How Local PCB Contract Manufacturers Are Uniquely Qualified?

By:PCBBUY 11/09/2023 15:42

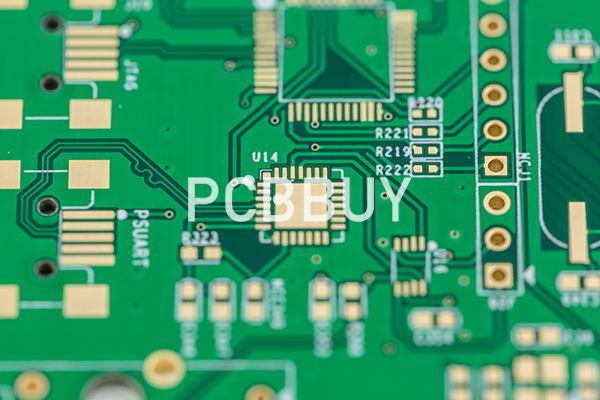

Previously converting a concept into a finished product required a lot of time and effort. With 3D printing, the process is significantly accelerated. It significantly cuts down the time required to create the prototype. For this reason, you can also make any changes in the design easily.

When selecting a rapid PCB prototyping manufacturer, there are a few key features and services that you should expect. How to find in a Rapid PCB Prototyping Partner?

Instant Quotes

If the vendor can’t get you a quote for your prototype in seconds, don’t expect anything else about the process to be quick. You should be able to find out how much your project will cost right away.

Online Management App

It is the combination of a cloud application and the back end manufacturing process that makes rapid PCB prototyping possible. Look for a solution with an easy-to-use portal for ordering, quoting, change management, and project tracking.

House Parts

One way that modern electronics components manufacturers keep costs down is by retaining an inventory of commonly used parts that designers can purchase at a reduced cost. This allows the vendor to purchase a larger quantity and spread the savings across all of their customers.

Onshore Manufacturing

There are a lot of good reasons to choose a partner that manufacturers your prototype in the United States. Speed is a big one. Rapid PCB prototyping is difficult, if not impossible, if overseas shipments are involved.

In-House Assembly

Not all rapid PCB prototyping services operate their own assembly line, but instead send your designs to a 3rd party manufacturing service. Watch out for outsourced PCB assembly as it adds additional points of failure which may delay or kill your project.

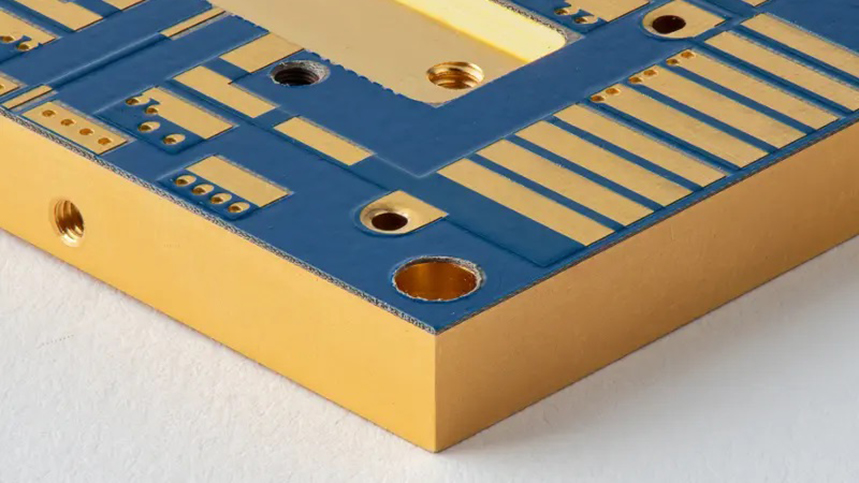

Ability to work with different materials

Materials will add up, layer by layer, and the coupling prevents the board from constraining the circuits. These connections have been borderline impossible given modern circuit board technology. Additionally, 3D circuit board manufacturing only uses materials that are essential to production.

Testing of the product

In-depth validation of the product is a major benefit to 3D PCB prototypes. By using this technology you can identify costly mistakes before they reach the production stage. Rapid prototyping allows you to detect mistakes and errors early on and make necessary amends in time. Thanks to reduced development time, designers have greater freedom to break design for manufacturing rules that are inherent in subtractive PCB manufacturing processes.

Cost Optimisation and Lower Costs

A major benefit of the technology is its cost-optimisation. 3D printers are becoming far more affordable. It is no longer just restricted to large businesses. Rapid prototyping is a big boon for startups who are dealing with limited budgets and need to showcase a minimum viable product to potential investors. With the quick realisation of your product concept, PCB prototyping also gives you the freedom to fail faster. You have the ability also to improve your product before it goes in for final production.

Acceleration of the Printed Circuit Board manufacturing process

Previously converting a concept into a finished product required a lot of time and effort. With 3D printing, the process is significantly accelerated. It significantly cuts down the time required to create the prototype. For this reason, you can also make any changes in the design easily.

Not only does 3D printing save time, it prevents you from any rude shocks at a later time. Get reliable validation of your product or insights into any changes required with your completed prototype.

How Local PCB Contract Manufacturers Are Uniquely Qualified?

Here are some of the advantages that you will find with a locally based PCB contract manufacturer that lends itself well to the current crisis:

Location: Being located locally, you won’t have to worry about the time differences or shipping problems that can happen using offshore manufacturers to build your medical equipment. You can quickly and efficiently communicate your needs to the local PCB CM in order to get the project started and completed in as little time as possible.

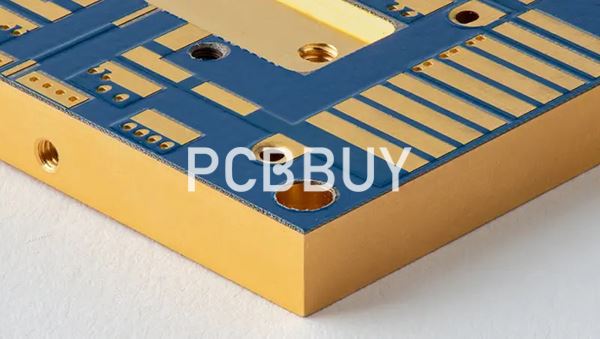

Capabilities: Not only can you get your circuit boards built by the CM, but they often have other services that can help with your project as well. Cables, wire harnesses, and box building capabilities under one roof will help you to not only get your project built perfectly to your specifications but will also help get it finished as soon as possible.

Engineering: Local PCB CMs usually have a well-staffed engineering department that will help you validate your design before production, and can also help you with the design if needed. These experts understand the electrical and mechanical details of the work that they do and will make sure that your product is built correctly.

Components: With their vast networks of component manufacturers and vendors, local PCB CMs will have access to the parts you need for your project. Plus their ability to review the parts that you are using in your design may result in suggestions for replacement parts that have better performance, prices, or lead times.

Speed: Local PCB CMs are specialized in low-volume high-mix production, which means that they are used to manufacturing many different types of projects quickly. This puts them into the position to respond quickly to your needs and requirements while developing a superior product for you.

Industry Category