HASL Lead Free A Eco-Friendly PCB Surface Finish

By:PCBBUY 07/30/2025 15:11

Introduction to HASL Lead Free Surface Finish

In the world of printed circuit boards (PCBs), surface finish plays a critical role in ensuring solderability, reliability, and environmental compliance. One of the most popular and cost-effective finishes today is HASL (Hot Air Solder Leveling). However, with increasing environmental regulations, the HASL lead free version has become a preferred choice across many industries.

At PCBBUY, we specialize in manufacturing PCBs with high-quality HASL lead free surface finishes, adhering strictly to RoHS standards and offering solderable, durable results with precision thickness control ranging from 2μm to 40μm.

What Is HASL Lead Free and How Does It Work?

HASL lead free is a surface finish process in which a lead-free solder alloy—typically composed of Sn/Ag/Cu (Tin, Silver, Copper)—is applied to exposed copper surfaces to protect them from oxidation and ensure reliable soldering during assembly.

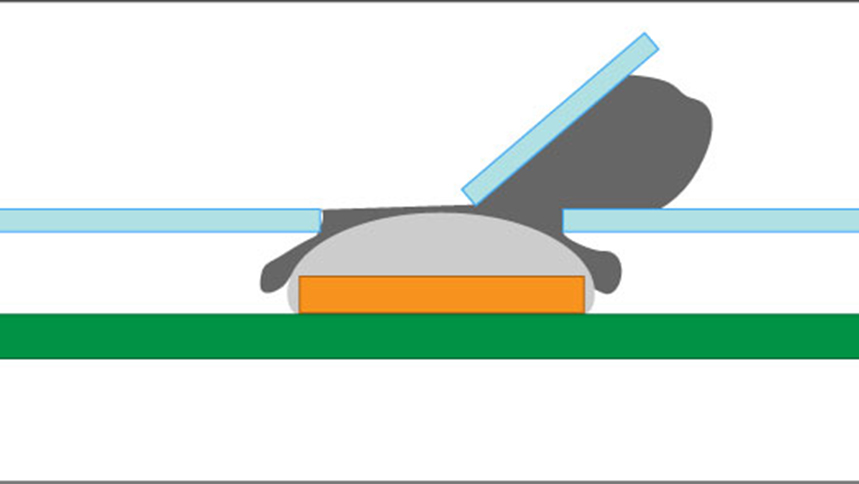

The process flow involves:

-

Cleaning the copper surface.

-

Flux coating to promote solder adhesion.

-

Dipping the board into molten lead-free solder alloy.

-

Hot air knives remove excess solder and level the surface.

This finish results in a solderable coating with a long shelf life and good performance in thermal cycling conditions.

HASL Lead Free vs Traditional HASL: What’s the Difference?

|

Feature |

HASL (Leaded) |

HASL Lead Free |

|

Alloy Composition |

Sn63/Pb37 |

Sn/Ag/Cu |

|

RoHS Compliance |

❌ No |

✅ Yes |

|

Soldering Temperature |

~183°C |

~217°C |

|

Environmental Impact |

High (toxic lead) |

Low (eco-safe) |

|

Application Areas |

Declining usage |

Widely accepted |

At PCBBUY, we recommend HASL lead free for customers seeking RoHS compliance without sacrificing quality or cost-efficiency.

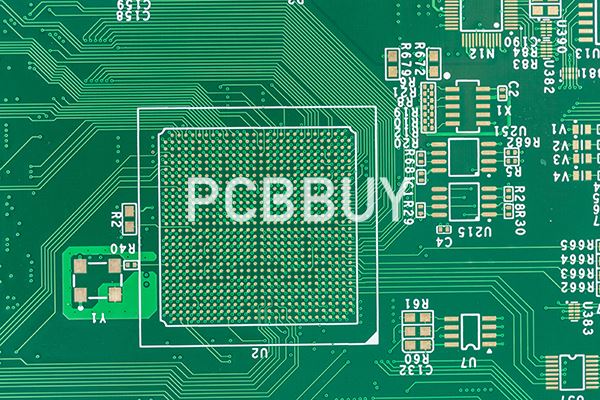

HASL Lead Free Thickness Specification at PCBBUY

We maintain tight control over our surface finish parameters to ensure consistent and reliable results. For HASL lead free, PCBBUY offers:

-

Thickness range: 2–40μm, depending on board design and application.

