How to Fix PCB Traces When It’s Broken?

By:PCBBUY 04/27/2022 11:11

A PCB trace acts as a resistor and the longer and narrower the trace, the more resistance is added. If we assume some general things like a 1-ounce copper pour and ambient room-temperature during normal operation, we have what we need to calculate both the minimum trace width and expected voltage drop at that width.

Soldering works by heating metal wires with a soldering iron and then applying the solder to the joint. The solder acts as a glue, whereupon melting, it flows over the metals to be joined and then establishing a connection between the metals. If you are going to learn more information about solder wire on PCB, please check and read the content below in this passage.

Why we have to repair PCB?

Why bother at all with learning component-level board repairs for PCBs? Don’t we live in a throwaway culture in which it’s OK to toss electronics in the landfill at the first sign of trouble?

This is the first reason why it makes so much sense to learn everything that you can about repairing PCBs. People who have a passion for electronics, and for upcycling or getting the maximum lifespan out of something, can find a lot of satisfaction in the process of locating damaged tracks or identifying failed board components, replacing them, and restoring a PCB.

On the hobbyist as well as the professional side of things, an understanding of how PCBs function and how to restore them is essential if you want to learn how to build and maintain your own projects and systems, such as the following:

Garage door openers

Home theater systems

Speed controllers for powered tools

Televisions

Computers

Electrical engineers have even more motivation for pursuing a masterful knowledge of this fundamental skill. Both the consumer and commercial landscape rely on ever more sophisticated electronic devices, most of which require PCBs. Knowing how to diagnose problems with these boards and repair or replace failed components means that a technician can perform troubleshooting on a wide range of computerized assets and internet of things (IoT) devices.

How to identify the broken PCB trace?

The traces on a printed circuit board are pathways that conduct electricity and consist of either copper or silver. PCB trace damage that occurs as a result of physical breakdowns or ongoing use can lead to major problems that affect the parts and conductivity of the printed circuit board and the actual device.

There are different causes of trace damage and these include regular wear and tear, overheating, dust, power surges and lightning. If the trace is not hard to see due to being extremely thin, it is generally possible to identify the damage by examining the pathway.

Since silver and copper are naturally bright and conspicuous elements, they are easy to detect when there is a problem. Fixing damaged or defective pathways involves using the right material to solder the board in order to restore the damaged circuit and enable electricity to flow without disruption through the circuit board.

How to prepare solder broken wire on PCB?

Before we get to the main point, eventually, we would like to suggest useful tips. The re-soldering of wires on the circuit board is similar to what we know about how to solder the electrical wire to the circuit board.

So, you shouldn’t face many issues with the re-soldering process. However, if you have forgotten the soldering process, we will recap the process for re-soldering the damaged or cracked circuit board wires.

Things you will need:

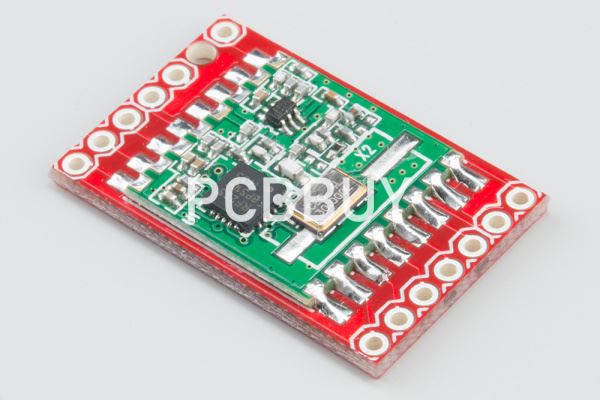

Solder: This is pretty straightforward. You will need a solder for the re-soldering process. These are available in various thicknesses that usually start from 0.02mm. The thick solders are widely used for copper pipe or PCB. It is used with a butane torch. However, you will have to opt for the thin solders for detailing and repairing jobs.

Soldering iron: You will need a quality soldering iron to generate the right amount of soldering temperature. You can opt from the low wattage (15-40W) or high wattage (60-140W) for the soldering process. The low wattage works on circuit boards, and high wattage helps work with braided speaker wire.

How to process solder broken wire on PCB?

Cut the exposed wire to length.

Clean your soldering iron tip. Pre-tin your solder iron tip. On the underside of the board, place the soldering iron so that it touches the metal around the hole and the wire at the same time. Then touch the soldering iron to the pad and wire from the opposite side.

The solder should flow around the pad and wire very quickly. Withdraw the soldering iron. Do not use the soldering iron to melt solder directly and then try to apply it to the pad and wire: solder flows towards heat, and it would rather stay on the soldering iron than transfer to the cooler pad and wire.

Also, it’s not a good idea to clip the wire after soldering as a) you may shock the solder joint so it may fail later, and b) you will be leaving copper exposed on the cut end of the wire.

Clean your soldering iron. Pre-tin your soldering iron. You are now ready for the next wire.

·

Industry Category