How to Decide PCB Trace Width through 5 PCB Layout Tips?

By:PCBBUY 10/09/2021 09:54

What exactly is trace width and why is specifying a particular trace width so important? The point of a PCB trace is to connect any kind of electrical signal, whether it be analog, digital, or power, from one junction to another. The junction can be the pin of a component, a branch off of a larger trace or plane, or an empty pad or test-point intended for probing. Trace widths are often measured in mils, or thousands of an inch.

If you are going to looking for the methods of how to determine the trace width of PCB, you can check and read the content for more professional knowledge.

How to decide PCB trace width with 5 tips in PCB layout?

1. What are the considerations before determining PCB trace width?

The development of PCB always begins with a default trace width. But such a default trace width is not always suitable for the required PCB. This is because you would need to decide the trace width by considering the current carrying capacity of the trace. PCB trace width can be determined after considering several considerations including:

· Purpose: power trace or signal trace?

· Amperage: or, current, through the trace.

· Location: top or bottom layer, or, inner layer, where heat can’t escape as quickly.

· Thickness: how thick is the copper on the layer?

· Length: how long is the trace?

2. What is the importance of determining PCB trace width?

During the production of PCBs, you may trace a PCB successfully and then later discover that it will not be able to carry the needed amount of current effectively. Consequently, the printed circuit boards intended application experiences a setback. This is due to the inadequate current capacity.

Making use of your PCB trace width calculator ensures the conductance of the right current value. Using this circuit calculator, you may utilize the highest current rating you desire to know the width of your trace. In addition, you may influence the rise in temperature which your PCB records. This is possible by making use of your PCB trace width calculator.

The important factors to consider when selecting a trace width include:

· The current capacity of the trace

· Space availability and manufacturing limitations

· Trace termination

· Impedance

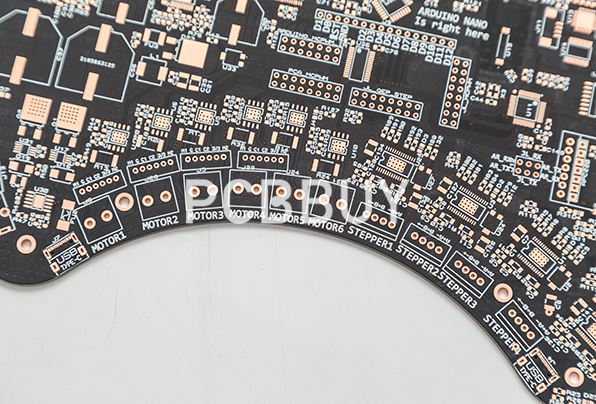

3. How to decide PCB trace width?

Let's walk through the process of calculating for a certain trace width for a power signal delivering current from one power component to a peripheral. In this example, we’ll be calculating the minimum trace width for a power-path used for a DC motor. The power-path starts at a fuse, travels through an H-bridge (a component used to manage power delivery across a DC’s motor windings), and ends at the motor’s connector. The average continuous max current demanded by the DC motor will be around 2 Amps.

Now, a PCB trace acts as a resistor and the longer and narrower the trace, the more resistance is added. If the trace isn’t properly defined, the high current could damage the trace and/or introduce significant voltage drop to the motor (resulting in a slower speed). NetC21_2 shown in Figure 3 is about 0.8” long and needs to carry 2 Amps max. If we assume some general things like a 1-ounce copper pour and ambient room-temperature during normal operation, we have what we need to calculate both the minimum trace width and expected voltage drop at that width.

4. How to use PCB trace width calculator?

Using the PCB trace width calculator is rather simple; all you have to do is follow these steps:

· Select the location of the PCB trace (internal/external).

· Input the trace thickness, maximum current, and maximum temperature rise.

· Obtain your results (PCB trace width and cross-section area).

· Use Advanced mode to reveal some extra options.

· Fill in the length of the trace and ambient temperature.

· Enjoy your extra outputs, like the resistance, temperature, voltage and power dissipation of the trace.

5. How to balance trace impedance for PCB trace width?

This property comes in to play for high speed designs. For signals with high frequency, PCB traces don’t act like a simple connections. Every trace in PCB design has some series inductance, it can be often overlooked in low speed designs but in high speed designs this inductance will likely increase and affect the performance of the board. Adding to that every signal trace holds some capacitance value between the trace and its return path. These factors if left unchecked can deteriorate the performance of PCB since impedance will be different at different points in the PCB.

This calls for a method called as Controlled impedance in PCB designing where the designer should try to keep the impedance constant at every point in the circuit. This article explains the Trace impedance in detail and design considerations for designing controlled impedance PCB.

So these are the few things about trace width that you should consider while designing a PCB. I hope these tips will help you to make better accurate and complicated circuits boards.

Industry Category