Detailed Explanation of Inner Layer Process for PCB Multilayer Boards

By:PCBBUY 03/01/2024 11:32

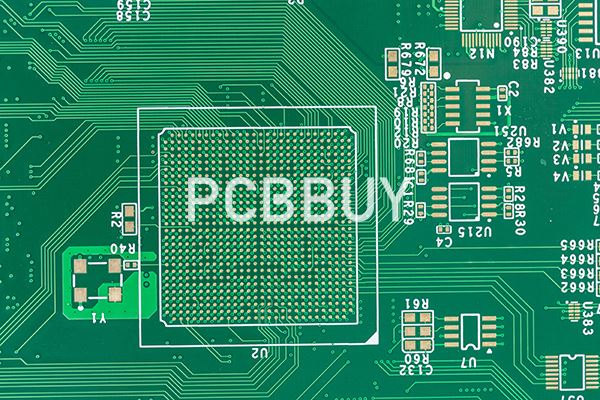

In the electronics manufacturing industry, printed circuit boards (PCBs) play a crucial role as the connecting substrate for electronic components. Particularly, multilayer PCBs have become an indispensable part of modern electronic devices due to their excellent performance and wide range of applications. The inner layer fabrication process of multilayer PCBs is a key aspect of the entire production process, as it determines the performance and quality of the PCBs. This article provides a detailed explanation of the inner layer process for multilayer PCBs to help readers better understand this complex and intricate manufacturing process.

I. Overview of the Inner Layer Fabrication Process

The inner layer fabrication process for multilayer PCBs mainly includes preparing the substrate, cutting the boards, pre-treatment, manufacturing semi-cured sheets, laminating, inner layer circuitry fabrication, inner layer etching, and inner layer inspection. These steps are interconnected and together constitute the complete process of inner layer fabrication for multilayer PCBs.

II. Detailed Step-by-Step Analysis

1. Preparing the Substrate

Preparing the substrate is the first step in the inner layer fabrication process for multilayer PCBs. Suitable base materials such as FR4, CEM-1, aluminum substrates, etc., are selected according to design requirements. These base materials possess good insulation, heat resistance, and mechanical strength to meet the performance requirements of multilayer PCBs. Subsequently, the base materials are cut to the appropriate size using a cutting machine to facilitate further processing.

2. Cutting the Boards

Board cutting involves cutting the PCB substrate into production-sized pieces. Professional cutting machines are used to cut the base materials into dimensions that meet production requirements. It is essential to ensure dimensional accuracy and edge smoothness during the cutting process to facilitate subsequent processing.

3. Pre-treatment

Pre-treatment involves cleaning the surface of the PCB substrate to remove surface contaminants for subsequent processing. Pre-treatment includes cleaning and drying steps to ensure that the substrate surface is clean, dry, and free from oil, dust, and other impurities.

4. Manufacturing Semi-cured Sheets

Manufacturing semi-cured sheets involves the lamination of base materials with copper foil. During the manufacturing process, suitable copper foil thickness and material, as well as appropriate adhesives, are selected. The copper foil is tightly bonded to the base material through processes such as hot pressing to form semi-cured sheets with a certain strength.

5. Laminating

Laminating involves applying dry film onto the surface of the PCB substrate. Dry film is a photosensitive insulating material that is applied to the surface of the semi-cured sheets using a laminating machine to prepare for subsequent image transfer. During lamination, it is essential to ensure the adhesion and flatness between the dry film and the semi-cured sheets to ensure the accuracy and quality of image transfer.

6. Inner Layer Circuitry Fabrication

Inner layer circuitry fabrication is a crucial step in the inner layer process for multilayer PCBs. Using equipment such as exposure machines and developing machines, the circuit pattern is transferred to the semi-cured sheets. The specific process includes placing the semi-cured sheets with dry film into the exposure machine and using ultraviolet light to induce a chemical reaction in the dry film's circuit pattern. Subsequently, the unexposed portion of the dry film is removed through development, leaving behind metal copper foil corresponding to the circuit pattern.

7. Inner Layer Etching

Inner layer etching involves etching away the resin on the inner layer circuitry. Etching solution is used to remove the resin portion on the inner layer circuitry, leaving behind the metal traces. During the etching process, strict control of etching solution concentration, temperature, and etching time is required to ensure uniformity and accuracy of etching.

8. Inner Layer Inspection

Inner layer inspection is the final inspection of the quality and accuracy of the inner layer circuitry. Using equipment such as microscopes and X-ray machines, a detailed inspection of the inner layer circuitry is conducted to ensure that the width, spacing, connections, etc., meet design requirements. Additionally, the integrity and flatness of the inner layer circuitry are evaluated to ensure the quality and performance of the final product.

III. Summary and Outlook

The inner layer fabrication process for multilayer PCBs is a complex and intricate manufacturing process that requires strict operation and quality control. By gaining an in-depth understanding of the specific operations and considerations of each step, we can better grasp the principles and technical requirements of inner layer fabrication for multilayer PCBs. With the continuous development of the electronics manufacturing industry, the technology for inner layer fabrication of multilayer PCBs will continue to innovate and improve, providing stronger support for the performance and quality of electronic devices.

Industry Category