How to Define a PCB Stackup with Effective Methods?

By:PCBBUY 05/10/2022 09:43

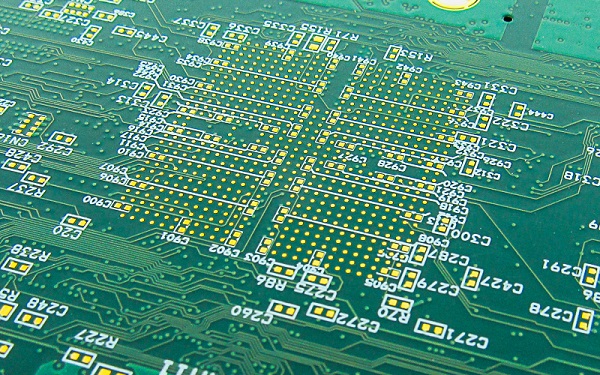

Stack-up describes the construction of a multilayer board in sequential order. It provides vital information like material thickness and copper weights required to fabricate a PCB. Stack-ups are also referred to as build-ups. The stack-up also gives the details of trace width for different controlled impedance traces such as 50ohms, 100ohms differential. An example of a 6-layer stack-up is shown in the above image.

If you are looking for the methods to define the stackup of PCB, please check and read the content in this passage for more professional knowledge.

What is the basic definition of PCB stackup?

A stackup is the arrangement of layers of copper and insulators that make up a PCB before designing the final layout of the board. Managing a good stackup is not exactly easy and companies that make multilayer printed circuits such as Proto-Electronics, a European platform dedicated to the rapid prototyping of SMT printed circuits and cross-section components, for professionals, must be at the forefront.

Having multiple layers (see figure 1) increases the board's ability to distribute energy, reduces cross-interference, eliminates electromagnetic interference and supports high-speed signals. While a stackup level allows you to get multiple electronic circuits on a single board through the various layers of PCB board, the structure of the PCB stackup design provides many other advantages:

· A stack of PCB layers can help minimize the circuit vulnerability to external noise, as well as minimize radiation and decrease impedance and crosstalk problems on high-speed systems;

· Good PCB stacking can also contribute to efficient and low-cost final production;

· A correct stack of PCB layers can improve the electromagnetic compatibility of the project.

What is the standard board thickness of PCB stackup?

The thickness of a PCB mainly depends on factors such as copper thickness, materials used, number of layers, and the operating environment. The standard thickness of a conventional board is around 62 mils (1.57mm). Today, PCBs have become more complex as the copper layer weight and the layer count have increased for various applications. Due to this, the PCBs tend to become thicker. Manufacturers, based on the customer’s request, are now fabricating PCBs with two new standard thicknesses, 93 mils (2.36mm) and 125 mils (3.17mm) (150% and 200% of old standard thickness).

What are the 3 tips for PCB stackup rules?

Determining the layer arrangement

After determining the number the layers, you need to determine how they should be arranged or stacked. Good rules to follow here are:

· Route high-speed on minimum thickness microstrips.

· Place signal layers next to internal power layers for tight coupling.

· Power and ground layers should have minimal spacing between them.

· Avoid having two signal layers adjacent to each other.

· Make the stackup symmetric from the top and bottom layers inward

Determining routing and vias

Completing the PCB stackup design is the determination and routing of the traces. This includes determining copper weights, where to put vias and what type of vias to implement. As for all specifications for your design, you should work with your CM in making these determinations as some CMs avoid certain via types, such as via-in-pads.

Know the advantages of multilayer PCB stackup

Having multiple layers (see figure 1) increases the board's ability to distribute energy, reduces cross-interference, eliminates electromagnetic interference and supports high-speed signals. While a stackup level allows you to get multiple electronic circuits on a single board through the various layers of PCB board, the structure of the PCB stackup design provides many other advantages:

· A stack of PCB layers can help minimize the circuit vulnerability to external noise, as well as minimize radiation and decrease impedance and crosstalk problems on high-speed systems;

· Good PCB stacking can also contribute to efficient and low-cost final production;

· A correct stack of PCB layers can improve the electromagnetic compatibility of the project.

What is the perspective of PCB stackup?

Regardless of the number of layers that comprise your board design, specifications for pad spacing, clearances, trace widths, copper weights and drill hole sizes must be tailored to your contract manufacturer (CM). If your design requires multiple layers, you will need to consider additional design for manufacturing (DFM) specifications for signal, power and ground routing through vias, as well as the PCB stackup. These additions entail incorporating verticality into your design perspective.

Industry Category