How to Desolder PCB Components?

By:PCBBUY 07/30/2024 16:21

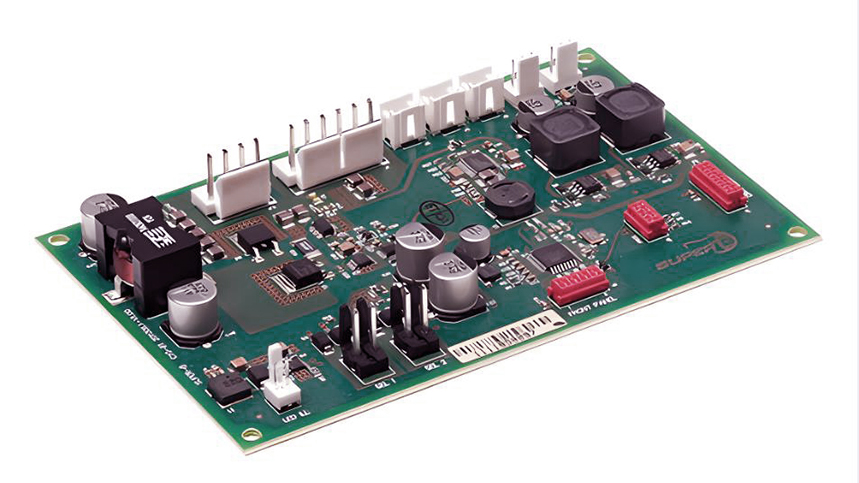

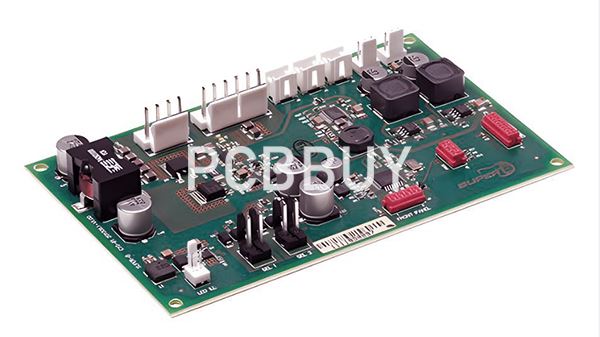

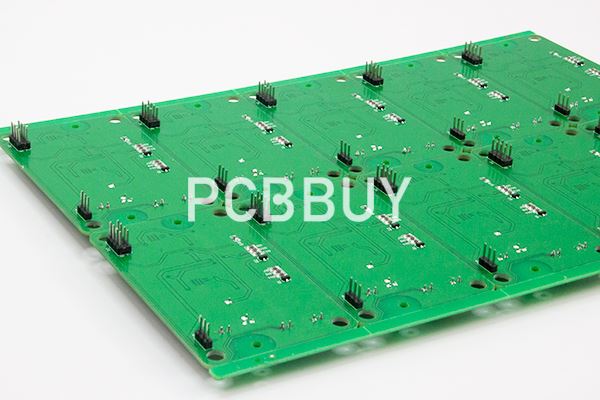

Desoldering components from a printed circuit board (PCB) is a fundamental skill in electronics repair and prototyping. Whether replacing faulty components, correcting mistakes, or salvaging parts, desoldering is essential for maintaining and modifying electronic devices. This article provides an in-depth guide on how to desolder PCB components, covering various techniques, tools, best practices, and considerations for different component types. It also discusses the challenges and solutions associated with desoldering, supported by technical data and industry knowledge.

What Is the Importance of Desoldering in Electronics?

Desoldering is the process of removing solder from electronic components and their pads on a PCB. This is crucial for repairing or replacing components, troubleshooting circuits, and recycling valuable parts. Mastery of desoldering techniques ensures the integrity of both the components and the PCB, preventing damage and maintaining functionality.

Common Applications

Desoldering is commonly used in:

Repair and Maintenance: Fixing or replacing faulty components.

