How to Design the PCB Board with PCB Design Rules?

By:PCBBUY 05/06/2022 09:18

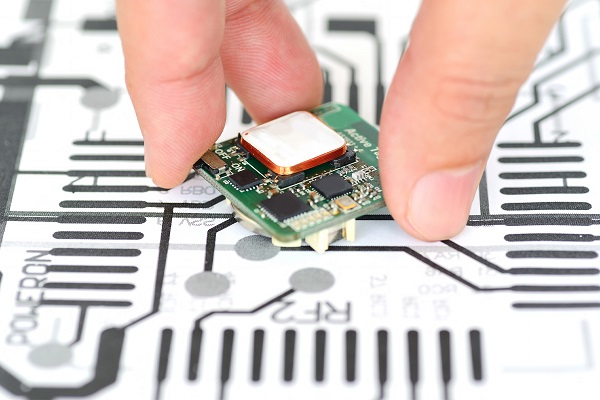

Not only do we need our PCBs to work the way that we’ve designed them too, but those boards must be manufacturable for a reasonable price as well. There are several factors that can contribute to a board not being considered manufacturable.

A PCB design may seem perfectly acceptable when viewed in isolation, but certain design decisions may make assembly difficult later on. Check and read the content below for more information about PCB assembly design rules.

What are the golden rules of PCB design?

Although the current level of semiconductor integration is getting higher and higher, many applications also have system-on-chips available at any time, and many powerful and out-of-the-box development boards are also more and more easily available, but many use cases in electronic products The application still needs to use a custom PCB. In one-time development, even an ordinary PCB can play a very important role. PCB is the physical platform for design and the most flexible part for electronic system design of original components.

Choose the right grid-set and always use the grid spacing that matches the most components.

Although the multi-grid seems to be effective, if engineers can think more in the early stage of PCB layout design, they can avoid the problems encountered in the interval setting and maximize the application of the circuit board. Because many devices use multiple package sizes, engineers should use the product that is most conducive to their own design. In addition, polygon is very important for circuit board copper. Multi-grid circuit boards generally produce polygonal filling deviation when polygonal copper is applied. Although it is not as standard as based on a single grid, it can provide more than the required circuit board life.

Keep the path shortest and most direct.

This sounds simple and common, but it should be kept in mind at every stage, even if it means to change the circuit board layout to optimize the wiring length.

Inspect Traces in your PCB Design

Traces are wire conductors responsible for current flow from one component to another. In your PCB- the solder masks cover up the particles. A good practice to reduce errors is color-coding the masks. Traces of only the top and bottom layers of your PCB designs are visible. The usual solder mask color is green- although other colors are also available. White is difficult to notice.

Errors due to Trace misplacement are common. The usual golden rule is- Keep the trace connections as clean as possible. Traces with sharp bends can be problematic for higher power or frequency transmission. Try to avoid steep 90-degree angles. There are exceptions to this general rule too. PCBs with square concentric spirals are a perfect example. We can find these characteristics of high-quality PCB.

How to meet the requirements of PCB design preparation?

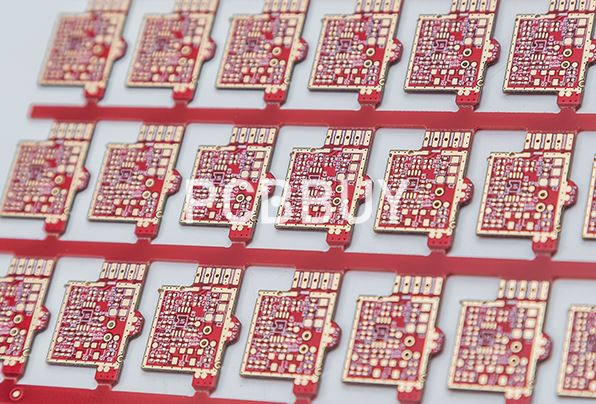

There’s a huge demand in the PCBs market, but not just any boards but quality boards made under the right procedures. PCBs are manufactured once a layout is prepared to attract a huge market. Therefore, designers and manufacturers are under pressure to manufacture boards that promise to bring about desired functionality regularly.

Plenty of PCB manufacturers lately, employ effective tools such as DFM software and PCB design tools to create the best layout plans. Such tools are effective as they bring about the best solutions for creating the best PCB layout. These and many other tools find use in a lot of PCB manufacturing firms since they are cost-effective and functional to PCB designers and manufacturers.

To meet the demands of producing functional PCBs that deliver as desired, many manufacturers are heavily concentrating on having layout prepared first. This includes defining the board's outline, placing the parts together, creating connections between the parts, and exporting them for fabrication. PCB layout preparation matters in producing high-functioning PCBs, a reason why plenty of PCB manufacturers lately consider this matter seriously.

What are the main tips of high-quality PCB design?

Inspect Traces in your PCB Design

Traces are wire conductors responsible for current flow from one component to another. In your PCB- the solder masks cover up the particles. A good practice to reduce errors is color-coding the masks. Traces of only the top and bottom layers of your PCB designs are visible. The usual solder mask color is green- although other colors are also available. White is difficult to notice.

Errors due to Trace misplacement are common. The usual golden rule is- Keep the trace connections as clean as possible. Traces with sharp bends can be problematic for higher power or frequency transmission. Try to avoid steep 90-degree angles. There are exceptions to this general rule too. PCBs with square concentric spirals are a perfect example. We can find these characteristics of high-quality PCB.

Pay attention to the schematic details

Schematics control the project, so accuracy and completeness are critical for success. They include information that is necessary for the proper operation of the circuit. A schematic should include adequate design details, such as pin numbers, names, component values, and ratings.

Embedded within each schematic symbol is the manufacturer part number used to determine price and specifications. The package specification determines the size of the footprint for each component. The first step should be to make sure the exposed copper for each pin is in the proper location and is slightly larger than the component pins (3 to 20 mils) depending on available area and soldering method.

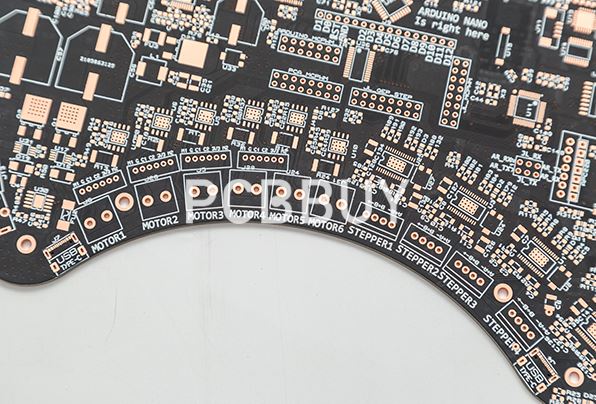

To process the component placement

Component placement is next in the process and determined based on thermal management, function, and electrical noise considerations. A first-pass component placement step commences after the outline of component and interconnect position has been assigned. Immediately after the individual components are placed, a placement review should be held and adjustments made to facilitate routing and optimize performance.

Placement and package sizes are often reconsidered and changes are made at this point based on size and cost. Components absorbing greater than 10 mW or conducting more than 10 mA should be considered powerful enough for additional thermal and electrical considerations. Sensitive signals should be shielded from noise sources with planes and be kept impedance-controlled.

Industry Category