How to Connect Components to Blank PCB Board?

By:PCBBUY 03/11/2024 15:16

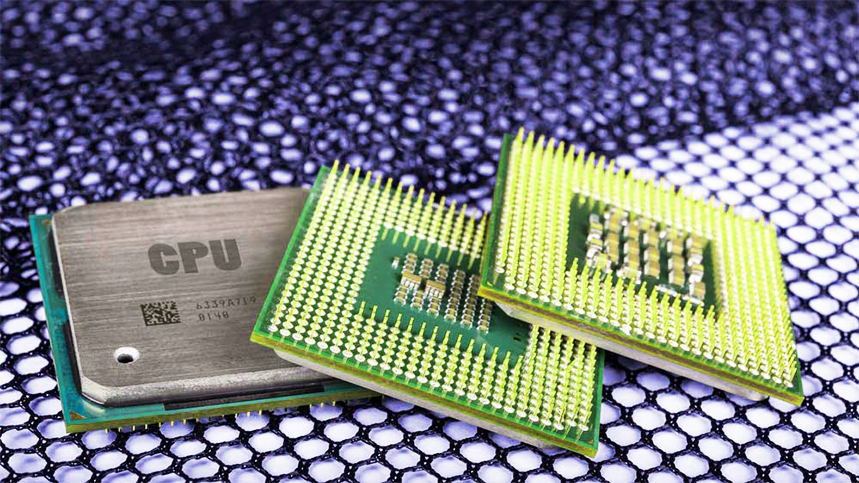

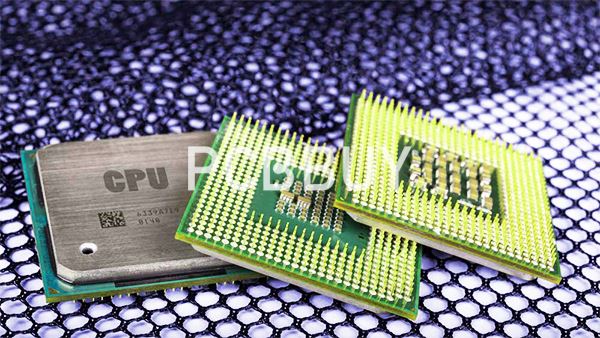

It is called a blank PCB board because there is a layer of copper plating around it. Let us not neglect this layer of copper plating. This is a distinctive feature of blank circuit boards. Abstract To put it simply, a blank PCB board is an empty circuit board free from any contacts as well as devoid of pieces that are used and installed in the creation of actual circuit boards.

If you are curious about the methods of using the blank PCB board, please check and read the content below for more professional knowledge.

Why we use blank PCB board?

Blank printed pcb boards have only primary channels, patterns, copper coatings, and circuit substrates. The design of the empty circuit board is straightforward. Engineers and designers are free to add components as needed. This blank circuit board provides flexibility and enables mass production. So blank PCB board are very popular in our daily live.

Compared with other circuit board wiring methods, blank circuit boards require more design work. However, after the empty circuit board is assembled and manufactured, it can often automate. This makes a blank circuit board the cheapest and most effective option.

Use a blank circuit board after adding components. The blank circuit board eventually becomes a complete blank PCB board. If matched with the right ingredients, it will have multiple uses. Therefore, blank circuit boards have greater flexibility than single-sided circuit boards, double-sided circuit boards, and provide flexibility.

How to Connect Components to Blank PCB Board?

