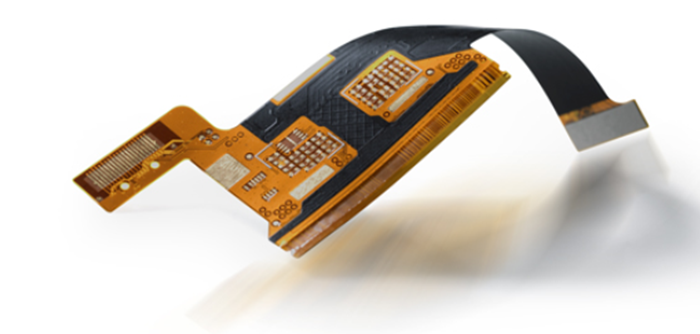

Flexible PCB assembly process

By:PCBBUY 08/02/2021 09:19

There are lots of advantages of flexible PCB such as flexible structure, small volume and light weight. Capable of expanding towards 3D space, flexible PCB improves freedom degree of circuit design and mechanical design. In this passage, we will focus on the assembly process of flexible PCB. Please check and read the content we prepare for more information.

What is the structure of flexible PCB?

In accordance with structural types, flexible PCBs can be classified into the following categories:

· Single-side flexible PCB, which features a simple structure and is easily fabricated.

· Double-side flexible PCB, which features a far more complicated structure than single-side flexible PCB, calling for more control difficulties.

· Multi-layer flexible PCB, which features a more complicated structure than 2-layer flexible PCB and its fabrication quality is more difficult to control.

· Single-side rigid-flex PCB

· Double-side rigid-flex PCB

· Multi-layer rigid-flex PCB

Single-side rigid-flex PCB, double-side rigid-flex PCB and multi-layer rigid-flex PCB are more difficultly fabricated than the first three types of flexible PCBs, featuring far more complex structures.

What is the material of flexible PCB?

Based on structure of flexible PCB, materials contributing to flexible PCB include insulating substrate material, adhesive, metal conductor layer (copper foil) and cover layer. Primary material for flexible PCB has to be flexible insulating film that plays a role as a carrier with excellent mechanical and electrical performance. Ordinary materials include polyester and polyimide film and the latter is used in majority. Along with research and development of new materials, selective materials become so diversified that other types of substrate materials are available like PEN and thin FR4 apart from the ordinary materials.

What are the assembly properties of flexible PCB?

From Flexible PCB to Rigid PCB

Flexible PCB tends to get deformed due to its light weight and thinness, incapable of being directly assembled on SMT manufacturing line like rigid PCB. Thus, to successfully implement assembly on flexible PCB, it has to be fixed on rigid carrier or tray so that it can be dealt with like rigid PCB. Flatness, accuracy of positioning and consistency of board carrier play a key role in completing product quality, which is where flexible PCB assembly focuses on.

Low Density

Up to now, because flexible PCB features higher cost than rigid PCB, majority of flexible PCBs are only applied for connections between modules with different functions based on product cost concern. As a result, the number of components ready to be assembled on flexible PCB is relatively low with low assembly density. Generally speaking, the number of components is within 50 and some boards contain only two connectors.

Large Number of Panels

Flexible PCB is mainly used in miniaturized electronic products such as cell phones and digital cameras so that the area of single board is small. Furthermore, the number of components assembled on single board is quite low, so in order to improve assembly efficiency, panels are usually applied for assembly after which they will be separated through punching.

Wide Applications of Auxiliary fixtures during Assembly Process

Lots of auxiliary fixtures participate in flexible PCB assembly due to its deformation and damage features, including flexible PCB baking fixture, board carrying tray, electrical test fixtures, function test fixtures and cutting fixtures.

High Requirement on Product Quality

Since flexible PCB is usually applied in the environment calling for repeating bending and control accuracy, components assembled on flexible PCB have to be able to meet the demands of their application environment. As a result, flexible PCB calls for higher requirement in terms of cleanliness, anti-static precautions and soldering reliability than rigid PCB. In addition, owing to prevalence and acceptance of lead-free manufacturing technologies, flexible PCB assembly has to face up with some technical challenges.

High Assembly Cost

Compared with rigid PCB assembly, flexible PCB assembly leads to a high overall cost, which is especially true in the starting phase. As a result of wide range of applications of fixtures, long manufacturing period, low rate of equipment utilization, higher demands of accessories and staff and higher requirement on manufacturing environment and product quality.

The application range becomes increasingly larger as electronic products develop and flexible PCB assembly technology constantly improves and become optimized with manufacturing and assembly cost gradually decreasing, which will thereafter lead flexible PCB to step further into wider range of applications.

Industry Category