How to Avoid BGA PCB Defects?

By:PCBBUY 03/26/2024 15:45

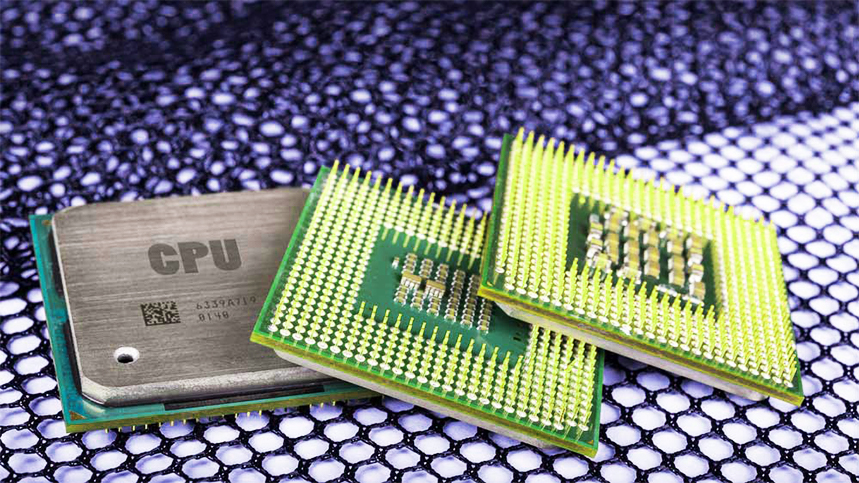

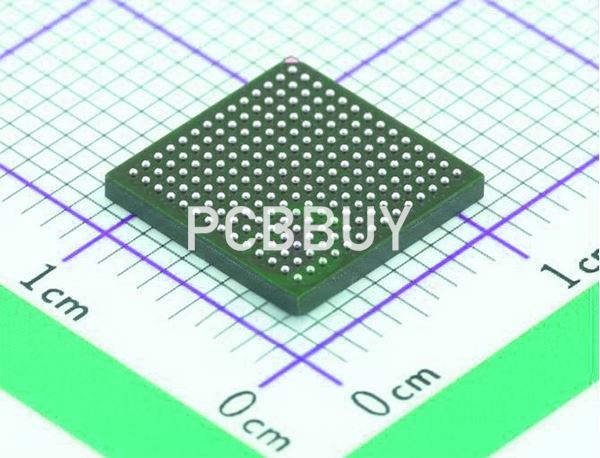

BGA chips win over QFP (quad flat package) chips in terms of the shape of BGA packages. BGA packages make the physical size of chips dramatically reduced with solder ball array replacing peripheral leads at QFP chips, which is especially obvious when multiple I/O pins are available. The surface area of BGA linearly increases with the improvement of I/O pin count while that of QFP increases with the improvement of I/O pin count square. As a result, BGA package provides more manufacturability to components with multiple pins than QFP.

Are you going to learn more about details of BGA PCB layout? If you are searching for BGA PCB layout, you can check and read the content below for more knowledge in this passage.

How to Avoid BGA PCB Defects?

During the process from lead PCB manufacturing to lead-free manufacturing, reflow soldering and wave soldering temperature has to rise up due to SMT (surface mount technology) assembly requirement. Some people simply believe it OK that substrate material with high Tg (glass transition temperature) is selected for PCB board. They just think that it's essential to manage and control Z-axis expansion.

The primary aim is to stop delamination from taking place of thick circuit boards and 14-layer or more PCBs and to stop cracks from occurring to PTH (plated through hole) because a large extent of Z-axis expansion of PCB tends to lead PTH hole wall to break during reflow or wave soldering. Nevertheless, Tg fails to defeat cracks generated during lead free process unless Td (temperature of de-composition) is considered to totally solve PCB cracks issue. Three levels of Td are regulated in IPC concerning PCB substrate material: 310°C, 325°C and 340°C.

What are the features of BGA?

