How to Choose PCB Manufacturer with 7 Common Questions?

By:PCBBUY 09/26/2021 09:51

Choosing a right PCB manufacturer is very important to all the customers. It’s much more reliable and simpler to go the professional route and to collaborate with a PCB manufacturer that can bring your design to life. Some PCB manufacturers work well for individual inventors and small businesses. Making the best choice can save you time, money, and make sure that you don’t end up with a faulty product.

How to choosing the manufacturer to produce our PCB? If you are going to learn all the detailed information about manufacturer choosing, please check and read the content for more knowledge about it.

What are the 7 common questions to choose PCB manufacturer?

1. How to know the PCB manufacturer is experienced?

Maybe you need to craft high-tech PCBs in a limited time frame. Perhaps you have to meet specific board material standards. Regardless of your situation, you need to know you’re working with a knowledgeable partner that can back up its quickturn promises.

Not all PCB fabrication and manufacturing professionals specialize in quickturn. Don’t be afraid to ask for specific figures regarding on-time delivery, as well as the percentage of circuit boards manufactured within tight turnaround times. Ask how different layers, board types and lead times will affect delivery.

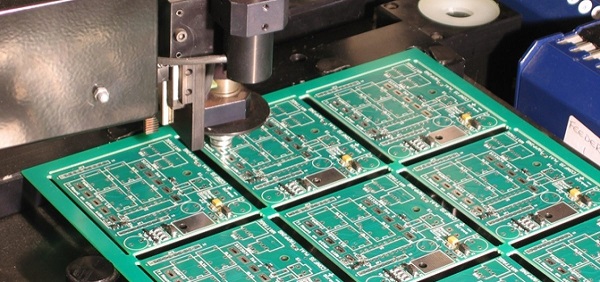

2. What is the producing process of the PCB manufacturer?

Much of the difference between efficiency and effectiveness involves process control. The processes defined by a PCB manufacturer must align with the decisions that your team makes about the board layout, shape, type, materials, and components, and all of this impacts the sub-processes that make up each stage of the larger manufacturing process.

In addition, those processes must match the design specifications for precision and accuracy. Along with other processes, a manufacturer must have the ability to create correct positive and negative images, maintain the alignment of layers within multilayer boards, etch inner and outer layers, drill precise vias and mounting holes, and apply the optimal finishes.

3. What are the successful cases of the PCB manufacturer?

You wouldn’t hire an employee without checking their references, so why make that mistake with a PCB partner? Quality board shops will be proud of their work and happy to point you toward satisfied customers, whether in person or in the form of a case study. Examine company websites to see if case studies are featured prominently. If you don’t find any, ask for examples. These types of assets should provide details on the individuals and businesses that have worked with the board shop in the past, as well as how their services helped achieve quick turnaround times.

4. How to determine the timeline of the PCB manufacturer?

You probably want the process of choosing a PCB assembly company to go as quickly as possible so you can keep your project moving, get your product to customers and maximize profit while minimizing expenses. Rushing through this critical step can result in more time wasted than time gained in the long run, though. Take as much time as you need to get a full understanding of what a company offers before committing to partnering with them. That said, don’t let a company that is slow to respond to your questions hinder your progress. If getting the information you need, such as a quote, requires reaching out to a company multiple times to check on its status or requires an extensive back-and-forth that seems unnecessary, you may need to look elsewhere.

5. What are the options for testing of the PCB manufacturer?

Testing services should be part of what a PCB assembler offers any time they do a project with you. Adequate quality testing is crucial because a failure can cost you time and money and cause damage to your reputation. Before signing up to partner with a company, ask about their testing options. Look for companies that have comprehensive testing procedures and company-wide quality control processes. They should offer visual inspections as well as more involved testing options. A willingness to work with you to develop a custom testing plan is a huge plus. Some of the testing services companies might perform include automated optical inspections, component-level checks and in-circuit verification.

6. How to process the quality control of the PCB manufacturer?

Choosing a PCB Assembly services company that provides in-house design and assembly process review can help enormously with quality control. It also helps speed up delivery times. Make sure you know how the company tests for quality. Do they have up-to-date machinery and technology? Do their employees consistently produce a high standard of product?

7. How to make sure the IPC standard of the PCB manufacturer?

Compliance with the ISO 8402 standard assures design teams that a manufacturer has the capability to trace any problems encountered with a board to a root cause. The ability to trace—or traceability—shows that a manufacturer can successfully check production processes, supply chain issues, or maintenance problems. Questions about traceability can cover processes such as the assignment of lot codes for materials arriving from the supply chain, the type of equipment used to perform chemical solution checks, and the assignment of lot and date codes to completed PCBs.

PCB manufacturers should also demonstrate compliance with IPC standards. Those standards cover all classes and types of boards and establish performance and quality levels. The IPC standards also describe quality expectations for the supply chain and the capability of manufacturers to source and trace critical components.

Choose PCB manufacturer like PCBBUY

PCBBUY Technology Co. Ltd is a smart factory specialized in quick turn PCB prototyping. PCBBUY service center is located in the beautiful city - Hangzhou, China, and its factory is located in the southern gate of China - Zhuhai, Guangdong. There are production lines of Single PCB,2 layers PCB,4 layers PCB,6 layers PCB,8 layers PCB and 1000mm PCB. We has passed the SGS, RoHS, UL and other authority certification, the fastest can achieve 24 hours of delivery.

Industry Category