ENIG VS ENEPIG

By:PCBBUY 08/10/2021 17:11

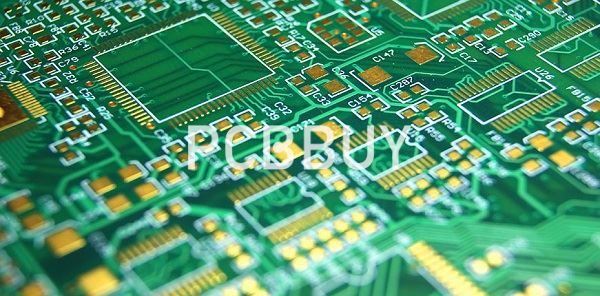

During the manufacturing of PCB, the surface finishing is very important to the finished productions. In this passage, we will focus on the ENIG and ENEPIG. If you are going to learn the difference of them, please check the content we provide for more information.

What is the importance of telling ENIG and ENEPIG?

Copper layer on PCB tends to be oxidized in the air so that copper oxidation tends to be generated, which will seriously lower soldering quality. Surface finish, however, is capable of stopping copper pad from oxidizing so that excellent solderability and corresponding electrical performance can be guaranteed. The uprising market demands on miniaturization, higher functionality and reliability for electronic devices push PCBs towards thinness, light weight, high density and higher speed of signal transmission. Accordingly, surface finishes have to embrace upcoming challenges in terms of stability and reliability to be compatible with development requirement mentioned above.

Moreover, based on rising consciousness of environment-friendly sustainable development, environmental pollution issues concerning PCB surface finishes are attracting increasingly more attention from the globe. The implementation of legislations of RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) laid by EU aims to eliminate the hazardous substances such as lead and mercury from electronic products, calling for green or lead-free manufacturing of PCB surface finish.

Nevertheless, it's a little difficult for people to tell differences between ENIG and ENEPIG, let alone to be aware when to depend on which. The following content in this article will provide definitions of ENIG and ENEPIG and their manufacturing processes, discuss advantages and disadvantages of them and aim to supply a guide on when to use each finish in specific situations.

What is advent of ENIG and ENEPIG?

As early as 1990s, due to PCB development towards finer lines and micro vias plus protruding disadvantages of HASL and OSP, like flatness issues of the former and flux elimination issues of the latter, ENIG started to be used as another alternative for surface finish in multilayer PCB fabrication.

In order to defeat black nickel board, the leading weakness of ENIG, ENEPIG comes out as an upgrading version of ENIG. With plating palladium added between electroless nickel and immersion gold, ENEPIG results in containing a thin layer for resistance whose thickness usually falls in the range from 0.05μm to 0.1μm. Palladium layer plays a role in stopping immersion gold technology from corroding nickel layer. As a result, ENEPIG is capable of defeating the defect of black pad held by ENIG. Furthermore, ENEPIG features highly-reliable wire bonding capability, excellent multiple reflow soldering capability and contains switch contact surface, which makes it able to meet stringent requirement of PCBs with high density and multiple surface packages simultaneously. Based on those advantages, ENEPIG is also called universal finish.

What are the advantages and disadvantages of ENIG and ENEPIG?

In the 1990s, with the development trend of PCB fine lines and micro-via and flatness problems of HASL (hot air solder leveling) and solder elimination problem of OSP (organic solderability preservatives), ENIG technology began to be massively used in PCB fabrication.

Compared with ENIG, ENEPIG technology was applied in PCB fabrication as early as 1980s. However, ENEPIG wasn't been massively used and popularized as a result of its high cost and products' low requirement in terms of surface finish. At present, the requirements of miniaturization, thinness and multiple functions give more opportunities to ENEPIG.

ENEPIG technology develops based on ENIG technology with palladium layer added so that its performance has been highly improved. The reasons are:

a. Palladium layer with dense membrane structure totally covers on nickel layer and phosphorus content in palladium layer is less than ordinary content in nickel layer so that the generation conditions of black nickel is avoided and black pad possibility vanishes.

b. The fusion point of palladium is at 1,554°C that is higher than the fusion point of gold (1,063°C). Therefore, the fusion speed of palladium at a high temperature is relatively slow with sufficient time for the generation of resistance layer to protect nickel layer.

c. Palladium has higher hardness than gold, which results in the improvement of solder reliability, wire bonding capacity and antifriction.

d. Tin-Palladium alloy has the strongest anticorrosion capacity that is capable of stopping the creep corrosion caused by primary cell corrosion so that lifespan can be increased.

e. The usage of palladium is capable of reducing the thickness of gold layer, which downsizes the cost by 60% compared with ENIG.

What is the application comparison of ENIG and ENEPIG?

ENIG and ENEPIG application fields are different based on their distinctive advantages. ENIG is suitable for lead-free soldering, SMT (surface mounted technology), BGA (ball grid array) package etc. The industries and products ENIG is capable of serving include data/telecom, high end consumer, aerospace, military and high performance devices and medical industries. Furthermore, ENIG is especially used in flex market owing to its high reliability.

ENEPIG is capable of meeting more stringent requirements of multiple types of packages including THT (through-hole technology), SMT, BGA, wire bonding, press fit etc. What's better, ENEPIG is also suitable for PCBs with different packaging technologies. As a result, application fields ENEPIG can serve include aerospace, military and high performance devices and medical industries with higher requirement of density and reliability.

Actually, it's PCB board manufacturers' job to provide top-quality products to their customers. As a significant step during PCB manufacturing, high quality of surface finish definitely decides high quality of circuit boards. Therefore, PCB manufacturers have to ensure that surface finish is capable of meeting requirement called by circuit boards and end products they'll serve.

Industry Category