How to Clean Corrosion off PCB through 5 Effective Methods?

By:PCBBUY 11/05/2021 09:37

PCB can be found in some form inside all of our electronic devices. Despite our best efforts, these devices can get wet. Whether is if from spills to the occasional dunk in the sink, the outside casing is not the only part of the machine that can be affected. If water or any other liquid gets inside the device, it can reach the circuit boards and cause the device to stop working. Cleaning the board can sometimes restore functionality once the board is dry.

Are you curious about the methods about cleaning the PCB corrosion? If you are interested in the topic, please check and read the content below for more.

How to determine the types of PCB corrosion?

· Atmospheric: This is the most standard type of corrosion. Metal is exposed to moisture, which contains oxygen, causing a reaction where the metal ions bond with the oxygen atoms and create an oxide. Copper experiences atmospheric corrosion very easily, which is not a problem for copper plumbing because corroded copper retains its mechanical properties. It does not, however, retain its electrical conductivity, so this is a big problem for circuit boards.

· Galvanic: Galvanic corrosion occurs when different types of metals are in the presence of an electrolyte. In these circumstances, the more resistant metal will actually corrode faster than the baser metal it’s in contact with, so when gold is in contact with tin, for example, the gold will corrode much faster than usual.

· Electrolytic: In this type of metal degradation, adjacent traces experience dendrite growth when ionic contaminated moisture infects the electrical voltage between them, creating metal slivers that result in a short circuit.

· Fretting: With fretting corrosion, the action of closing solder-plated switches creates a wiping action that removes the surface oxide layer, allowing the layer beneath to oxidize. Eventually, excessive rust builds up and prevents the switch from activating.

What are the causes of PCB corrosion?

Circuit boards are found in nearly all electrical devices, including computers and industrial equipment. Over time, water, dust and grime can find their way into your company’s devices and build up to a point where you must take action to prevent permanent damage to the equipment.

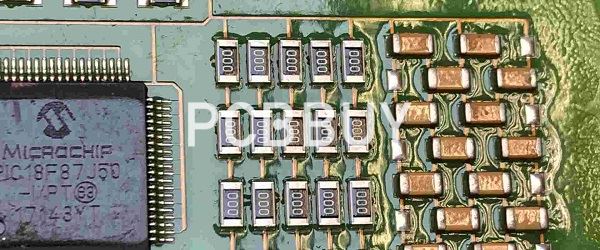

Circuit boards found in devices

The fans responsible for keeping equipment’s temperature at a cool environment suitable for proper functionality can draw in debris found in the air and any dirt clinging to nearby surfaces. The build-up of unwanted material leads to overheating and component failure.

Once a liquid with good conductive qualities contacts an active device, electrical connections travel through currents to deactivated regions of the circuit board that can lead to short-circuiting. This harms a circuit and damages your device.

What are the 5 effective methods to remove the PCB corrosion?

There are two ways to clean a corroded circuit board: Using a solution mixed with alcohol, baking soda, and water. The other is using a special circuit board cleaning spray.

1. Always remove the device’s batteries and power source first. This will not only prevent short-circuiting, but will prevent you from being injured. Please note that you may be exposing other elements of the device to possible corrosion, so do this carefully.

2. Corrosion can be found if you see a white or greenish substance that looks and feels “crusty”. Common places to look include charging ports, battery connectors, SIM card connectors, and any mechanisms that allow you to connect wired accessories to the device.

3. Use cotton swabs or Q-Tips. Also use isopropyl alcohol, baking soda and water to clean corrosion. You can also use vinegar. Gently apply the mixed solution to the affected area and wipe back and forth until the corrosion is gone. You can even apply the solution on the corroded area and let it sit for an extended period of time before wiping it off.

4. To dry the device, use a hair dryer on the cool setting or a soft cloth. You should never use heat as a way to dry off a device. Before replacing batteries or turning the device on, make sure the circuit board is completely dry.

5. Replace damaged batteries with a new one. Recycle the old batteries properly. Do not dispose them along with any general trash as it may cause damage to the environment.

What are the tools to process to remove the PCB corrosion?

Baking Soda

You can use baking soda to clear corrosions from your PCB. These corrosions result from exposure to salty water and acidic leakages. The mildly abrasive nature of the soda removes the corrosions without causing any side effects.

Isopropyl Alcohol

Isopropyl alcohol is an excellent circuit cleaner tool because it is cheap and evaporates quickly. Besides, the drink contains fewer chemicals, unlike other PCB cleaners. Highly concentrated isopropyl alcohol (above 90%) can damage your skin; hence, always wear gloves when handling it.

Distilled or Deionized Water

Many people prefer distilled/deionized water to hard water because it lacks ions that conduct electric current; therefore, it will not degrade your circuit board. Ensure that your water bottle is closed when not used to avoid contaminating dirt and dust particles in the air.

Compressed Air

Compressed air is a non-disruptive method of clearing dust accumulated on surfaces and within electronics—leverage short bursts to blow air inside your gadget through the open spaces of your device. If the openings are small, you can open your equipment and carefully clean your board with the compressed air.

Industry Category