· More I/O. Since BGA encapsulated solder balls are arranged under the encapsulated substrate in the form of array, the number of I/O of the device is greatly increased, the size of the encapsulation body is reduced, and the space od assembly is saved.

· High packaging yield reduces cost.

· The contact surface between BGA’s array welding ball and substrate is large and short, which is conducive heat dissipation.

· The pin of BGA array welding ball is short, which shortens the signal transmission path, reduces the lead inductance, electrical resistance and improves the circuit performance.

· Improve the coplanability of I/O terminal and reduce the loss caused by poor coplanability in the assembly process.

· BGA is suitable for MCM encapsulation and can achieve high density and high performance of MCM.

· The IC of BGA and fpBGA is stronger and more reliable than the foot-shaped package of detail spacing.

·

How to process the BGA PCB layout control?

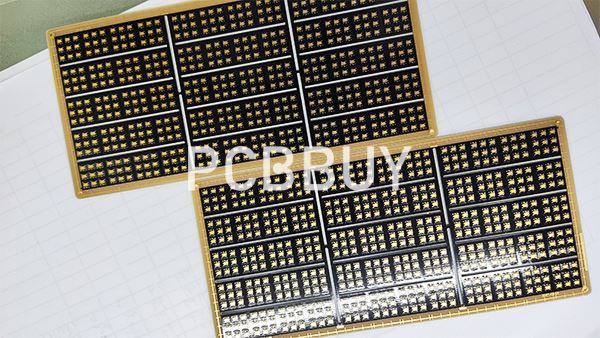

· During stencil design phase, four corners and each side of BGA component should be 1mil to 2mil larger than those of pad. Stencil opening size should be designed based on specs of BGA components including pitch, soldering balls on BGA and ingredient of soldering balls.

· During the process of printing, support pin shouldn't be against BGA to stop fake soldering and pillow effect from taking place due to contamination of BGA pad. Furthermore, especially much attention has to be paid to printing scraper pressure and printing quality control.

· Wafer positions of pickup BGA, component thickness setting and pressure amount of pickup should be emphasized during mounting stage.

· There are more opportunities for cracks during IR reflow and special attention has to be paid:

What are the reasons of BGA soldering defects?

Incorrectly-Picked Tg and Td of PCB Substrate Material

During the process from lead manufacturing to lead-free manufacturing, reflow soldering and wave soldering temperature has to rise up due to SMT (surface mount technology) assembly requirement. Some people simply believe it OK that substrate material with high Tg (glass transition temperature) is selected for PCB board. They just think that it's essential to manage and control Z-axis expansion. The primary aim is to stop delamination from taking place of thick circuit boards and 14-layer or more PCBs and to stop cracks from occurring to PTH (plated through hole) because a large extent of Z-axis expansion of PCB tends to lead PTH hole wall to break during reflow or wave soldering. Nevertheless, Tg fails to defeat cracks generated during lead free process unless Td (temperature of de-composition) is considered to totally solve PCB cracks issue. Three levels of Td are regulated in IPC concerning PCB substrate material: 310°C, 325°C and 340°C.

In conclusion, during the process of substrate material determination, the higher Tg and Td are, the better. But PCB fabrication cost is an essential consideration based on which substrate material with agreeable Tg and Td should be picked up.

Insufficient Gel Content in Prepreg

Insufficient gel content in prepreg used on external layers and between internal layers tends to lead copper foil to generate bubbles under high temperature.

Unsuitable Copper Profile Selection

Generally, ordinary profile is classified into three categories: standard profile, lower profile and very lower profile. Standard profiles contain no regulations on copper sheet because adhesiveness is high but too high profile tends to cause bad etching, which further reduces stability of line width and impedance control. Lower profile regulates that maximum Profile SPEC is 0.4mil (10.2μm). Up to now, lower profile has been leveraged by most PCB manufacturers. Very lower profile regulates that maximum Profile SPEC is 0.2mil (5.1μm), which is generally only leveraged in multilayer PCB fabrication with special fine line requirement such as 2mil trace width.

Industry Category