How to Apply Conformal Coating on PCB with 5 Essential Tips?

By:PCBBUY 11/05/2021 10:07

In this article, you’ll be given all the information that you need to identify the ideal conformal coating for your application’s requirements. If you are searching for something specific, feel free to use the index for a more selective approach. Otherwise, this article is helpful both for beginners who seek to understand conformal coating methodology and use.

And for seasoned applicators and businesses who wish to confirm their knowledge-base and procedural legitimacy. You can also check out our selection of conformal coatings here. If you are interested in PCB conformal coatings, please check and read the content below.

If you want to order PCB product, please check and custom your order online.

1. What are types of PCB conformal coating?

Coatings are categorized by their base resin:

Acrylic Resin (AR) – AR coatings are relatively economical, provide good overall protection, and are easy to apply and repair. They have high dielectric strength, and fair moisture and abrasion resistance. Acrylic coatings are easily and quickly removed by a variety of solvents, often without the need of agitation. This makes rework and even field repair both practical and economical. That being said, acrylic coatings are not effective at protecting against solvents and solvent vapors, like jet fuel fumes common in aerospace applications.

Konform AR Acrylic Conformal Coating is easy to use, offers great protective properties, and is both IPC-CC-830B and UL certified.

Silicone Resin (SR) – Silicone conformal coating provides excellent protection in a very wide temperature range. SR provides good chemical resistance, moisture and salt spray resistance, and is very flexible. Silicone conformal coating is not abrasion resistant because of its rubbery nature, but that property makes it resilient against vibrational stresses. Silicone coatings are commonly used in high humidity environments for applications such as outdoor signage. Removal can be challenging, requiring specialized solvents, long soak time, and agitation from a brush or an ultrasonic bath.

Urethane (Polyurethane) Resin (UR) – Urethane conformal coatings are known for their excellent moisture and chemical resistance. They are both abrasion-resistant and solvent-resistant, which results in coatings that are very difficult to remove. Like silicone, full removal generally requires specialized solvents, long soak time, and agitation from a brush or an ultrasonic bath. Urethane conformal coatings are commonly specified for aerospace applications where exposure to fuel vapors is a common concern. Chemtronics does not offer any urethane coatings.

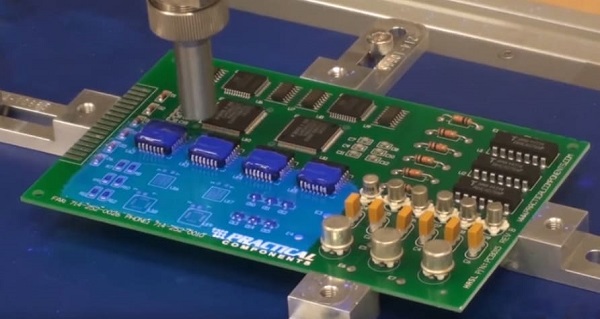

2. How apply PCB conformal coatings?

The application of a conformal coating using a brush is a common practice. This is a simple process but requires a skilled operator for ensuring the proper quality and finish of the coating. It requires a brush, a container for storing the coating, and a defined area for the application. The brush is dipped in the coating material and applied to the board.

The factors affecting the brushing method quality are the type of brush, operator skill, viscosity of the coating, the environment, and the coating material. It offers some advantages such as low setup, simplicity, and fewer process control requirements. This method is suitable for low-volume production and rework.

3. What are the technologies of PCB conformal coatings?

· Brush - The brushing method is an easy technique used primarily for repair and rework. There is a low cost associated with the brush method however it is labour intensive. With brush application it can be difficult to control the coating thickness, but is still viable and applicable for smaller production runs. Applying coatings by brush is most often done after repairs.

· Dip - Dipping consists of most or all of the PCB being "dipped" or immersed into a conformal coating. It is a technique commonly used for high-volume productions and when both sides of the circuit board can be coated. Dipping can coat many PCBs at one time but requires significant masking.

· Spray - Spraying can be applied manually or automated.

Aerosol cans or a handheld air brush type spray gun are two manual techniques typically used for low-volume production. Because of the nature of this application, areas that don't need coating must be masked. The masking process can become labour intensive. Manually sprayed components usually require multiple applications.

4. Why PCB conformal coatings are important?

Moisture

Moisture is the commonest and destructive factor causing damage to PCB boards. Too much moisture will dramatically decrease insulation resistance and the value of Q, accelerate high-speed decomposition, and get conductors eroded. It's common for us to see metal parts that have been assembled on PCB board is covered with a layer of green copper just because chemical action just takes place between copper and water vapor and oxygen.

Pollutant

It's hardly believe that hundreds of pollutants can be found on the surface of printed circuit boards when conformal coating isn't applied on them. Those pollutants are equivalently hazardous to the reliability and functionality of PCBs. Similar with moisture or high humidity, pollutants contaminated on circuit boards can also lead to bad results such as electronic failure, conductor erosion, or even irretrievable shortcuts. Majority of contaminants left on circuit boards derive from residues during manufacturing process including flux, solvent parting agent, clipped wire and marking ink. Moreover, some contaminants result from manual residue when boards are touched by operating people including human oil, finger print, cosmetics and food residue. Plus, lots of pollutants even come from operating environment, such as salt spray, sand soil, fuel, acid and other erosive vapor and mould.

5. What are the advantages of PCB conformal coatings?

· Insulating properties allow a reduction in PCB conductor spacing of over 80%

· Can help eliminate the need for complex, sophisticated enclosures

· Light weight

· Completely protect the assembly against chemical and corrosive attack

· Eliminate potential performance degradation due to environmental hazards

· Minimize environmental stress on a PCB assembly

Industry Category