Hot Air Leveling

By: 03/22/2024 11:09

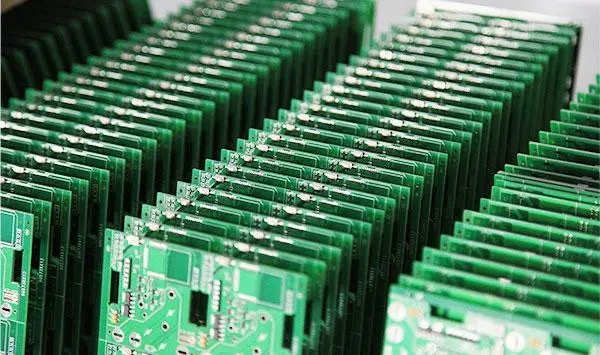

With the rapid development of the electronics industry, printed circuit boards (PCBs), as fundamental components of electronic devices, play a crucial role in the stability and reliability of the entire equipment. Surface treatment is an indispensable process in PCB manufacturing, and as a common surface treatment technique, tin spraying technology is widely used to enhance the solderability and electrical performance of PCBs. This article will provide a detailed introduction and analysis of PCB tin spraying technology.

Overview of Tin Spraying Technology

Tin spraying technology, also known as hot air leveling, is an important surface treatment technology in the electronics industry. This technique forms a uniform and dense tin film on the surface of the PCB through spraying to enhance the solderability and electrical performance of the PCB.

The basic principle of tin spraying technology is to utilize the melting and semi-volatile properties of tin metal at high temperatures. Tin powder is mixed with high-temperature gas and uniformly sprayed onto the surface of the PCB through a nozzle. During the spraying process, it is necessary to strictly control parameters such as spraying speed, pressure, and temperature to ensure the quality and uniformity of the tin film. After spraying, curing treatment is required to firmly attach the tin film to the surface of the PCB.

If you want to order PCB product, please check and custom your order online.

Tin spraying technology has advantages such as simple operation, low cost, and significant effects. It can quickly and accurately form a protective tin film on the surface of the PCB, improve the corrosion resistance and solderability of the PCB, thereby extending the service life and reliability of electronic devices. Additionally, tin spraying technology can reduce solder residues, decrease the failure rate of electronic components, and improve production efficiency and quality.

However, tin spraying technology also faces challenges and issues that need attention. For example, strict control of environmental conditions and operating parameters is required during the spraying process to avoid phenomena such as unevenness and detachment of the tin film. Additionally, tin spraying equipment requires regular maintenance to ensure normal operation and prolong service life.

Tin Spraying Process

Pre-treatment: Before tin spraying, the PCB needs to undergo pre-treatment, which includes cleaning the surface of the PCB to remove oil, oxides, and other impurities, ensuring that the tin powder can firmly adhere to the surface of the PCB. Pre-treatment usually involves chemical cleaning methods, using acid-base solutions or organic solvents for immersion and cleaning of the PCB.

Spraying solder mask: After pre-treatment, a layer of solder mask needs to be sprayed on the surface of the PCB. Solder mask is a special coating that can protect and fix the tin powder during tin spraying. When spraying solder mask, it is necessary to ensure that the coating is uniform and of appropriate thickness to avoid affecting the subsequent tin spraying effect.

Tin spraying operation: After spraying solder mask, tin spraying operation can be carried out. Tin spraying equipment usually consists of a tin powder supply system, spraying system, and control system. During tin spraying, tin powder and air are mixed and uniformly sprayed onto the surface of the PCB through a nozzle. Parameters such as spraying speed, spraying pressure, and spraying temperature need to be controlled to ensure the quality and uniformity of the tin film. To avoid waste and contamination of tin powder, it is also necessary to handle and recycle the waste gas and residues generated during the spraying process.

Curing treatment: After tin spraying is completed, the PCB needs to be sent to a constant temperature oven for curing treatment. The purpose of curing treatment is to firmly attach the tin film to the surface of the PCB, improving its durability and reliability. The curing temperature and time need to be determined according to specific process requirements and PCB material to avoid damage to the PCB caused by excessively high or low temperatures.

Precautions for Tin Spraying Technology

Selection of solder paste: The composition and quality of solder paste have a crucial impact on the tin spraying effect. When selecting solder paste, factors such as melting point, wettability, conductivity, and stability need to be considered to ensure that the tin film formed after tin spraying has good solderability and electrical performance.

Control of operating environment: Tin spraying operation needs to be carried out in a clean and purified environment to avoid the influence of dust and contamination on the quality of the tin film. At the same time, it is necessary to control the temperature and humidity of the operating environment to ensure the stability and fluidity of tin powder during spraying.

Training of operators: Tin spraying technology requires operators with high skills, who need to undergo professional training and assessment. Operators need to be familiar with the operation and maintenance of tin spraying equipment, understand the adjustment and optimization methods of spraying parameters, to ensure the safety and stability of the tin spraying process.

Quality inspection and control: During tin spraying, quality inspection and control need to be carried out on each batch of PCBs. Inspection items include the thickness, uniformity, and adhesion of the tin film to ensure that the tin spraying quality meets process requirements and customer standards. Additionally, regular maintenance and maintenance of tin spraying equipment are required to ensure its normal operation and prolong its service life.

Conclusion

As one of the common surface treatment technologies in the electronics industry, PCB tin spraying technology plays an important role in improving the solderability and electrical performance of PCBs. Through the introduction and analysis in this article, it can be seen that tin spraying technology has advantages such as simple operation, low cost, and significant effects. However, it also faces some challenges and issues that need attention. Therefore, in practical applications, various factors need to be comprehensively considered to select appropriate tin spraying process parameters and equipment conditions to ensure the quality and performance of PCBs reach the best state.

Industry Category