Prototyping and Development: Adjusting circuit designs during testing.

Component Salvage: Recovering usable parts from old or damaged boards.

Rework and Modification: Making changes to existing circuits.

What Are the Tools and Equipment for Desoldering?

Essential Desoldering Tools

1. Soldering Iron

A basic tool with a heated tip used to melt solder.

Typically, a temperature-controlled soldering iron is preferred to prevent overheating components or pads.

|

Tool |

Description |

Best For |

|

Soldering Iron |

Heated tip, various sizes |

General desoldering, small components |

2. Desoldering Pump (Solder Sucker)

A manual tool used to suck up molten solder.

Ideal for removing solder from through-hole components and larger solder joints.

|

Tool |

Description |

Best For |

|

Desoldering Pump |

Handheld, spring-loaded |

Through-hole components, large joints |

3. Desoldering Braid (Wick)

A braided copper wire coated with flux that wicks up molten solder when heated.

Useful for cleaning solder from component leads and pads, particularly in surface-mount technology (SMT) applications.

|

Tool |

Description |

Best For |

|

Desoldering Braid |

Desoldering Braid |

Fine pitch components, SMT rework |

4. Hot Air Rework Station

A device that blows hot air to reflow solder, allowing for the removal of SMT components without direct contact.

Essential for desoldering components with many leads or delicate packages.

|

Tool |

Description |

Best For |

|

Hot Air Station |

Controlled airflow, adjustable temperature |

SMT components, BGA packages |

5. Flux

A chemical cleaning agent that facilitates soldering and desoldering by preventing oxidation.

Flux improves heat transfer and helps solder flow more easily.

|

Tool |

Description |

Best For |

|

Flux |

Flux |

Enhancing solder flow, preventing oxidation |

What Is Advanced Desoldering Equipment?

1. Desoldering Station

Combines a soldering iron with a vacuum pump for efficient solder removal.

Provides precise control over temperature and suction, suitable for high-density PCBs.

|

Tool |

Description |

Best For |

|

Desoldering Station |

Integrated iron and vacuum |

High-density PCBs, professional use |

2. Infrared Reflow Station

Uses infrared radiation to heat specific areas of the PCB product, allowing precise control over the desoldering process.

Suitable for sensitive components and multilayer PCB boards.

|

Tool |

Description |

Best For |

|

Infrared Station |

Non-contact heating |

Sensitive components, multilayer boards |

3. Ultrasonic Solder Removal

Uses ultrasonic vibrations to remove solder without heat.

Ideal for delicate components or situations where heat may cause damage.

|

Tool |

Description |

Best For |

|

Ultrasonic Removal |

Non-thermal solder removal |

Delicate components, sensitive PCBs |

What Are the Techniques for Desoldering PCB Components?

Through-Hole Components

1. Desoldering Pump Method

Heat the solder joint with a soldering iron until the solder melts.

Quickly place the desoldering pump over the molten solder and activate it to suck up the solder.

|

Technique |

Steps |

Best For |

|

Desoldering Pump |

1. Heat joint, 2. Suck solder |

Through-hole, large solder joints |

2. Desoldering Braid Method

Place the desoldering braid on the solder joint and apply the soldering iron on top.

The braid will absorb the molten solder as it wicks into the copper strands.

|

Technique |

Steps |

Best For |

|

Desoldering Braid |

1. Place braid, 2. Apply heat |

Fine pitch, small joints |

3. Desoldering Station Method

Use a desoldering station for precise temperature and suction control.

Apply the heated tip to the joint and activate the vacuum to remove solder.

|

Technique |

Steps |

Best For |

|

Desoldering Station |

1. Heat joint, 2. Vacuum solder |

High-density boards, professional use |

Surface-Mount Technology (SMT) Components

1. Hot Air Rework Method

Set the hot air rework station to the appropriate temperature.

