Finished Copper Thickness PCB Guidelines

By:PCBBUY 12/19/2025 16:31

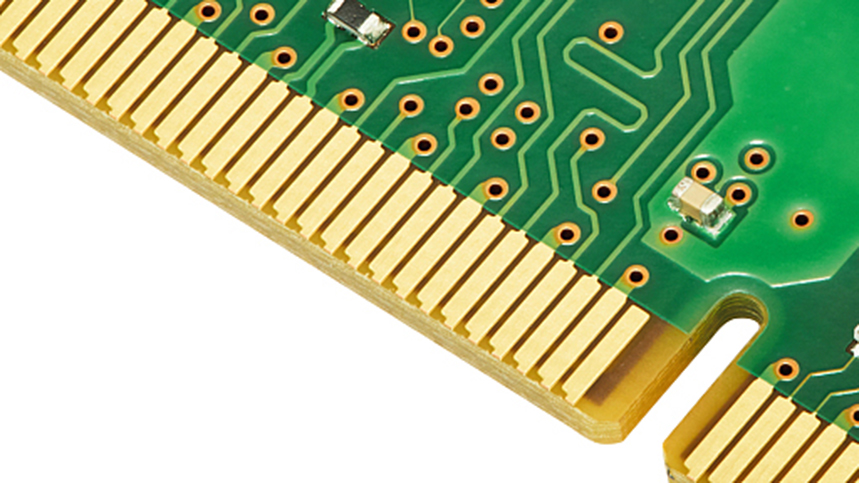

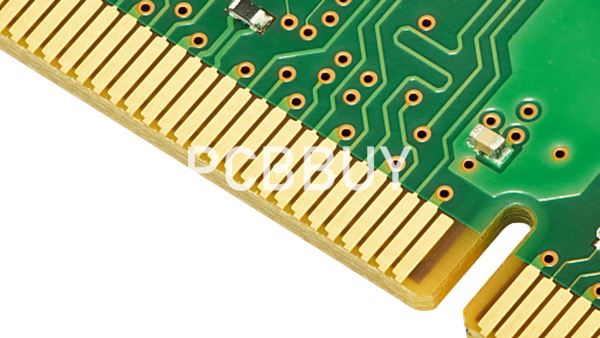

Finished copper thickness PCB refers to the total copper thickness present on conductive layers after plating, patterning, and surface finishing processes. This parameter directly influences electrical resistance, thermal performance, and mechanical integrity.

At PCBBUY, finished copper thickness is not treated as a vague specification—it is a controlled manufacturing result supported by process data and inspection.

What Is Finished Copper Thickness in PCB Manufacturing?

Finished copper thickness refers to the actual copper thickness on PCB traces and planes after all plating and fabrication processes are completed.

This value is different from the original copper foil thickness laminated onto the substrate. During PCB manufacturing, additional copper is deposited through electroplating, which increases the final thickness.

This is why a PCB specified as “1 oz copper” does not automatically mean the finished copper thickness remains exactly 35 μm.

Why Finished Copper Thickness PCB Is Important?

The final copper thickness directly impacts how a PCB performs in real-world applications:

-

Current carrying capability

-

Heat dissipation efficiency

-

Voltage drop stability

-

Mechanical strength of plated through holes

In power electronics, industrial controls, and automotive designs, even small variations in finished copper thickness can affect long-term reliability.

Base Copper vs Finished Copper Thickness PCB

Base copper is the copper foil laminated onto the PCB core, typically ½ oz or 1 oz. Finished copper thickness PCB includes:

-

Base copper thickness

-

Copper added during pattern plating

-

Copper distribution after etching

At PCBBUY, these stages are carefully coordinated to ensure the final copper thickness matches design intent, not just nominal values.

Finished Copper Thickness PCB Reference Table

|

Base Copper |

Typical Plating Add |

Finished Copper Thickness |

|

0.5 oz (18 μm) |

+20–25 μm |

~38–43 μm |

|

1 oz (35 μm) |

+20–30 μm |

~55–65 μm |

|

2 oz (70 μm) |

+25–40 μm |

~95–110 μm |

|

Heavy Copper |

Custom |

Up to 200 μm+ |

PCBBUY Process Control Highlights

|

Process Step |

Control Method |

|

Electroplating |

Current density optimization |

|

Thickness Uniformity |

Panel-level monitoring |

|

Via Copper Thickness |

Aspect ratio–based control |

|

Final Inspection |

Sampling + data verification |

Typical Finished Copper Thickness PCB Options at PCBBUY

PCBBUY supports a wide range of finished copper thickness PCB options, including:

-

Standard outer layers: 1 oz, 2 oz

-

Inner layer copper control for multilayer PCBs

-

Heavy copper designs for power applications

Both single-layer and multilayer PCBs can be manufactured with controlled copper thickness based on application requirements.

How PCBBUY Controls Finished Copper Thickness PCB?

Finished copper thickness control starts from process planning:

-

Optimized electroplating parameters

-

Uniform current distribution across panels

-

In-process copper thickness measurement

-

Post-plating inspection and data verification

This allows PCBBUY to maintain consistent copper thickness across the entire panel, not just isolated areas.

Finished Copper Thickness PCB and Via Reliability

Via reliability depends heavily on copper thickness inside plated through holes. Insufficient copper can lead to cracking during thermal cycling.

PCBBUY applies controlled via plating processes to ensure adequate copper thickness in high aspect ratio designs, improving mechanical durability and electrical continuity.

Design Tips for Finished Copper Thickness PCB

To avoid issues during fabrication:

-

Clearly specify finished copper requirements

-

Allow trace width compensation

-

Consider etching tolerances

-

Communicate high-current areas clearly in fabrication notes

Early DFM review with PCBBUY helps align design intent with manufacturable copper thickness.

Why Choose PCBBUY for Finished Copper Thickness PCB?

PCBBUY combines process experience with engineering support, helping customers achieve stable and repeatable finished copper thickness PCB production for both prototypes and volume orders.

Conclusion

Finished copper thickness PCB is not just a number on a drawing—it is a measurable result of manufacturing control. With PCBBUY’s process discipline and inspection standards, customers gain confidence that their boards will perform as expected in real operating conditions.

Industry Category