How to Choose A PCB Manufacturer to Guarantee the Board Quality?

By:PCBBUY 03/04/2022 10:27

The first question to ask is whether the PCB manufacturer can work to the required specifications. In essence can they accept the files on the formats they will be provided (normally this should not be a problem as formats are generally standard), and also produce a board of the required specification: number of layers, type of PCB material; tolerances; specific requests, etc.

In this passage, we will provide you all the information to learn more about choosing a PCB manufacturer. If you are searching for the information about the methods of choosing a PCB manufacturer, please check and read the content below.

What is the importance of choosing a PCB manufacturer?

This is by no means an attempt to provide a comprehensive list of fab houses that you might want to use for a low-quantity order; that information is readily available via Google. Instead, I want to offer some suggestions based on my knowledge and experience. I’m not going to comment on the quality of the boards produced by a given manufacturer because I’ve never in my life received a PCB that I would describe as poorly manufactured (I don’t know if this is because I’m lucky or because I have a knack for identifying fab houses that are serious about quality). I think it’s safe to assume that all of the following fab houses will deliver a fully functional PCB.

What is a professional PCB assembly manufacturer?

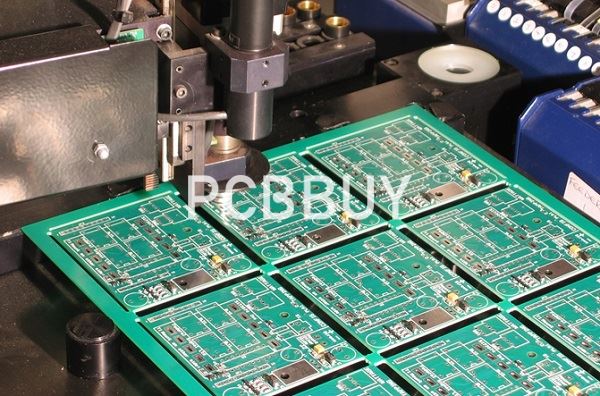

The primary obstacle here is cost. Automated assembly technology is mature and highly reliable, but the process is not economically adapted to low-quantity orders. It also requires additional manufacturing data:

BOM information: The assembly house needs information that enables them to either order the parts or organize the parts that you provide.

Solder mask: You need to submit Gerber files that identify the areas of the board (e.g., pads for IC pins) that must receive solder during the process of solder-paste deposition. (Solder paste is the type of solder used in reflow assembly.) This can be a bit complicated because in some cases you need to create solder-mask divisions that divide one large pad into multiple smaller rectangles of solder paste (see this article for more information).

Placement data: This includes spatial coordinates and rotation for every part on the board. The machine cannot place components if it doesn’t know which ones go where and how they are oriented.

In some cases you might decide that assembling the board yourself is less trouble than generating and double-checking all this extra information.

I know of only one company (MacroFab) that can perform low-quantity automated assembly at a reasonable cost. If you’ve found any other way to obtain similar services at a similar price, please let us know in the comments.

Which part is important to choose a PCB manufacturer?

While the large assembly plants overseas are recovering from the effects of the pandemic, there are still many concerns for designers when choosing them as an assembly partner. Tariffs, shipping schedules and costs, and labor problems all must be considered. On the other hand, a local PCB CM can sidestep these issues and give you high-quality service in less time. However, it is still essential to review their attributes before you make a choice. Here are some areas of inquiry:

Engineering: Getting a prototype or NPI project off the ground quickly and successfully often requires the engineering services of the PCB CM. They need to be knowledgeable and experienced in all aspects of PCB design and manufacturing to provide you with the help you need.

Procurement: Working within the confines and restrictions of the current supply chain is highly challenging. Your PCB CM should have a procurement team with a well-developed network of vendors and the experience to work around the different pitfalls in the supply chain.

Manufacturing: You need a manufacturing partner to quickly adapt to your production needs to help you meet your goals. These can include prototypes, NPI development, limited production runs, engineering changes, or low-volume production.

Box build capabilities: If you are looking at developing a new product quickly, you will want to reduce the number of vendors to manage and coordinate. Choosing a PCB CM with full box build capabilities will give you all of these services under one roof saving your time, expense, and resources.

With questions like these, you can narrow your choice of PCB circuit board assembly partners down pretty quickly, and the answer may be closer than you realize.

Choose PCB manufacturer like PCBBUY

PCBBUY Technology Co. Ltd is a smart factory specialized in quick turn PCB prototyping. PCBBUY service center is located in the beautiful city - Hangzhou, China, and its factory is located in the southern gate of China - Zhuhai, Guangdong. There are production lines of Single PCB,2 layers PCB,4 layers PCB,6 layers PCB,8 layers PCB and 1000mm PCB. We has passed the SGS, RoHS, UL and other authority certification, the fastest can achieve 24 hours of delivery.

Industry Category