Future scope of PCB

By:PCBBUY 08/06/2021 17:05

As the basis of all electronic devices, PCBs feel intense pressure for development and growth. With consumers pushing for slimmer and faster devices, and with industries seeking improved functionality, the PCB must continue developing into the future.

What is the future of PCB?

1. PCB Board Cameras

Board cameras, alternatively called PCB cameras, are cameras that are mounted directly onto a circuit board. These PCB cameras consist of a lens, aperture and image sensor and are designed to take both digital pictures and videos.

Due to their size, board cameras have several applications across a variety of industries. These include:

• Consumer Electronics: Board cameras have found a great deal of utility in consumer electronics, particularly in handheld mobile devices. Today, smartphones, tablets, laptops and other small handheld electronics commonly use board cameras. Consumer electronics companies are constantly pushing for smaller and more powerful cameras.

• Medical Instruments: In particular, small board cameras have found a niche in the medical industry for non-invasive and minimally invasive procedures. Pill-sized cameras are now in use that can be swallowed by patients so doctors can take comprehensive videos and images from inside the digestive tract without invasive surgery. Also wearable cameras are gaining traction during surgeries as an instructional tool.

• Surveillance Technology: Because PCB cameras are so small in size, they are easy to conceal inside objects, making them an excellent choice for surveillance uses. Many consumers, security companies and organizations use these small cameras to monitor their homes and businesses for intruders. As the technology improves, its surveillance applications continue to grow.

2. 3D Printed Electronics

3D printing technology is probably one of the most exciting technological innovations in recent years. From 3D-printed organs to firearms and ammo, 3D printing has accomplished some incredible things in a variety of industries. The PCB industry is no different.

3D PE can potentially provide immense technical and manufacturing benefits for both circuit manufacturing companies and their clients — especially when compared to traditional 2D PCBs. These advantages include:

• Novel Designs: By allowing circuits to be printed on top of an existing shape, 3D PE manufacturing techniques enable circuits to take new and incredible shapes that were simply not possible with traditional PCB manufacturing. 3D PEs can be shaped to fit any circuit carrier while still combining electronic, optic and mechanical functions. This enables new product features and optimizations. Not only can 3D PEs be shaped, but they can also be scaled to print on components larger than anything possible using 2D PCB manufacturing methods.

• Improved Efficiency: Since 3D PE manufacturing is an additive process that uses digital methods, it is much more conservative in its materials usage than 2D PCB manufacturing. The system only applies as much material as is needed and nothing more, meaning materials are used more efficiently. Additionally, the digital aspect of the production process increases overall accuracy by removing sources of human error. While circuits will still sometimes fail using this method, increased automation reduces the likelihood of failure, improving overall efficiency.

• Environmentally Friendly: Since there is no actual limitation on the type of substrate material that can be used in 3D PE manufacturing, PCB Houses can select any material they like. This makes environmentally-friendly production much easier as they can choose low-cost, recyclable materials.

3. PCB Autoplacers

Most PCBs today include an autorouter in their design. This PCB component routes electronic functions throughout a board to model the characteristics of the PCB layout, therefore making the automation process much easier.

As of today, automatic placement tools haven't achieved acceptance in the PCB manufacturing industry at large. The reason lies primarily in the difference between autoplacer and autorouter constraints:

• Autorouters: Routing constraints are mainly dictated by the characteristics of the board, which can be easily modeled within the PCB design environment. These properties include the number of layers, the spacing between tracks, connection distances and layer directions.

• Autoplacers: The constraints that dictate component placement can be driven by mechanical considerations. These include the shape of the product casing, ergonomic issues like button positioning, heat dissipation and pick-and-place optimization.

4. High-Speed Capabilities

Today's world is incredibly fast-paced, demanding that people and technology move quickly as well. As the years pass, we expect things to get even faster - that includes electronics. To allow our devices to keep up with this growing demand for speed, PCB technology will need to adapt accordingly.

The generally agreed-upon definition of a high-speed PCB is one where the integrity of the signal is affected by the circuit layout. This can mean different things:

• Digital Signal: In digital PCB signals, the intelligence is contained in the digital pulses. Therefore, effects on signal integrity can manifest as delayed or canceled digital signals.

• Analog Signal: In a high-speed analog circuit, the intelligence is in the shape of the signal. In these cases, signal integrity problems will appear as altered signal shapes.

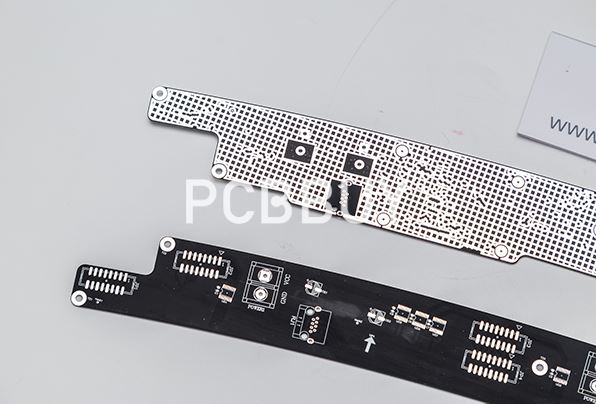

5. A Focus on Flexible PCBs

Several industries are pushing the trend toward flexible PCBs, including:

• LED Lighting: LED lighting is wildly popular as a bright yet energy-efficient alternative to traditional incandescent bulbs. For LED strip lighting, flexibility is key along the length of the strip so customers can bend the strip to suit their needs. Flexible PCBs bring about this necessary functionality.

• Wearable Technology: Today, wearable electronic devices are becoming ever more popular, with the global market expected to reach $30.6 billion by 2020. These electronics are often embedded into clothing and flexible accessories such as smart socks, belts and wristbands. Even some sports helmets now incorporate sensors, using PCBs, to monitor shock and speed. Flexible PCBs are necessary for these applications, both for the sake of flexibility and for handling shock and vibration.

• Flexible Displays: Flexible displays have enjoyed attention for years but are still relatively rare to find and aren't in general use yet due to the high manufacturing costs. However, once those production costs come down, flexible devices are expected to be the next big thing in mobile technology. Able to handle shocks and stresses better than typical rigid designs, flexible displays will be likely to lead to flexible smartphones and tablets. This will probably require everything else in the device to be bendable as well, including PCBs.

• Medical Instrumentation: Medical device innovation has so far focused mostly on two technology trends: miniaturization and flexibility. Flexible multilayer PCBs enable medical device designers to accomplish both, by allowing for compact circuitry on a flexible substrate. Flexible PCBs are also favored for their reliability and biocompatibility, as their connections are consistent and their substrates are compatible for contact with human tissues.

6. Biodegradable PCBs

Electronic waste, AKA e-waste, is one of the biggest environmental concerns of the modern era. This type of waste includes electronic items like computers, laptops, TVs, smartphones and household appliances, many of which contain parts that are neither biodegradable nor environmentally-friendly. While e-scrapping has become popular in recent years, e-waste continues to be a problem as people try to find ways to get rid of old electronics.

PCBs are a large part of this issue. Some PCB materials don't degrade very well and often end up in landfills, polluting the surrounding soil. This issue is compounded by the fact that the chemicals used during PCB manufacturing process are often harmful to the environment if not properly disposed of.

Considering how many electronics the average consumer goes through over the course of a decade, along with the industry trend toward short-lived electrical products, this can mean a lot of thrown-out PCBs bringing harm to the environment.

Industry Category