Hard Gold and Selective Gold PCB

By:PCBBUY 11/27/2025 16:34

Surface-finish technology plays a critical role in determining contact reliability, corrosion resistance, and mechanical durability of printed circuit boards. Among the various finish options, hard electroplated gold and selective gold plating are widely used in high-performance applications. This document provides a technical explanation of both finishes and outlines PCBBUY’s production capabilities.

These finishes protect your PCB, improve electrical performance, and make sure your product stays reliable even after years of use. In this article, we’ll break down what hard gold and selective gold plating really mean and how PCBBUY brings these processes to a higher manufacturing standard.

What Is Hard Gold?

Hard gold is a type of electroplated gold that mixes pure gold with small amounts of hardening elements—usually cobalt. This makes the surface extremely durable, abrasion-resistant, and ideal for parts that undergo frequent friction.

Key Benefits of Hard Gold

-

High hardness & wear resistance

-

Long-term durability for repeated insertions

-

Smooth, shiny appearance

-

Excellent conductivity for connectors

Hard gold is most commonly used on:

-

Gold fingers

-

Edge connectors

-

Switch contact points

-

High-frequency connecting components

If your product needs connectors that can withstand thousands of cycles, then hard gold is the reliable option.

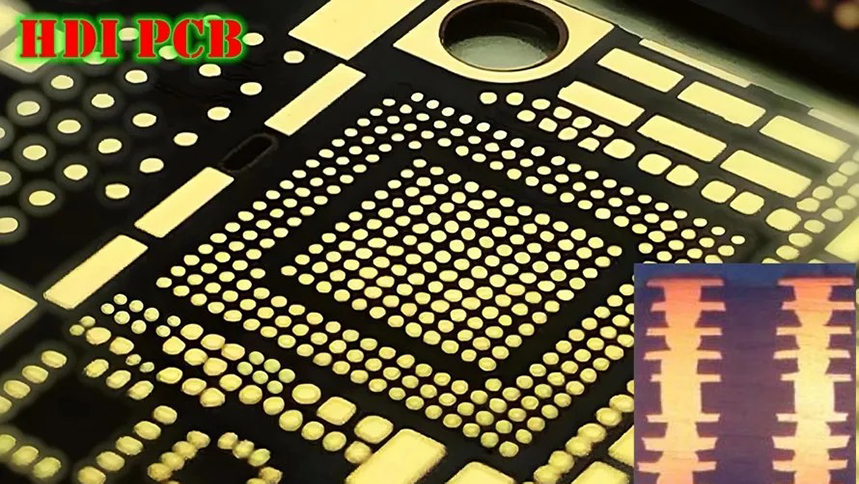

What Is Selective Gold PCB?

A selective gold PCB means only specific areas of the board are treated with gold—rather than plating the entire board. This can include hard gold or ENIG, depending on the design.

The goal is simple:

Enhance performance where needed, and reduce cost where it’s not.

Advantages of Selective Gold

-

Cost-effective compared to full gold plating

-

Allows different surface finishes in different areas

-

Improves solderability on designated pads

-

Ensures durability and conductivity on important contact points

Typical selective-gold areas include:

-

Gold fingers

-

BGA pads

-

High-frequency component pads

-

Plug-in connectors

Hard Gold vs Selective Gold — What’s the Difference?

|

Parameter |

Hard Gold |

Selective Gold |

|

Deposition Method |

Electroplating |

Masked electroplating or ENIG targeting specific locations |

|

Thickness |

5–50 µin |

Flexible, depending on function |

|

Hardness |

Very high |

Varies based on gold type |

|

Solderability |

Poor |

Excellent (when ENIG is used) |

|

Cost |

Higher |

More economical |

Many PCBs use both techniques together, balancing cost and reliability.

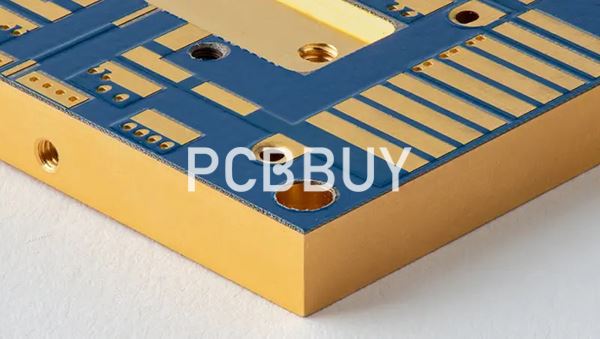

PCBBUY’s Capabilities for Gold Surface-Finish PCBs

PCBBUY specializes in both hard gold and selective gold solutions, supported by advanced factory equipment and strict quality control standards.