-

Alloy used: Sn96.5/Ag3.0/Cu0.5

-

Applicable PCB types: Single-layer, double-layer, and multilayer boards.

-

Minimum pad size: 0.2mm

-

Max board size: 650mm (custom sizes available upon request)

All finishes undergo automated thickness inspection to guarantee consistency across batches.

Advantages of HASL Lead Free in PCB Manufacturing

✅ RoHS and REACH Compliant

✅ Cost-Effective for large-scale production

✅ Excellent solderability for wave and hand soldering

✅ Good shelf life and resistance to oxidation

✅ Widely supported by standard assembly lines (SMT, THT)

Compared to more expensive finishes like ENIG or ENEPIG, HASL lead free offers a balanced solution in terms of price, performance, and regulatory compliance.

HASL Lead Free Surface Finish Process at PCBBUY

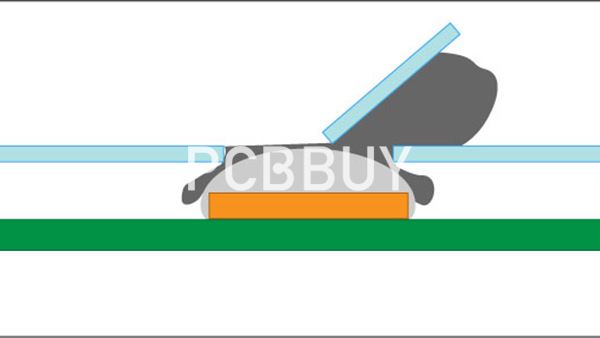

Our dedicated surface finish line is optimized for lead-free processing, using automated immersion tanks and hot-air leveling systems. The key stages include:

-

Pre-cleaning and deoxidation of copper pads.

-

Flux application with anti-oxidation agents.

-

Controlled immersion in molten Sn/Ag/Cu alloy.

-

High-precision hot air knives (above 300°C) to control thickness.

-

Final inspection using XRF measurement tools.

PCBBUY’s engineers ensure that every batch meets customer specifications and IPC Class 2 or Class 3 standards.

Applications of HASL Lead Free PCBs

The reliability and cost-efficiency of HASL lead free make it ideal for:

-

Consumer electronics

-

LED lighting boards

-

Automotive electronics

-

Industrial control systems

-

Educational development kits

If your product requires RoHS compliance, HASL lead free is the go-to choice—particularly for high-volume orders that still demand good solder performance.

Why Choose PCBBUY for HASL Lead Free Surface Finish?

As a trusted high-end PCB manufacturer, PCBBUY stands out with:

-

Over 10 years of process expertise

-

Advanced hot air solder leveling lines

-

Real-time thickness monitoring systems

-

Professional DFM (Design for Manufacturability) reviews

-

Fast prototype to mass production turnaround

-

Global shipping and multilingual technical support

Whether you need a simple 2-layer board or a complex multilayer HDI board with HASL lead free finish, PCBBUY ensures high reliability and consistent quality.

Frequently Asked Questions (FAQ)

Q: Can HASL lead free be used for BGA and fine-pitch components?

A: While not as flat as ENIG, our precise leveling allows for use with most SMT components, including mid-range BGA.

Q: What is the shelf life of HASL lead free boards?

A: Up to 6–12 months when stored in dry, anti-static packaging.

Q: Is HASL lead free more expensive than HASL?

A: Slightly, due to alloy cost and process control, but still cost-effective compared to ENIG or OSP.

Conclusion

HASL lead free has become an industry-standard finish for environmentally friendly and reliable PCB manufacturing. At PCBBUY, we combine precise process control with global delivery capability to provide customers with superior HASL lead free solutions that meet both performance and compliance standards.

Contact PCBBUY now for a free quote or sample evaluation on your next HASL lead free PCB project!

Industry Category