How to Design Single layer PCB with 5 Effective Tips?

By:PCBBUY 10/08/2021 09:49

The lamination is pretty important to the PCB design process, and it will also affect the performance and supplication of the finished products. Among different type of printed circuit boards, the single-layer printed circuit board is the basic one and quite useful in many applications such as hobby electronics board and also in professional applications such as power supplies, battery chargers, LED lightings, camera circuits, and many more,

In this passage, we will provide you the methods of single layer PCB design. If you are interested in the single layer PCB design, please check and read the content for more information.

What are the 7 tips of single layer PCB design?

1. What are the advantages of single layer PCB?

Simple and easy to design and install

Lower cost, especially for high volume orders

· Easy drilling, soldering, de-soldering and components inserting process

· Lower probability of manufacturing issues,such as short circuiting and producing noise

· Components are installed at only one side, require lower jumper to compensate the circuit

· Popular, common, and easily understood by most PCB manufacturers

· Less time for fault tracing and repairing

2. What are the disadvantages of single layer PCB?

Despite their cost advantages and other perks, single-layer boards are not the right choice for every project due to the limitations they have, which include:

• Simplistic Design: The simplicity of single-layer boards' is one of their biggest benefits, but it's also a substantial limitation.

• Slower Speed and Lower Operating Capacity: The limited number of connections on these boards also affects their power and speed.

• Larger Size and Higher Weight: To add capabilities to a single-sided board, you need to expand its dimensions rather than add another layer, as you could with you a multi-layer PCB.

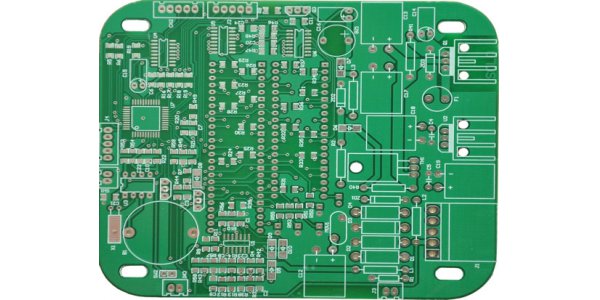

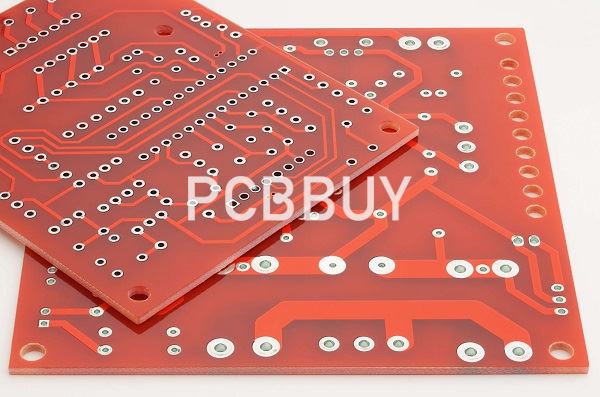

3. What is the construction of single layer PCB?

The base material, which is also known as substrate, is made up of insulating fiber glass that has compact look and PCB strength. What’s more, the type and nature of base material depends on whether the board is flexible PCB or rigid PCB. There is a copper layer which has conducting path for various components on the board above substrate. Needless to say, different boards have different copper thickness according to your needs and demands, defining in ounces per square foot.

One hand, there is a solder mask layer on the top of copper foil. The layer is mainly in protecting the copper foil from insulating which avoids the conduction in case direct contact happens with some conducting material. One the other hand, there is a silkscreen layer on the top of all layers, which is mainly in adding characters and symbols on the board, so it’s easy to have a better understanding of the board.

4. What are the types of single layer PCB?

Some single layer PCBs are currently in used and here we shell explain them with respect to its manufacturing material.

· Single Layer Rigid PCBs: It is the type of a single layer PCB which is made up a rigid material such as fiber glass. These PCBs are inflexible and prevent the circuit from bending and breaking. Currently these are used in different types of devices such as in calculators and power supplies etc.

· Single Layer Flexible PCBs: It is the type of a single layer PCB which is mode out a flexible material instead of a rigid material and for this purpose plastic materials are used. It has so many advantages over single layer rigid pub but it fabrication cost is so much high.

· Single Layer High Frequency PCBs: It is the type of a single layer PCBs which is used for high frequency circuits normally in giga hertz. These PCBs are made out a Teflon or polyphenylene oxide (PPO) material.

5. What is the cost of single layer PCB

The cost of a single-layer PCB depends on various factors. Some of the factors are primary, while some are secondary.

The first thing is the type of base material. You can choose metal, FR-4, PTFE, or any other material. Along with the type of the material, the thickness of the base also matters. Then, it is important to measure the size of the board and circuit. These two are the most important factors in PCB production. After that, you can consider the surface finish, copper thickness, via filling, tracing, holes, and some other factors.

Buyers also require PCB assembly services. In this case, you need to add the cost of the components and testing. The cost of the PCB also depends on the order. High volume orders will give you less cost per piece. So, you can also reduce the cost if you have a bulk order.

Industry Category