1. Precision Gold Plating Lines

-

Controlled gold thickness options from 5–50 µin

-

Even, smooth surface with low roughness (Ra)

-

Automated plating to maintain consistency

2. Professional Gold Finger Manufacturing

-

Accurate beveling at 30° or 45°

-

Smooth, defect-free edge machining

-

High wear-resistance validation through abrasion testing

3. High-Accuracy Selective Plating

-

Laser-aligned masking ensures exact plating boundaries

-

Perfect for boards with mixed surface-finish regions

-

Zero contamination between gold and solder-finish areas

4. Strict Inspection & Quality Assurance

PCBBUY uses:

-

XRF thickness measurement

-

Microscope surface inspection

-

Plating bath purity monitoring

-

Electrical contact resistance testing

This ensures every gold-finished PCB meets international quality standards.

Industries Using Hard Gold and Selective Gold PCBs

-

Telecommunications

-

Industrial automation

-

Automotive electronics

-

High-frequency communication modules

-

Medical equipment

-

Consumer electronics requiring durable connectors

Why Choose PCBBUY?

✔ Stable high-precision gold-plating production lines

✔ Competitive factory-direct pricing

✔ Strict quality control throughout the process

✔ Fast delivery for both prototypes and batch production

Whether you need durable gold fingers or cost-optimized selective-gold pads, PCBBUY can support complex designs with consistent quality.

Conclusion

Hard gold and selective gold PCBs are essential for modern electronics requiring durability, conductivity, and long-lasting performance. With advanced equipment and experienced engineers, PCBBUY offers reliable and flexible gold surface-finish solutions for a wide range of industries.

FAQ

1. What is the difference between hard gold and selective gold PCB?

Hard gold PCBs use electroplated gold with high hardness and excellent wear resistance, ideal for connectors and edge contacts. Selective gold PCBs apply gold only on required areas, combining cost efficiency with performance.

2. Why choose hard gold for PCB edge connectors?

Hard gold provides superb durability, abrasion resistance, and long-term reliability, making it suitable for repeated mechanical contact, such as card-edge interfaces and high-cycle connectors.

3. Is selective gold plating more cost-effective than full hard gold?

Yes. Selective gold plating applies gold only where needed, reducing overall gold usage and significantly lowering cost while maintaining functional performance.

4. What thickness is standard for hard gold plating?

Common hard gold thickness ranges from 0.5μm to 2μm, depending on connector durability requirements. PCBBUY supports customized gold thickness based on IPC standards.

5. What is ENIG and how is it different from hard gold?

ENIG (Electroless Nickel Immersion Gold) uses soft gold with thin thickness for solderability, while hard gold is electroplated with higher hardness and better abrasion resistance. They serve different applications.

6. Can PCBBUY manufacture selective gold PCBs for high-frequency boards?

Yes. PCBBUY provides selective gold, hard gold, ENIG, and mixed finishing options optimized for RF, high-speed, and multilayer HDI PCBs.

7. What PCB designs benefit the most from selective gold plating?

Selective gold is ideal for:

-

BGA/IC contact pads

-

Keypad surfaces

-

High-reliability switching interfaces

-

Partial gold areas on mixed-finish PCBs

8. Does gold thickness affect impedance performance?

In most cases, gold thickness has minimal effect on impedance, but PCBBUY provides impedance-controlled stackups considering finish type, copper thickness, and trace geometry.

9. What industries commonly use hard gold PCBs?

Hard gold PCBs are widely used in:

-

Automotive electronics

-

Industrial equipment

-

Telecom modules

-

Aerospace and defense

-

High-durability connectors

10. Can PCBBUY provide customized gold-plating solutions?

Absolutely. PCBBUY supports:

-

Hard gold

-

Selective gold

-

ENIG

-

Gold fingers

-

Mixed finishes

-

Custom plating thicknesses

Industry Category