How are PCB assembled?

By:PCBBUY 06/21/2021 18:01

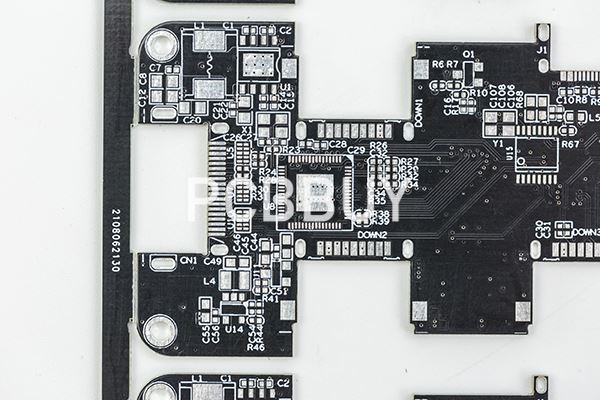

Since SMT assembly is a pretty important part among all the PCB manufacturing process, it will also affect the performance and the finished products of PCB. So due to the high-density nature of PCBs, the components of boards are very small so that the risks of defects will rise.

In this passage, we will focus on the essential factors of PCB assembly and please follow us to learn more PCB professional knowledge.

What is the whole process of PCB assembly?

1. During the design phase

The actual process of SMT starts in the design phase. If you want to keep your production hassle-free, you will have design accordingly. There are many considerations for a good PCB SMT design. You need to consider the size, thickness, and other aspects of the PCB board. Only then can you choose the right components.

While designing, you should try to reduce as many components as possible. Unnecessary clutter can compromise the quality of the PCB. It can also increase the cost of SMT assembly and PCB production.

Other things to consider include the lead length of SMT components. You need to have an adequate exposed point to make your solder joints. The design phase should take into account all considerations of SMT assembly.

2. Design for Manufacturing and Assembly

PCB manufacturers should follow DFMA or Design For Manufacture and Assembly practices. DFMA helps manufacturers create the best quality PCBs with SMT assembly. The process also reduces the cost and chances of making mistakes. You can also produce more batches in less time for agile marketing. DFMA has several considerations when it comes to SMT. You need to have the right via positions, panel design, right component positions, and more.

Adopting DFMA principles makes way for accurate PCBs that don't need changes later on. DFMA improves PCB manufacturing efficiency to a great extent. It's best if you do the DFMA and then hand the design to the PCB manufacturer.

Else, it would help if you chose a reliable PCB manufacturer like us.

3. Ensuring the Format

PCB designers need to finalize the components and plans. Only then they can send the data and design to the manufacturer. The designer has to ensure the right size to facilitate automation. The format of the design should match the requirements of the manufacturer. Otherwise, you may have problems during the SMT assembly.

PCB designers should also run DFM checks before sending the data to manufacturers. DFM checks help identify issues in design, like missing parts and wrong measurements. Running DFM checks at this stage reduces the risks of scrapped PCBs.

4. Choose Gerber Data

For bare PCB manufacturing, Gerber data is always available. But it can be a bit time-consuming. The effort is worth it, as all manufacturers support Gerber files. You can convert your PCB SMT assembly design to Gerber format. Then you can send it to your PCB manufacturer.

Gerber format is the standard for PCB design and manufacturing. The file consists of an ASCII text file that integrates four elements into it-

·Parameters for configurations

·Definitions of apertures

·XY coordinate placements for flash and draw commands

·Command codes for flash and draw

PCB manufacturers can directly work with Gerber data and start producing your PCBs. It saves time and helps the manufacturer complete your batch quickly.

5. Solder Paste Printer

The solder paste machine is the first machine in the manufacturing process. Using a stencil, it applies solder paste to the required PCB pads. Manufacturers first put solder paste on the PCB. They use a stainless steel stencil to isolate places to apply solder paste. The components in the SMT assembly will sit in these areas.

The solder paste in the printer contains small metal balls. Flux helps the solder melt and stick with the surface of the PCB. Most manufacturers use a machine or solder printer. The tool applies solder paste in chosen areas in the right amount. The device then applies the solder on the whole stencil. As a result, all open areas get soldered for SMT assembly.

Soldering is an essential step for accurate placing of SMT devices. The components will rest on the soldered areas and then fixed via reflow soldering.

6. Carrying Out Inspections

The inspection machine within the solder paste printer is an excellent way to carry out inspection. It may be, however, a bit time-consuming. You can opt for a dedicated inspection machine that uses 3D technology.

The inspection is essential and checks the quality of the soldering. The SMT assembly process can only move forward once the verification is over. Engineers sometimes also check the boards manually, especially in the case of prototypes. If there are issues in soldering, you should address them immediately.

7. Take Care of Component Placement

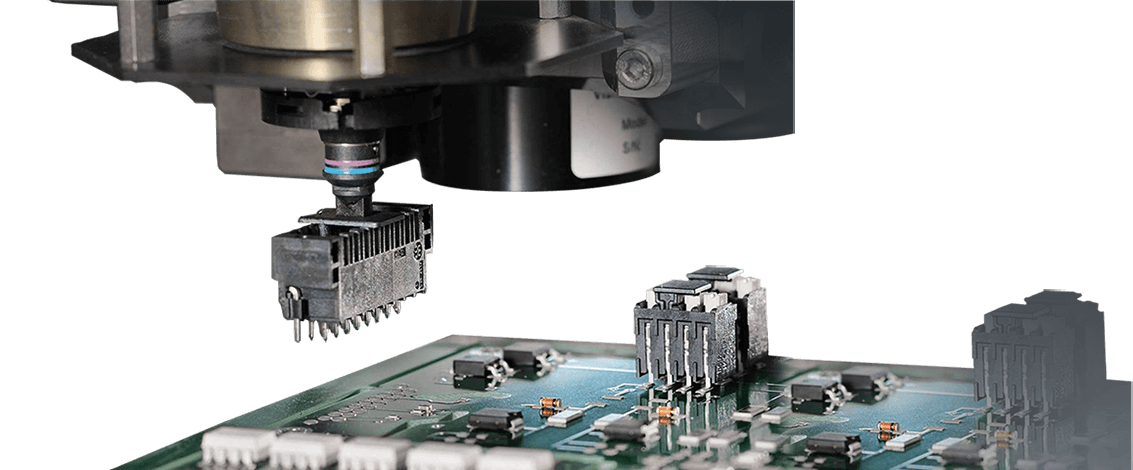

Component placement is the most crucial step of SMT assembly. Here engineers place the components on the solder on the PCB. Earlier, companies used old-fashioned ways to place elements on PCBs. Now, advanced technology gives us machines to perform the task.

Reliable PCB manufacturers use machines that can pick and place components. The process saves ample labor hours for the manufacturer and takes the help of automation.

8. Correct Reflow Soldering

The reflow soldering attaches the components on the PCB permanently. The PCBs move through an industrial oven at very high temperatures. The heat melts the solder paste, which runs around the placed components. The PCBs then move through a conveyor belt through coolers. Solidifies the solder paste and fixes the components in their places efficiently.

Two-sided PCBs need a bit more work for reflow soldering. It would help if you did it on both sides using the stencil placement method. Manufacturers first reflow the team with fewer components. Then they attend to the other side of the PCB.

A correct reflow profile is vital to guarantee that there is no damage. It finds discrepancies in the parts due to overheating and disqualified solder joints.

Industry Category