How to Design PCB Board through 5 Key Design Rules?

By:PCBBUY 10/22/2021 09:18

PCB design tools have design rules and constraint management systems built into them, and as we tell our kids, the rules are there to keep us from getting hurt. Having a circuit board fail in manufacturing because the components are too close to the edge of the board or because it is too noisy due to the proper trace clearances not being used are extremely frustrating.

Design rules are in place to ensure that the circuit boards we lay out will avoid these problems and function as intended. In this article, we are going to look at some of the key design rules for PCB layout that will help you avoid these potential issues. If you are interested in PCB design, please check and reads the passage.

1. How to create schematic of PCB?

Whether you are generating your design from a template or creating your printed circuit board from scratch, it is probably best to begin with the schematic. Your schematic is similar to the blueprints for your new device, and it is important to understand what is shown in your schematics. First, your schematics show you the following:

· Which components are used in your design

· How components are connected together

· The relationships between groups of components in different schematics

The last point above is quite important, as complex designs may use hierarchical schematics. You can enforce significant organization in your new board if you take a hierarchical approach to your design and place different circuit blocks in different schematics.

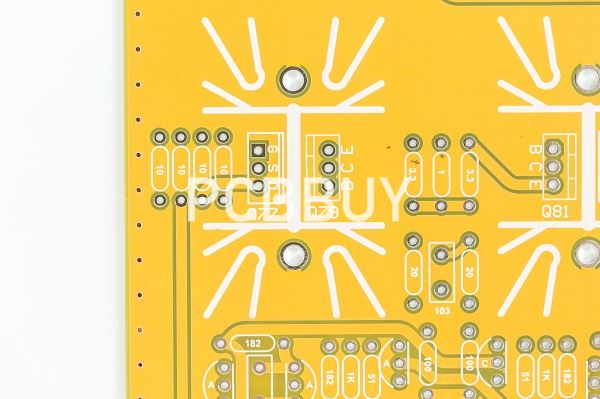

2. How to assign footprint of PCB?

Footprint gives an idea of the actual size of the component. For example, when we put a component on the sand, it will leave its impression there. This imprint is its actual physical size. Some components come in standard packages and the footprints are easy to find. In some cases, we may have to create the footprint manually. Below are the steps to be followed to create a footprint in Altium Designer.

· Create the pads

· Key-in component height and area

· Provide the silk-screen information

· Save the footprint

3. How to calculate the track of PCB?

The tracks are like wires. They are the elements that allow the electric current to flow in your electronic circuit. As we know, the higher the value of the electric current, the larger the section of a conductor must be, so that it can allow the conduction of current.

In the design a PCB, it works with the same principle and therefore, we must perform the proper calculation of the width of the tracks.

For this, we will use software that helps in the process of dimensioning the trails.

You can access the link on the Digikey website and enter the current and temperature parameters for the project. Later, the website will inform the ideal value of the width of your trail. It is important to highlight that the site is safe and uses the equations of the IPC-2221 standard to calculate the width of the tracks: Access the link and calculate the track width

4. How to upgrade PCB design?

With the use of 3D step models, layout teams now have a perspective of PCB design that used to only be possible with mechanical design systems. With the 3D capabilities of CAD tools, PCB designers have a much fuller and comprehensive view of their work, giving them the unique ability to spot unexpected component conflicts and collisions. These tools also give PCB designers the ability to import mechanical design files to check their board against other elements of the entire system design, including other PCBs, cables, and system enclosures.

Design rules for PCB layouts can open up a whole new world by allowing you to push up against the technology envelope, but not go past it. This gives you the freedom to consider all possible scenarios in your design without having to worry whether or not your efforts are in violation of design rules.

5. How to process the routing of PCB?

Once the basic placement has been completed, the next stage of the PCB design is to route the connections between all the components. The PCB software then routes the physical connections on the board according to the netlist from the schematic. To achieve this it will use the number of layers that are available for connections, creating via holes as required. Often one layer will be allocated for use as a ground plane, and another as a power plane. Not only does this reduce the level of noise, but it enables low source resistance connections to be made for the power.

The routing can use a significant amount of computing power. This is particularly true for larger designs where there may be upwards of three or four thousand components. Where routing is difficult as a result of high component density, this can result in the routing taking a significant amount of time.

Industry Category