plating processes

-

Advanced lamination capability

-

Tight thickness measurement and inspection

-

Engineering experience with multilayer stackups

These capabilities distinguish experienced manufacturers from basic PCB suppliers.

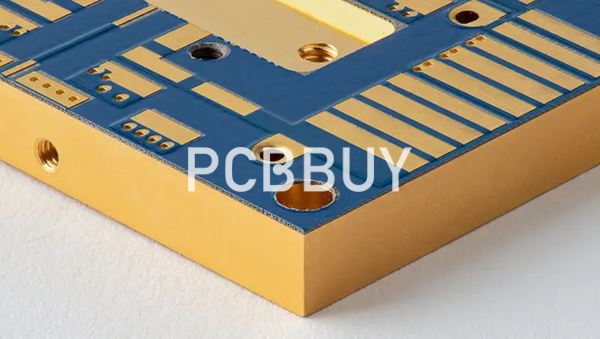

PCBBUY’s Capability in Copper Weight Control for 8 Layer PCB

PCBBUY supports a range of copper weight options for 8 layer PCBs, from standard to heavier copper designs. Through controlled lamination, etching, and plating processes, PCBBUY ensures consistent copper thickness and reliable PCB performance.

Key strengths include:

-

Multilayer stackup optimization support

-

Copper thickness uniformity control

-

Engineering-driven manufacturing processes

-

Export-oriented quality assurance

Design Guidelines for Copper Weight Selection

To improve manufacturability and reliability, designers should:

-

Avoid unnecessary heavy copper on all layers

-

Balance copper weight across the stackup

-

Communicate current and thermal requirements clearly

-

Consult manufacturers early during stackup planning

Early coordination reduces production risk.

Typical Applications Using Controlled Copper Weight 8 Layer PCB

8 layer PCBs with optimized copper weight are commonly used in:

-

Power management systems

-

Industrial automation equipment

-

Communication and networking hardware

-

High-reliability export electronics

Conclusion

Copper weight is a critical factor in the design and manufacturing of 8 layer PCBs.

While heavier copper improves current capacity and thermal performance, it also increases manufacturing complexity.

By combining engineering expertise with controlled production processes, manufacturers like PCBBUY can reliably produce 8 layer PCBs with precise copper weight control and consistent quality.

FAQ

What does copper weight mean in an 8 layer PCB?

Copper weight refers to the thickness of copper on each PCB layer, typically measured in ounces per square foot.

What copper weight is commonly used for inner layers in 8 layer PCB?

Inner layers typically use 0.5 oz to 1 oz copper, while power or ground planes may use heavier copper.

Is heavy copper difficult to manufacture in an 8 layer PCB?

Yes. Heavy copper increases etching difficulty, lamination stress, and drilling complexity, requiring advanced process control.

How does copper weight affect PCB reliability?

Properly controlled copper weight improves electrical and thermal performance, while poor control can lead to defects and reliability issues.

Can PCBBUY support custom copper weight stackups?

Yes. PCBBUY supports customized copper weight stackups with engineering assistance for multilayer PCB designs.

Industry Category