High Voltage PCB Spacing Guidelines

By:PCBBUY 11/28/2025 17:32

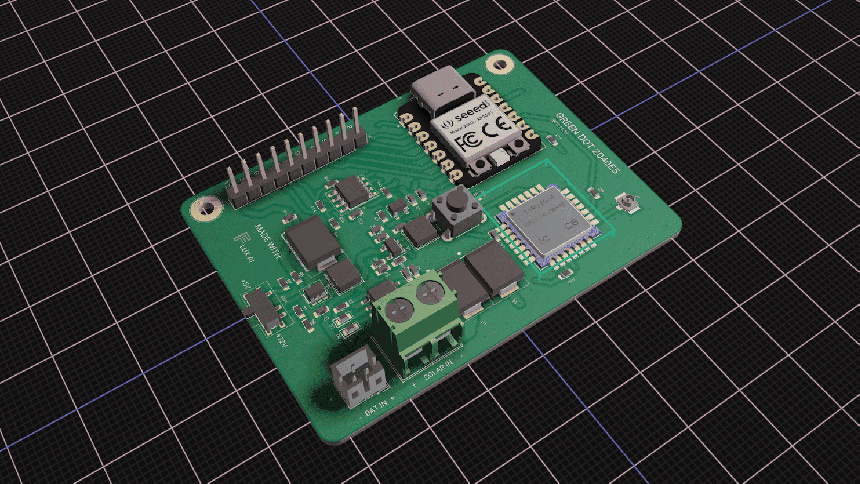

High-voltage electronic products—such as power supplies, EV controllers, charging modules, and industrial automation systems—require far more than standard PCB design rules. One of the most important factors that determines the safety, reliability, and long-term performance of these boards is high voltage PCB spacing.

In this article, we will walk through what high-voltage spacing really means, why it matters, and how PCBBUY supports global customers with professional high-voltage PCB manufacturing.

What Is High Voltage PCB Spacing?

High-voltage PCB spacing refers to the minimum distance required between conductive elements on a PCB to prevent electrical arcing, tracking, or breakdown. It includes two key concepts:

1. Clearance

The shortest distance through air between two conductors.

2. Creepage

The minimum distance along the PCB surface between conductors.

Both play a critical role in ensuring that the PCB can withstand high voltage without insulation failure. Standards like IPC-2221 and UL guidelines define the minimum spacing required for different voltage levels.

What Affects High Voltage PCB Spacing?

Several factors influence how much spacing a board requires:

1. Operating Voltage and Surge Voltage

Higher voltage means larger spacing. Surge or transient voltage also needs to be considered.

2. Environmental Conditions

Humidity, dust, and pollution affect creepage distance requirements.

3. PCB Material

Different materials offer different CTI (Comparative Tracking Index) values.

Higher CTI = better insulation performance.

4. Solder Mask and Coatings

Conformal coating can reduce creepage requirements, while exposed copper increases the needed spacing.

5. PCB Layer Structure

Internal layers do not require the same spacing as external layers because they are insulated by dielectric material.

Recommended High Voltage PCB Spacing (Based on IPC-2221)

Below is a simplified guideline:

|

Voltage Range |

Minimum Clearance |

|

0–30V |

0.1 mm |

|

31–150V |

0.6 mm |

|

151–300V |

1.2 mm |

|

301–600V |

2.4 mm |

|

601–1000V |

5.0 mm |

(Values may vary depending on environment, pollution degree, and CTI rating)

PCBBUY’s High-Voltage PCB Manufacturing Capabilities

As a professional PCB manufacturer, PCBBUY provides specialized production processes designed for high-voltage and high-power applications.

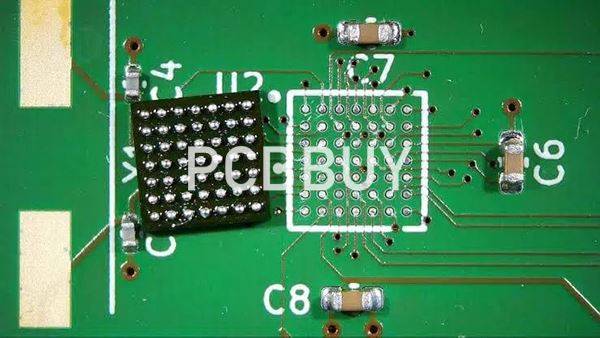

1. Precise Spacing Control

-

Minimum external spacing capability: 0.5 mm for high-voltage applications

-

LDI exposure improves consistency and accuracy

-

Strict solder mask alignment prevents unintended bridging

2. Multiple High-Voltage-Rated Materials

PCBBUY offers a full range of materials including:

-

High-TG FR4

-

FR4 with CTI 600 options

-

Rogers high-insulation laminates

-

Ceramic substrates for ultra-high-voltage designs

3. High-Voltage Testing (Hipot)

PCBBUY supports optional:

-

DC Hipot

-

AC withstand voltage test

-

Leakage current measurement

These ensure that every board can handle the required working voltage safely.

4. Advanced Engineering Support

Before production, PCBBUY’s engineering team provides DFM checks focused on:

-

Clearance and creepage compliance

-

Arc-risk areas

-

Slotting, routing, and insulation enhancements

Design Tips for Better High Voltage PCB Spacing

-

Increase distance between high-voltage nets

-

Add milling slots or grooves to extend creepage

-

Use conformal coating for compact layouts

-

Avoid acute angles on high-voltage traces

-

Keep high-voltage areas separated from low-voltage circuits

-

Use wide copper traces to reduce heating

These simple improvements can significantly enhance the board’s durability.

Why Choose PCBBUY for High-Voltage PCBs?

-

Reliable spacing accuracy

-

Strict quality control aligned with IPC standards

-

Advanced inspection and LDI imaging

-

High-voltage test options

-

Fast production and competitive pricing

PCBBUY has supported industries such as EV systems, industrial automation, solar inverters, and high-power chargers—where high-voltage requirements demand precision and consistent quality.

Conclusion

High voltage PCB spacing is one of the most critical design considerations in power electronics. Choosing the right spacing not only improves safety but also enhances product lifespan and performance.

With professional manufacturing capabilities, engineering support, and advanced quality control, PCBBUY is equipped to deliver safe and reliable high-voltage PCB solutions for global customers.

⭐ FAQ

1. What is high voltage PCB spacing?

It is the minimum clearance and creepage required between conductors to avoid arcing or electrical breakdown.

2. What standard defines high voltage PCB spacing?

IPC-2221 is the most commonly used reference.

3. How much spacing is needed for 300V–600V circuits?

Typically 1.2–2.4 mm, depending on environment and material.

4. Can PCBBUY manufacture high-voltage PCBs?

Yes. PCBBUY supports materials up to CTI 600 and offers Hipot testing.

5. Does solder mask reduce spacing requirements?

Yes, but only slightly. For extreme voltages, mechanical isolation is still recommended.

6. How do I design high-voltage areas effectively?

Use wider spacing, add slots, and apply conformal coating.

Industry Category