How to Check PCB Soldering through 5 Effective Aspects?

By:PCBBUY 10/19/2021 09:39

The PCB industry urgently needs online automatic visual inspection, and foreign products are too expensive. Based on this situation, the country began to develop this detection system. This paper mainly studies the identification of soldering defects on PCB boards: identification of color ring resistance, identification of electronic component leakage soldering and identification of capacitor polarity.

And if you are going to learn more information about PCB soldering process, please check and read the content for more professional knowledge.

1. What are the common defects during PCB soldering?

Soldering PCB Board—Pinhole

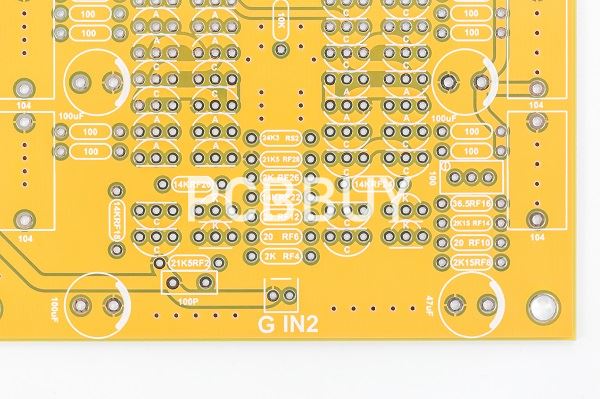

A pinhole or blowhole is a small hole formed in a joint soldered on PCB to mount a component using through-hole technology. We can use the term pin and blow interchangeably; however, it is common to use a pinhole to indicate a smaller hole size. You can identify pinholes or blowholes by the thick copper plating formed during the process.

Solder bridging

Solder bridging is one of the most challenging soldering defects to discover because we can’t recognize it by the naked eye. Solder bridging form short circuits, which can lead to serious harm to the PCB circuit. This type of error occurs when soldering crosses mistakenly connect two leads.

Tombstoning

Tombstone refers to a soldering defect when one of the component terminals fails to stay attached to the board while the other stays coupled to the board. Small components are more likely to have this issue during the soldering reflow procedure.

Overheated joints

You may come across overheated joints when the heating process cannot melt the soldering wire, leading to overheated flux on the pad. It is hard for us to repair this defect because of the overheated change.

2. How to determine verification of PCB soldering?

High reliability assembled PCB prototypes as well as novel surface mounted devices (SMD) and mixed systems must be assessed according to well defined qualification test plans. Such high reliability verification programmes are not limited to just evaluate the robustness, reliability and performance of the product but they also address the verification of tools, fabrication procedures and involved materials, as well as the confirmation of product integrity. For instance, “European Cooperation for Space Standardization” (ECSS) standards used in space programs

ECSS-Q-ST 70-38C “High-reliability soldering for surface mount and mixed technology”

ECSS-Q-ST 70-08C “Manual soldering of high-reliability electrical connections”

3. What are the features of soldering finished PCB?

Although it is possible for anyone to throw down solder onto PCBs, whether you get classy solder joints or downright caveman quality ones is a different matter altogether. With components becoming smaller and more compact, the chances of soldering issues occurring have become higher. When soldering the PCB, try to make the finished product have the following characteristics:

· The soldering surface is kept clean;

· The solder joints must have sufficient mechanical strength to prevent the soldered parts from falling off or loose under vibration or impact;

· The soldering must be reliable and ensure electrical conductivity This is not only a guarantee for the product’s function but also to prevent the product from being burned out by a short circuit.

4. Is the PCB soldering necessary for all the products?

Solderability testing helps determine if a component provides the degree of wetting necessary for a solid solder connection. A poor test result indicates a less-than-optimal connection. Without this testing, you may have to rework the connections.

Solderability testing is effective during different aspects of production, such as when:

· Evaluating PCB coating, solder, and flux

· Benchmarking

· Performing quality control

5. What are the steps of PCB soldering checking?

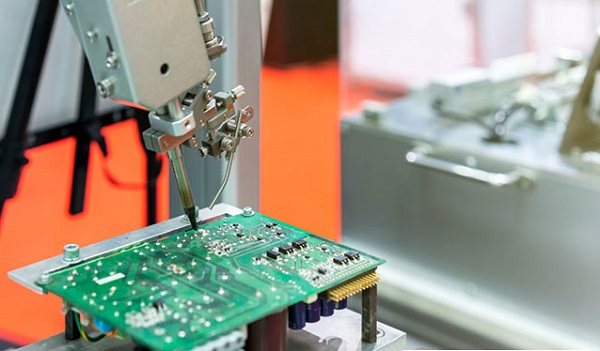

Today, the most common type of solder is lead-free (Sn-Cu) rosin core solder. Unless your assembler is working a one-off board or you are assembling your own board, the PCBA will not be soldered by hand. Instead, it will go through an automated process:

· Wave soldering: Used for through-hole components

· Reflow soldering: Used for SMT components in a reflow oven

· Selective soldering: Used when a through-hole component might be damaged by high heat or is unsuitable for the wave and reflow processes

Industry Category