Use the airflow to heat the solder joints evenly, then gently remove the component with tweezers.

|

Technique |

Steps |

Best For |

|

Hot Air Rework |

1. Heat joint, 2. Remove component |

SMT components, BGA packages |

2. Infrared Reflow Method

Position the infrared heater over the component.

Apply controlled heat to reflow the solder, then remove the component.

|

Technique |

Steps |

Best For |

|

Infrared Reflow |

1. Apply heat, 2. Remove component |

Sensitive components, multilayer boards |

3. Soldering Iron and Braid Method

For smaller SMT components, use a fine-tip soldering iron and desoldering braid.

Carefully heat the solder and wick it away with the braid.

|

Technique |

Steps |

Best For |

|

Iron and Braid |

1. Heat joint, 2. Wick solder |

Fine-pitch components, small SMTs |

What Are Best Practices and Considerations?

Temperature Control

Maintaining proper temperature is crucial to avoid damaging the PCB or components. Excessive heat can delaminate the PCB layers or damage sensitive components.

|

Factor |

Best Practice |

|

Temperature |

Use temperature-controlled tools, start at lower settings and increase as needed |

Component Handling

Careful handling of components during desoldering is essential to prevent damage, especially with sensitive or expensive parts. Use appropriate tools like tweezers and avoid excessive force.

|

Factor |

Best Practice |

|

Handling |

Use tweezers, handle components by edges, avoid forceful removal |

Solder and Flux Management

Using fresh solder and flux can facilitate the desoldering process by improving heat transfer and solder flow. Ensure proper cleanup to remove residual flux, which can be corrosive.

|

Factor |

Best Practice |

|

Solder and Flux |

Use fresh solder and flux, clean PCB after desoldering |

Safety Precautions

Desoldering involves high temperatures and potentially harmful fumes. Use appropriate personal protective equipment (PPE), work in a well-ventilated area, and follow safety guidelines.

|

Factor |

Best Practice |

|

Safety |

Wear safety glasses, use fume extractor, work in ventilated space |

What Are the Challenges and Solutions in Desoldering?

Dealing with Stubborn Solder

Stubborn solder joints can be challenging to remove, especially if the solder contains lead-free alloys with higher melting points.

|

Challenge |

Solution |

|

Stubborn Solder |

Increase temperature gradually, use flux to improve solder flow |

Removing Large or Heat-Sensitive Components

Large components or those sensitive to heat require careful handling to prevent damage to the PCB or component itself.

|

Challenge |

Solution |

|

Large/Heat-Sensitive Components |

Use low-temperature methods, preheat PCB if necessary |

Avoiding PCB Damage

Excessive heat or force can damage the PCB, including lifting pads or traces.

Ultrasonic Solder Removal

Ultrasonic solder removal uses high-frequency vibrations to dislodge solder without applying heat, minimizing thermal stress on components.

Laser Desoldering

Laser desoldering utilizes laser energy to precisely target and reflow solder, allowing for the removal of components with minimal impact on surrounding areas.

Robotic Desoldering

Robotic systems equipped with desoldering tools offer automation and consistency, ideal for high-volume or complex rework tasks.

Conclusion

Desoldering is a critical skill in electronics, enabling the repair, modification, and recycling of PCBs. With a wide range of tools and techniques available, selecting the right method for the specific component and PCB type is essential. Proper temperature control, careful handling, and adherence to safety practices ensure successful desoldering without damaging components or the PCB. As technology advances, innovative methods such as ultrasonic and laser desoldering are expanding the possibilities for efficient and precise rework.

References

1. IPC-7711/7721, "Rework, Modification and Repair of Electronic Assemblies," IPC, 2020.

2. J. H. Lau, "Advanced Soldering and Desoldering Techniques," McGraw-Hill, 2003.

3. R. Prasad, "Surface Mount Technology: Principles and Practice," Springer, 2013.

4. G. C. Schwartz, "Handbook of Soldering Technology," ASM International, 2010.

5. "Desoldering Techniques for Lead-Free and Tin-Lead Alloys," Kester Technical Library, 2018.

Industry Category