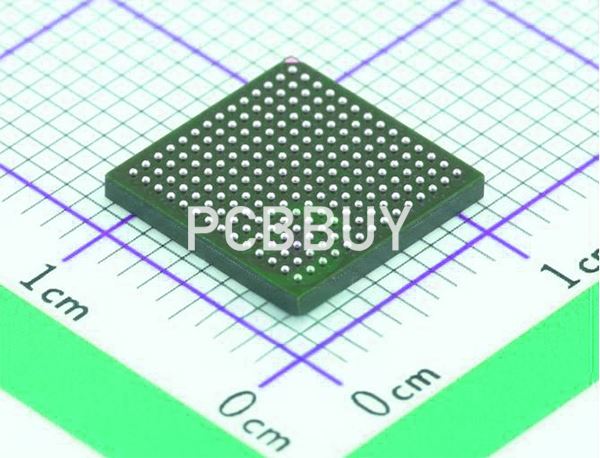

Although connecting components to a PCB board is called mounting technology, the process itself is called soldering. On the flip side, the process of detaching components from a PCB board is called Desoldering. Let's look at these terms in more detail.

Soldering

Soldering is when two or more items are joined together by melting a filler material (solder) between them. Unlike welding, which involves melting the joint pieces, Soldering is a preferable option since the electrical parts won't get destroyed in the joining process.

The solder material is usually a metal alloy with a much lower melting point than the components bonded together. For electrical purposes, it is preferable to use a solder material with high electrical conductivity. A soldering iron is a primary tool to be used for the process. There are complex machines that ensure a high quality of solder connections in electronic circuits for industrial production purposes.

Desoldering

Put, it is the opposite of Soldering. Desoldering is the process of removing solder connections, the solder material, and components from a circuit board for repair, replacement, and salvage. The main instrument used for the process is the desoldering pump. Some additional materials used in the process include heat guns, solder wick, heated soldering tweezers, removal alloys, and removal fluxes.

How to place items onto a blank PCB?

If you do have a case, they will be mounted to that, and you will want to run wires to the board. Make them long enough so you can get your fingers between the board and the case to mount the connectors.

If you are not going to be using a case, it is likely the pins on the audio jacks won't be on 0.1" centers, so you can't just solder them to the board. Get some epoxy and mount the two jacks with the pins sticking out on the sides, and let the epoxy set overnight. Same for the power jack.

Then solder in the LEDs. If you don't have a case, you will want to decide if you want them to be in the center of the board or the elsewhere. If they will be mounted on the top of the case instead of mounting them to the board, you will want to run wires to them. Again, make sure they are long enough to allow you to stick the LEDs in the holes in the case.

How to process blank PCB board milling?

Let’s explain what PCB friction is before we start, so we’ll be all on the same level. Essentially, framing is described as removing the white PCB board of copper portions to produce tracks and designs. All of these structures may be exported from a position power that is a digital file.

While you could ask that etching is easier than milling and the same outcome may be achieved, it is crucial to note that the above fails when making SMDs with a tighter pitch. Milling is frequently your only option in these cases.

Here are a few guidelines that explain why blank PCBs are used for milling.

Have the Proper Mill:

This one is hardly any; you have to get in the correct mill if you’d like to grind your PCB. Whereas the budget of many of these CNC mills may have been absurdly expensive, these costs have collapsed in recent times, and for as about 350-400 USD, you can easily take a mill, and the blank PCB milling costs are minimal.

Select the Right Bits:

Choosing the incorrect bit for a white PCB task is generally the most frequent error among rookie circuit designers. Although all the pieces in your bit case might seem identical, these tiny changes may always let your PCB break or shatter. Therefore, you must examine its size and angular velocity before picking a bit for the milling process. In the absence of this, a printed circuit board with unequal pits and rails will result.

Self-leveling is Key:

Since we talk about unequal fits and paths, the auto-leveling function in your framing program may be easily avoided. It is not very well recognized that regardless of how level a printed circuit board can look to the human eye, all PCB boards are curved. Even though it seems small at first, it’s crucial to note that your mill won’t be able to accomplish your work correctly even if your PCB is completely thinner and you’re left with an unevenly-tracked PCB.

Blank PCB Milling Provides Flexibility:

Only main channels, designs, copper paints, and circuit surfaces have been manufactured blank PCB milling. The layout of the blank circuit board after milling is basic. Designers and engineers may have specific advantages to the PCB milling passenger as required. This white circuit board milling offers versatility and allows bulk manufacture. Blank PCB panels are thus quite popular for milling.

Industry Category